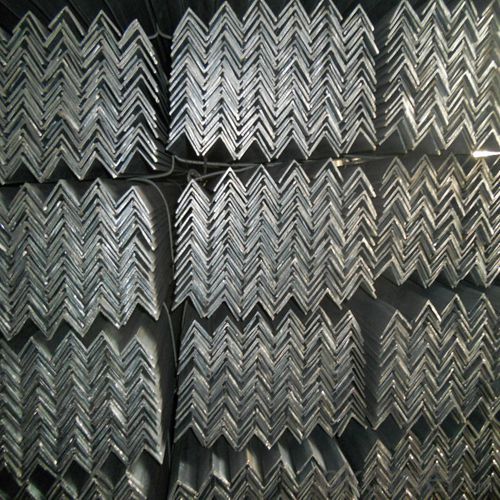

Hot Rolled Steel Bar Equal Bar Unequal Bar Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Bar Equal Bar Unequal Bar Q235 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Bar Equal Bar Unequal Bar Q235 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Bar Equal Bar Unequal Bar Q235 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the typical lengths of steel angles?

- The typical lengths of steel angles vary depending on the specific application and industry standards. However, common lengths for steel angles range from 20 to 40 feet.

- Q: Can steel angles be used for cable trays?

- Indeed, cable trays can employ steel angles. By virtue of their strength and support, steel angles prove suitable for both cable retention and the establishment of a steadfast framework for cable trays. The inflexible and resilient attributes of steel angles guarantee the cable trays' capacity to withstand the cables' weight and any supplementary burdens. Moreover, steel angles allow for effortless fabrication and customization to cater to specific needs, rendering them an adaptable option for cable tray installations.

- Q: Are steel angles suitable for constructing bridges?

- Indeed, bridges can be constructed using steel angles. Due to their strength and versatility, steel angles are frequently employed in bridge construction. They can easily be fashioned into different forms and dimensions, making them well-suited for crafting structural elements like beams, columns, and trusses. Moreover, steel angles possess exceptional tensile strength, enabling them to endure the weighty loads and forces endured by bridges. Furthermore, steel angles boast excellent resistance to corrosion, guaranteeing the endurance and resilience of bridge structures. In summary, steel angles represent a dependable and economical option for bridge construction.

- Q: Can steel angles be used for support brackets in electrical installations?

- Yes, steel angles can be used for support brackets in electrical installations. Steel angles are commonly used in construction and can provide sturdy support for various applications, including electrical installations. They are strong, durable, and can withstand the weight and stress associated with supporting electrical components or fixtures. Steel angles can be easily mounted to walls, ceilings, or other surfaces, providing a stable base for electrical equipment such as junction boxes, conduit, or cable trays. Additionally, steel angles can be customized and fabricated to meet specific installation requirements, making them a versatile choice for support brackets in electrical installations.

- Q: Are there any limitations or restrictions on the use of steel angles in certain applications?

- Indeed, certain applications impose limitations and restrictions on the utilization of steel angles. One such limitation pertains to the maximum load-bearing capacity of these steel angles. Depending on factors like size, thickness, and quality, their ability to support heavy loads may be limited. Consequently, in scenarios requiring high strength and load-bearing capacity, alternative structural members like steel beams or columns may be more suitable. Another restriction concerns the suitability of steel angles for specific shapes or configurations. Generally L-shaped, steel angles are versatile and commonly employed across various applications; however, they may not be ideal for intricate or curved designs. In such instances, custom-shaped structural members or different materials may prove more appropriate. Furthermore, the corrosion resistance of steel angles poses limitations in certain environments. Steel is vulnerable to rust and corrosion, particularly in marine or highly humid conditions. To combat this, additional protective measures such as coatings or the use of stainless steel angles may be necessary in applications where exposure to moisture or corrosive substances is inevitable. Lastly, the fabrication and installation processes for steel angles can also impose limitations. Often necessitating welding, cutting, or drilling during fabrication, these procedures can present challenges in applications requiring precision and specialized equipment. Additionally, the size and weight of steel angles may hinder transportation and installation, particularly in restricted spaces or areas with limited access. Given these limitations and restrictions, it is crucial to carefully consider them when selecting steel angles for specific applications. This ensures that the chosen steel angles meet the required strength, shape, corrosion resistance, and installation specifications.

- Q: How do steel angles contribute to the overall sustainability of a building?

- A building's overall sustainability is enhanced by steel angles in various ways. To begin with, steel angles are constructed from recycled materials, making them a sustainable choice for building purposes. Steel is one of the world's most recycled materials, boasting a high recycling rate. This reduces the necessity for new resources and lessens the environmental impact of extraction and production. Additionally, steel angles offer structural efficiency, enabling them to support greater loads with less material compared to other building materials. This efficiency reduces the amount of steel needed for construction, minimizing the carbon footprint associated with steel production and transportation. Furthermore, steel angles are extremely durable and long-lasting. They possess high resistance to corrosion, fire, and pests, thereby reducing the maintenance and replacement requirements over the building's lifespan. This durability results in reduced waste generation and lower life-cycle costs, ultimately making the building more sustainable in the long term. Moreover, steel angles are versatile and easily reusable or repurposed. In the event of renovation or demolition, salvaging and reusing the steel angles in other construction projects is feasible. This promotes a circular economy approach, minimizing waste generation and contributing to the overall sustainability of the construction industry. Lastly, steel angles possess excellent thermal properties that can enhance a building's energy efficiency. They can be utilized as part of the building envelope, aiding in the reduction of energy consumption for heating and cooling. By improving insulation and airtightness, steel angles contribute to lower energy demand and reduced greenhouse gas emissions. In conclusion, steel angles contribute to a building's overall sustainability through their recycled content, structural efficiency, durability, recyclability, and energy-saving properties. Opting for steel angles in construction allows for resource conservation, waste reduction, and a minimized environmental impact in the built environment.

- Q: What are the cost considerations for using steel angles?

- There are several cost considerations to take into account when using steel angles. Firstly, the cost of the steel material itself can vary depending on the grade and quality of the steel. Higher-grade steel angles tend to be more expensive, but they offer better strength and durability. Additionally, the length and size of the steel angles will affect the overall cost. Longer and larger angles will generally be more expensive due to the increased amount of steel required. It is important to carefully assess the required dimensions to avoid unnecessary costs. Another cost consideration is the fabrication and finishing of the steel angles. If custom fabrication or special finishing techniques are required, such as welding, cutting, or painting, these processes can add to the overall cost. It is essential to factor in these additional expenses when budgeting for the use of steel angles. Transportation costs should also be considered. Steel angles are heavy and bulky, which can lead to higher shipping costs, especially for long distances. It is crucial to account for these expenses, particularly if the project requires a significant quantity of steel angles. Lastly, it is important to consider the long-term costs associated with steel angles. While steel is durable and long-lasting, it may require maintenance or protective coatings to prevent corrosion over time. These maintenance costs should be factored into the overall budget to ensure the longevity and reliability of the steel angles. Overall, the cost considerations for using steel angles include the price of the steel material, the dimensions and size of the angles, fabrication and finishing processes, transportation expenses, and long-term maintenance costs. Evaluating and planning for these factors will help ensure a cost-effective and successful use of steel angles in various applications.

- Q: What are the weight per meter calculations for steel angles?

- The weight per meter calculations for steel angles depend on the dimensions of the angle and the density of the steel being used. To calculate the weight per meter of a steel angle, you need to know the dimensions of the angle, specifically the thickness, width, and length. The formula to calculate the weight per meter is: Weight per meter = (Thickness x Width x Length) x Density The density of steel varies depending on the type of steel being used. The most common type of steel used for angles is mild steel, which has a density of approximately 7.85 grams per cubic centimeter (g/cm³) or 7850 kilograms per cubic meter (kg/m³). For example, let's say we have a steel angle with a thickness of 10 millimeters (mm), a width of 100 mm, and a length of 1 meter (1000 mm). Using the formula and assuming a density of 7850 kg/m³, the weight per meter would be: Weight per meter = (10 mm x 100 mm x 1000 mm) x 7850 kg/m³ Weight per meter = 10,000,000 mm³ x 7850 kg/m³ Weight per meter = 78,500,000,000 mm³/kg To convert the weight to a more common unit, we can divide by 1,000,000 to get the weight per meter in kilograms: Weight per meter = 78,500,000,000 mm³/kg / 1,000,000 Weight per meter = 78,500 kg/m Therefore, the weight per meter of this steel angle would be 78,500 kilograms.

- Q: What are the different types of steel angles used in agricultural applications?

- There are several types of steel angles commonly used in agricultural applications, including L-shaped angles, C-shaped angles, and T-shaped angles. These angles are often used to provide structural support, reinforce joints, or serve as framing components in buildings, equipment, or fencing systems on farms.

- Q: How do you prevent steel angles from rusting in high humidity environments?

- To prevent steel angles from rusting in high humidity environments, a common approach is to apply a protective coating like paint or epoxy. This creates a barrier between the steel and moisture, preventing direct contact and inhibiting rust formation. Additionally, regular inspections and maintenance, such as cleaning and reapplying the protective coating when necessary, can help ensure the longevity of the steel angles in such conditions.

Send your message to us

Hot Rolled Steel Bar Equal Bar Unequal Bar Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords