GB Equal Structural Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000T/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

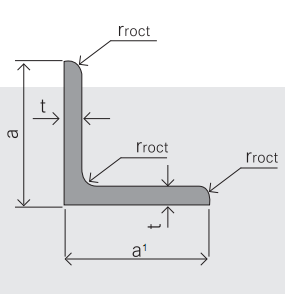

Specifications of GB Equal Structural Angle

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m

3. Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400;

SS540.

4.Sizes:

|

Sizes: 25mm-250mm | ||

|

a*t | ||

|

25*2.5-4.0 |

70*6.0-9.0 |

130*9.0-15 |

|

30*2.5-6.6 |

75*6.0-9.0 |

140*10-14 |

|

36*3.0-5.0 |

80*5.0-10 |

150*10-20 |

|

38*2.3-6.0 |

90*7.0-10 |

160*10-16 |

|

40*3.0-5.0 |

100*6.0-12 |

175*12-15 |

|

45*4.0-6.0 |

110*8.0-10 |

180*12-18 |

|

50*4.0-6.0 |

120*6.0-15 |

200*14-25 |

|

60*4.0-8.0 |

125*8.0-14 |

250*25 |

5. Material details:

|

Alloy No |

Grade |

Element (%) |

|||||

|

C |

Mn |

S |

P |

Si |

|||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045 |

≤0.3 |

|

|

|

|

|

|

|

|

|

|

|

Alloy No |

Grade |

Yielding strength point( Mpa) |

|||||

|

Thickness (mm) |

|||||||

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

||||

|

≥ |

|||||||

|

|

|

|

|

|

|

||

|

Q235 |

B |

235 |

225 |

215 |

205 |

||

|

Alloy No |

Grade |

Tensile strength (Mpa) |

Elongation after fracture (%) |

||||

|

Thickness (mm) |

|||||||

|

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

|||

|

≥ |

|||||||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

375--500 |

26 |

25 |

24 |

23 |

|

Usage & Applications of GB Equal Structural Angle

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of GB Equal Structural Angle

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: What are the different methods of fire protection for steel angles?

- There are several different methods of fire protection for steel angles, depending on the specific requirements and regulations. Some common methods include: 1. Passive Fire Protection: This involves applying fire-resistant materials directly to the steel angles. These materials can include fire-resistant coatings, fireproofing sprays, or intumescent paints. These coatings can help delay the spread of fire and provide insulation, protecting the steel angles from the high temperatures produced during a fire. 2. Encasement: Another method is to encase the steel angles in fire-resistant materials such as concrete or gypsum board. This creates a barrier between the steel and the fire, preventing it from reaching critical temperatures that could cause structural failure. 3. Fireproofing Systems: Fireproofing systems involve the use of fire-resistant boards or panels that are attached to the steel angles. These systems provide a layer of insulation and protection against fire, preventing the steel from heating up quickly and maintaining its structural integrity for a longer period. 4. Sprinkler Systems: Installing sprinkler systems can also help protect steel angles from fire. These systems are designed to detect and suppress fires by releasing water or fire-suppressing agents when triggered. By quickly extinguishing the fire, the sprinklers can prevent the steel angles from reaching critical temperatures. 5. Fire-resistant barriers: Fire-resistant barriers, such as fire-resistant walls or curtains, can be utilized to separate steel angles from potential fire sources. These barriers can help contain the fire and prevent it from spreading to the steel angles, providing an additional layer of protection. It is important to consult with fire protection experts, engineers, and local building codes to determine the most suitable method of fire protection for steel angles in a specific setting. The choice of method may depend on factors such as the type of building, fire safety requirements, and the level of fire risk involved.

- Q: How do steel angles perform in terms of electrical conductivity?

- Steel angles, being made of steel, typically have poor electrical conductivity. Steel is a poor conductor of electricity compared to materials like copper or aluminum. This is due to the high resistance of the steel material, which inhibits the flow of electrons. Therefore, steel angles are not commonly used for electrical applications that require good electrical conductivity. However, steel angles can still be used in certain electrical applications where conductivity is not a critical factor, such as providing structural support in electrical installations.

- Q: How do steel angles perform in terms of impact resistance?

- Steel angles have a strong performance when it comes to resisting impacts. Their structural design allows them to withstand high impact forces and distribute them evenly along their length. This quality makes them suitable for various applications, including construction, industrial machinery, and automotive frames, where impacts or dynamic loads are expected. The excellent impact resistance of steel stems from its high strength and toughness. Steel angles are typically made from low carbon steel or alloy steel, both known for their high tensile strength and ability to absorb energy without breaking. As a result, steel angles can resist deformation and maintain their structural integrity even under heavy impacts. Furthermore, the impact resistance of steel angles can be further enhanced by using specific steel grades or applying surface treatments like galvanization or powder coating. These treatments not only improve the corrosion resistance of steel angles but also enhance their overall durability, making them even more resistant to impacts and harsh environmental conditions. However, it is essential to note that the impact resistance of steel angles can vary depending on factors like dimensions, thickness, and material properties. Therefore, it is recommended to consult with a structural engineer or refer to technical specifications provided by manufacturers to ensure that the chosen steel angle is suitable for the intended application and expected impact loads.

- Q: Are steel angles resistant to fire?

- Fire resistance is generally attributed to steel angles. Steel, being a non-combustible substance, does not burn or aid in the propagation of fire. However, it should be noted that while steel itself is fire-resistant, it can lose its strength when exposed to prolonged high temperatures. In the event of a fire, the temperature can rise rapidly and cause the steel to weaken, potentially compromising the structural integrity of a building or component. To improve fire resistance, fire-resistant coatings such as intumescent paint or fireproofing materials can be applied to steel angles. These coatings offer additional insulation, delaying the steel's exposure to high temperatures and preventing failure. Ultimately, the fire resistance of steel angles depends on several factors, including the duration and intensity of the fire, as well as the measures taken to enhance their fire performance. To ensure the appropriate level of fire resistance for steel angles in a specific application, it is crucial to consult with fire protection experts and adhere to building codes and regulations.

- Q: Can steel angles be used for manufacturing vehicle frames?

- Yes, steel angles can be used for manufacturing vehicle frames. Steel angles provide structural support and are commonly used in the construction of vehicle frames due to their strength, durability, and ability to withstand heavy loads.

- Q: Can steel angles be used for balcony railings?

- Indeed, balcony railings can be crafted with steel angles. These angles are frequently employed in construction due to their robustness and resilience. They offer essential structural reinforcement and can be conveniently tailored to accommodate the precise measurements and design specifications of a balcony railing. Furthermore, steel angles can be adorned with paint or coatings to harmonize with the desired aesthetic of the balcony. Nevertheless, it is imperative to verify that the steel angles employed adhere to the essential safety regulations and building codes to safeguard the stability and security of the balcony railing.

- Q: How do you determine the required angle size for a specific load?

- To determine the required angle size for a specific load, several factors need to be considered. Firstly, the weight of the load must be determined. This can be done by measuring the mass of the object or by consulting relevant engineering specifications. Secondly, the angle of inclination or the slope at which the load will be placed needs to be known. The angle of inclination will affect the force exerted on the angle, as well as the stability of the load. Next, the type and material of the angle being used should be considered. Different materials have different load-bearing capacities, and the type of angle (e.g., steel, aluminum, or wood) will dictate the maximum load it can support. Additionally, the length of the angle and the number of supporting points should be taken into account. Longer angles may require additional support to distribute the load evenly and prevent bending or deformation. Once all these factors are determined, calculations can be made using engineering formulas and principles. These calculations will consider the weight of the load, the angle of inclination, and the material properties of the angle to determine the required angle size. It is important to note that when designing for safety, engineers usually include a factor of safety to ensure the angle can handle loads beyond the expected maximum. This factor accounts for variables such as dynamic loads, unforeseen circumstances, and wear and tear over time. In conclusion, determining the required angle size for a specific load involves considering the weight of the load, the angle of inclination, the material properties of the angle, the length of the angle, and the number of supporting points. Through calculations and incorporating a factor of safety, the appropriate angle size can be determined to ensure the load is supported safely and effectively.

- Q: Are steel angles suitable for high-temperature applications?

- No, steel angles are not suitable for high-temperature applications. Steel angles are typically made from carbon steel, which starts to lose its strength and structural integrity at elevated temperatures. At high temperatures, carbon steel undergoes a process called thermal expansion, where it expands and becomes weaker. This can lead to deformations and structural failures in the steel angles. For high-temperature applications, materials such as stainless steel or alloys with higher heat resistance, such as Inconel or Hastelloy, are more suitable. These materials can withstand higher temperatures without significant loss of strength and structural stability.

- Q: What is the maximum slope for a steel angle?

- The maximum slope for a steel angle depends on various factors such as the size, shape, and thickness of the angle. However, in general, steel angles are designed to withstand vertical loads and provide stability in structural applications. Therefore, the maximum slope for a steel angle is typically limited to angles less than 45 degrees. Going beyond this angle may compromise the structural integrity of the angle and increase the risk of failure. It is important to consult engineering codes, standards, and specifications to determine the specific maximum slope for a particular steel angle in a given application.

- Q: Can steel angles be used for artistic or decorative applications?

- Yes, steel angles can definitely be used for artistic or decorative applications. Steel angles are versatile and can be manipulated and shaped to create unique and visually appealing designs. They can be used to create sculptures, decorative metalwork, decorative brackets, and architectural elements. Steel angles can be painted, polished, or finished in different ways to enhance their aesthetic appeal. Their strength and durability make them suitable for both indoor and outdoor artistic applications. Additionally, steel angles can be welded or joined together to create complex and intricate designs. Overall, steel angles offer artists and designers a wide range of possibilities for creating beautiful and decorative pieces.

1. Manufacturer Overview

| Location | Tangshan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$ 300 Million |

| Main Markets | Middle East; Korea; Southeast Aisa |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 70% - 80% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 900,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

GB Equal Structural Angle Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000T/Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords