Hot Rolled Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Heavy Steel Rails for Rails of Tren GB38KG, GB43KG at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Heavy Steel Rails for Rails of Tren GB38KG, GB43KG is suitable for the laying of main trunk line of the curves and the orbit of the tunnel, can also be used for tower crane and other crane track. For example: railway, subway, transportation track, express, curve way, tunnel way.

Product Advantages:

OKorder's Hot Rolled Heavy Steel Rails for Rails of Tren GB38KG, GB43KG are durable, strong, and resist corrosion. And they are made of high quality of steel billets.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

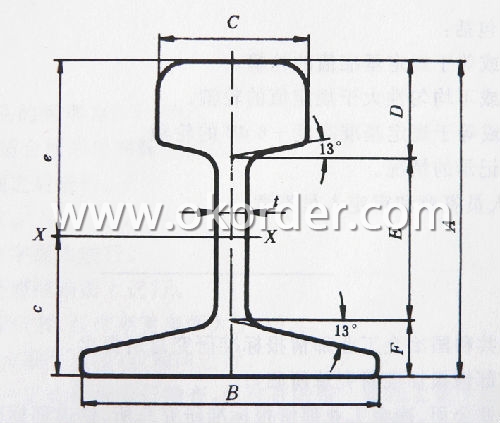

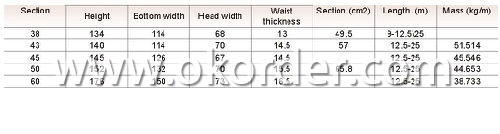

Specificaions of Hot Rolled Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

Production Standard: GB2585-81

Material: 50Mn, U71Mn

Grade | Element(%) | ||||

C

| Mn | S

| P

| Si

| |

50Mn |

0.48—0.56 |

0.70—1.00 |

≤0.035 |

≤0.035

|

0.17-0.37 |

U71Mn | 0.65—0.76 | 1.10—1.40 | ≤0.030 | ≤0.030 | 0.15-0.35 |

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg

Length: 10m, 12m, 12.5m or as the requriement of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Packaging & Delivery of Hot Rolled Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Ms Heavy Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Production flow of Hot Rolled Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

Inspection of Hot Rolled Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: How do we guarantee the quality of Hot Rolled Heavy Steel Rails for Rails of Tren GB38KG, GB43KG?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: What is the normal tolerance of Hot Rolled Heavy Steel Rails for Rails of Tren GB38KG, GB43KG?

A2: Normally 3%-5%, but we can also produce the goods according to the customers' requests.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: Are steel rails prone to buckling under extreme heat?

- Steel rails are susceptible to buckling in extreme heat. When steel is subjected to high temperatures, it expands and contracts as it cools. If the temperature of the steel rail rises significantly, its expansion may cause it to buckle or become distorted. This occurrence is referred to as thermal buckling. The rail's expansion can generate compression forces that surpass its ability to endure, resulting in deformation and possibly even failure. To prevent buckling, railways employ several measures, including the installation of expansion joints, the utilization of continuous welded rail, and the regular monitoring of rail temperatures to guarantee safety and avoid accidents.

- Q: Can steel rails withstand extreme temperatures?

- Yes, steel rails can withstand extreme temperatures. Steel is known for its exceptional strength and durability, making it suitable for various applications, including railway tracks. Steel rails are designed to withstand extreme temperatures, both high and low. Steel has a high melting point, which means it can resist high temperatures without deforming or melting. Additionally, steel has excellent thermal conductivity, allowing it to quickly dissipate heat and prevent excessive expansion or contraction. This property helps steel rails maintain their structural integrity even in extreme temperature conditions. Furthermore, steel is also resistant to cold temperatures, preventing it from becoming brittle or prone to cracking in freezing conditions. Overall, steel rails are specifically engineered to withstand extreme temperatures and provide a reliable and safe transportation system.

- Q: Can steel rails be used in monorail systems?

- Yes, steel rails can be used in monorail systems. Steel rails are commonly used in the construction of monorails due to their durability, strength, and ability to support heavy loads.

- Q: What are the main causes of rail buckling in steel rails?

- The main causes of rail buckling in steel rails can be attributed to factors such as temperature changes, excessive train speed, inadequate maintenance, and poor track geometry.

- Q: Can steel rails be used in freight railways?

- Yes, steel rails are commonly used in freight railways. Steel rails offer several advantages over other types of rail materials, making them an ideal choice for heavy-duty freight transportation. Steel rails are durable, strong, and can withstand the immense weight and pressure exerted by freight trains. They also have excellent resistance to wear and tear, ensuring a longer lifespan and reduced maintenance costs. Additionally, steel rails have good conductivity, allowing for efficient power transmission between the train and the tracks. Overall, steel rails are a reliable and widely used option for freight railways due to their strength, durability, and cost-effectiveness.

- Q: How do steel rails contribute to reducing track maintenance frequency?

- Steel rails contribute to reducing track maintenance frequency in several ways. Firstly, steel rails are highly durable and resistant to wear and tear, which means they can withstand heavy loads and frequent train traffic without needing frequent replacements. This reduces the need for regular maintenance and replacements of the rails themselves. Secondly, steel rails have a smooth and consistent surface, which ensures better contact between the train wheels and the track. This minimizes the occurrence of wheel slippage and reduces the stress on the track, leading to less track damage and decreased maintenance requirements. Lastly, steel rails have excellent strength and stability, which helps maintain the track alignment and prevents deformation or misalignment due to temperature changes or heavy loads. Overall, the use of steel rails significantly reduces the frequency of track maintenance, resulting in cost savings and improved efficiency in railway operations.

- Q: Are steel rails affected by changes in humidity or moisture levels?

- Yes, steel rails can be affected by changes in humidity or moisture levels. When exposed to high levels of moisture or humidity, steel rails can corrode, leading to degradation and structural integrity issues. Regular maintenance and protective measures such as coatings or galvanization are implemented to minimize these effects and ensure the longevity of the rails.

- Q: How do steel rails contribute to train derailment prevention?

- The prevention of train derailments is heavily reliant on the utilization of steel rails, which serve as a secure and dependable track foundation. Here are several ways in which steel rails contribute to the prevention of derailments: 1. Strength and durability: Steel rails possess the necessary design features to endure substantial loads and continuous wear and tear. Their exceptional tensile strength guarantees the ability to bear the weight of trains, thereby averting any bending or fracturing under pressure. This durability significantly diminishes the likelihood of rail failures that may result in derailments. 2. Track alignment: Steel rails are meticulously crafted to maintain precise track alignment. The rails are manufactured to be straight and parallel, ensuring that train wheels remain on the track. Deviations in alignment can lead to derailments. By maintaining accurate track alignment, steel rails effectively minimize the risk of derailments arising from track irregularities. 3. Resistance to deformation: Steel rails exhibit a remarkable resistance to deformation, enabling them to endure heavy loads without significant bending or warping. This resistance to deformation plays a pivotal role in preventing derailments, as it aids in preserving the shape and stability of the track. Even in extreme temperatures, steel rails are less likely to expand or contract, thereby reducing the risk of derailments caused by track distortion. 4. Regular maintenance: The integrity and safety of steel rails necessitate regular inspection and maintenance. Through routine procedures such as track inspections, rail grinding, and the replacement of worn-out rails, potential issues like rail cracks, worn joints, or loose fasteners can be promptly identified and addressed. This proactive approach to maintenance effectively prevents derailments by ensuring the track remains in optimal condition. 5. Weight distribution: Steel rails effectively distribute the weight of trains evenly, thereby minimizing stress on individual sections of the track. This mitigates excessive wear and tear on specific areas, consequently reducing the risk of rail failure and derailments. By uniformly distributing the load, steel rails significantly contribute to the overall stability and safety of the track. In conclusion, steel rails play an indispensable role in preventing train derailments by virtue of their strength, durability, accurate alignment, resistance to deformation, and even weight distribution. Regular maintenance and inspections also aid in identifying potential issues and ensuring the track remains safe for train operations.

- Q: What is the role of steel rails in ensuring train stability?

- The presence of steel rails is vital for maintaining the stability of trains, as they serve as a solid foundation for the train to travel on. By evenly distributing the weight of the train, these rails help to maintain balance and prevent the train from derailing. One of the primary functions of steel rails is to guide the train and ensure that it stays on track. The rails have a specific design, featuring a flange on the inside of the railhead that fits into the groove of the train's wheels. This flanged wheel-rail interaction plays a crucial role in keeping the train aligned and preventing any deviations from the track. Moreover, steel rails provide a smooth and continuous surface for the train to move on. This smooth surface reduces the friction between the train's wheels and the rails, enabling the train to travel at high speeds with minimal resistance. Additionally, this smoothness minimizes vibrations and bumps, providing passengers with a comfortable ride. Aside from stability, steel rails also contribute to the overall safety of train operations. They are designed to withstand heavy loads and resist wear and tear. Regular maintenance and inspections ensure that any defects or damages to the rails are promptly identified and repaired, thus preventing accidents and ensuring the safe passage of trains. In summary, steel rails are indispensable for train stability as they guide the train, evenly distribute its weight, minimize friction, and provide a safe and smooth surface for the train to travel on. Without steel rails, trains would face challenges in maintaining stability and safety, making them an essential component of railway infrastructure.

- Q: What is the maximum load capacity of a steel rail?

- The maximum load capacity of a steel rail depends on various factors such as its dimensions, quality, and design. It can range from a few tons to several hundred tons, depending on the specific application and intended use.

Send your message to us

Hot Rolled Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords