Reinforcing Bars Hot Rolled Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Reinforcing Bars Hot Rolled Steel Bar

Description of Reinforcing Bars Hot Rolled Steel Bar

1, Diameter: 5.5mm-10mm Reinforcing Bars Hot Rolled Steel Bar

10m- 40mm Reinforcing Bars Hot Rolled Steel Bar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Reinforcing Bars Hot Rolled Steel Bar

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

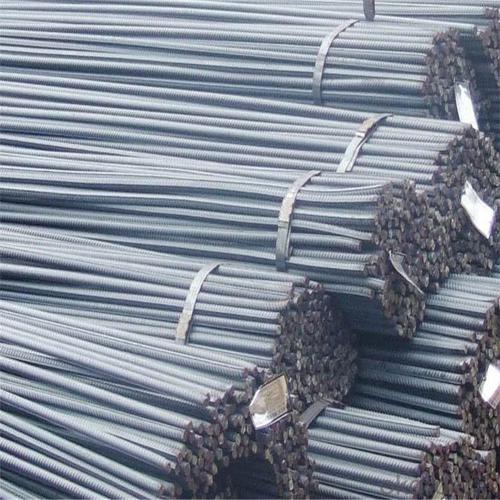

Products Show of Reinforcing Bars Hot Rolled Steel Bar

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the most common alloys used in special steel?

- The most common alloys used in special steel include stainless steel, tool steel, and high-speed steel.

- Q: How does special steel contribute to the marine machinery industry?

- The marine machinery industry greatly relies on special steel, which offers numerous advantages and contributes significantly to the efficiency and reliability of marine machinery. Above all else, special steel is renowned for its exceptional strength and durability. In the harsh marine environment, where machinery is constantly exposed to extreme weather conditions and high levels of corrosion, special steel ensures that marine machinery can withstand these challenges and maintain its integrity over a prolonged period. This enhanced durability not only extends the lifespan of marine machinery but also reduces the frequency of repairs and replacements, thereby resulting in cost savings for shipbuilders and operators. Furthermore, special steel possesses excellent welding and fabrication properties, making it easier to construct complex components of marine machinery. The ability to weld and fabricate special steel allows for the production of intricate and customized parts, which can be tailored to meet the specific requirements of different marine vessels. This design flexibility ensures that marine machinery is optimized for performance, efficiency, and safety. Moreover, special steel exhibits outstanding resistance to corrosion and erosion, which are common problems in marine environments due to saltwater and other corrosive agents. By utilizing special steel, marine machinery can effectively resist corrosion, preventing premature failure and reducing the need for maintenance. This corrosion resistance also enhances the overall safety of marine operations by significantly reducing the risk of machinery malfunction due to corrosion-related issues. In terms of efficiency, special steel contributes to the marine machinery industry by offering superior heat resistance and thermal conductivity. This enables marine machinery to operate at high temperatures without compromising performance, ensuring efficient energy conversion and optimal functioning of critical systems. The improved thermal properties of special steel also contribute to the overall fuel efficiency of marine vessels, resulting in reduced operational costs and environmental impact. In conclusion, special steel plays a vital role in the marine machinery industry by providing the necessary strength, durability, corrosion resistance, and thermal properties for the efficient and reliable operation of marine machinery. By harnessing the benefits of special steel, shipbuilders and operators can enhance the longevity, safety, and performance of marine vessels, ultimately contributing to the growth and sustainability of the marine industry.

- Q: What are the main factors affecting the toughness of special steel?

- The toughness of special steel is influenced by several main factors, namely its composition, microstructure, and heat treatment. Composition is a key determinant of toughness, as certain alloying elements like chromium, molybdenum, nickel, and vanadium can enhance the steel's toughness by forming solid solutions or precipitates that impede crack propagation and improve fracture resistance. Microstructure also plays a significant role in determining toughness. The size, shape, and distribution of different phases in the steel, such as ferrite, pearlite, bainite, and martensite, impact its toughness. Fine-grained microstructures generally exhibit higher toughness due to their increased resistance to crack propagation. Heat treatment is another essential factor for controlling toughness. By subjecting the steel to heating and cooling processes, its microstructure can be altered, thereby affecting toughness. Common heat treatments like quenching, tempering, and annealing are employed to enhance steel toughness. For instance, quenching and tempering can produce a microstructure that possesses a desirable balance of hardness and toughness. Additional factors that can influence toughness include the presence of impurities, non-metallic inclusions, and residual stresses. Impurities and inclusions can act as stress concentrators, reducing the steel's toughness. Furthermore, residual stresses, which may arise during manufacturing, can create regions of high stress that initiate crack formation and impact toughness. In conclusion, the factors of composition, microstructure, heat treatment, impurities and inclusions, and residual stresses are crucial in determining the toughness of special steel. Understanding and controlling these factors are vital for optimizing the toughness and performance of special steels in various applications.

- Q: Can special steel be used in the production of precision instruments?

- Yes, special steel can be used in the production of precision instruments. Special steel alloys often possess enhanced strength, durability, and resistance to corrosion, making them suitable for manufacturing precision instruments that require high precision and performance standards.

- Q: How is special steel used in the production of turbine blades?

- Special steel is used in the production of turbine blades due to its exceptional strength, heat resistance, and corrosion resistance properties. This high-quality steel allows turbine blades to withstand the extreme conditions within a turbine, including high temperatures and rotational speeds. Additionally, the unique composition of special steel enables the blades to maintain their shape and structural integrity, ensuring optimal performance and longevity in power generation applications.

- Q: How does special steel contribute to the magnetic properties of products?

- Special steel contributes to the magnetic properties of products through its unique composition and structure. Special steel, also known as alloy steel, contains specific elements such as nickel, chromium, manganese, and molybdenum, which alter its magnetic behavior. These elements can enhance or suppress the magnetism of the steel, depending on the desired application. For example, when nickel is added to steel, it increases its magnetic permeability, making it more receptive to magnetic fields. This property is particularly useful in applications like transformers, where the steel core needs to efficiently conduct magnetic flux. Similarly, the addition of other magnetic elements like cobalt or iron can also enhance the magnetic properties of special steel. On the other hand, certain elements can reduce or eliminate the magnetic properties of steel. Chromium, for instance, is known for its anti-magnetic characteristics. By adding chromium to steel, it can decrease its magnetic permeability, making it suitable for applications that require non-magnetic qualities, such as medical equipment or electronics. Furthermore, the structure of special steel also plays a crucial role in its magnetic properties. Through various heat treatment processes, the steel's crystalline structure can be manipulated, affecting its magnetization. For instance, by annealing the steel, the crystal grains can be made larger, reducing its magnetization. Conversely, cold working or quenching the steel can lead to a finer grain structure, enhancing its magnetic properties. In summary, special steel contributes to the magnetic properties of products by incorporating specific elements that either enhance or suppress magnetism, depending on the application requirements. Additionally, the steel's structure can be modified through heat treatments, further influencing its magnetization. The ability to tailor the magnetic properties of special steel makes it a valuable material for various industries, including telecommunications, energy, and electronics.

- Q: What are the different methods of surface ion nitriding for special steel?

- Surface ion nitriding of special steel can be achieved through various methods. These methods encompass: 1. Utilizing DC Plasma Nitriding: Employing direct current (DC) plasma to ionize nitrogen gas, a plasma atmosphere is created. By subjecting the special steel to the plasma chamber and applying high voltage, the ions are accelerated towards the steel's surface, resulting in nitriding. 2. Adopting RF Plasma Nitriding: Similar to DC plasma nitriding, RF (Radio Frequency) plasma nitriding employs a radio frequency power supply to generate plasma instead of direct current. This method allows for better control over the nitriding process and can accommodate more intricate geometries. 3. Employing Pulse Plasma Nitriding: By applying short pulses of high voltage to the steel surface, a plasma discharge is created. These pulses are repeated at regular intervals, enabling precise control over the nitriding process. Pulse plasma nitriding is commonly used for steels with sensitive properties that may be affected by prolonged exposure to high temperatures. 4. Combining Plasma Assisted Nitriding: This method combines plasma nitriding with other surface treatment techniques, such as physical vapor deposition (PVD) or chemical vapor deposition (CVD). Initially, the steel is coated with a thin layer of reactive material, followed by nitriding in a plasma atmosphere. This combination enhances the surface properties of the special steel, such as wear resistance or corrosion resistance. 5. Employing Glow Discharge Nitriding: This method involves placing the special steel in a chamber filled with a nitrogen-rich gas, such as ammonia. Applying high voltage creates a glow discharge, which ionizes the gas and generates nitrogen ions that diffuse into the steel's surface. Glow discharge nitriding is commonly employed for small parts or components with complex shapes. It is crucial to consider factors such as desired properties, steel geometry, and application-specific requirements when selecting the most suitable method for surface ion nitriding of special steel.

- Q: Can special steel be used in the beverage manufacturing industry?

- Yes, special steel can be used in the beverage manufacturing industry. Special steel, such as stainless steel, is commonly used in beverage processing equipment due to its corrosion resistance, hygienic properties, and durability. It is particularly suitable for manufacturing tanks, pipes, valves, and other components that come into contact with beverages, ensuring a high level of safety and maintaining the quality of the products.

- Q: How does special steel perform in terms of magnetic permeability?

- Special steel typically has a lower magnetic permeability compared to other materials, meaning it has a weaker response to magnetic fields.

- Q: How is special steel graded?

- Special steel is graded based on various factors such as its chemical composition, mechanical properties, and intended application. The grading system provides a standardized classification that helps in identifying and selecting the appropriate type of steel for specific purposes. One common method of grading special steel is through the use of alphanumeric codes. These codes typically consist of a combination of letters and numbers that represent specific characteristics of the steel. For example, the American Iron and Steel Institute (AISI) uses a four-digit numbering system to grade different types of steel alloys. The first digit indicates the main alloying element, such as carbon or manganese, while the subsequent digits provide additional details about the composition and properties of the steel. In addition to the alphanumeric codes, special steel can also be graded based on its mechanical properties. This involves testing the steel's strength, hardness, toughness, and other performance indicators. The results of these tests are then used to assign a specific grade to the steel, which helps users determine its suitability for certain applications. International standards organizations, such as ASTM International and the International Organization for Standardization (ISO), provide guidelines and specifications for the grading of special steel based on these mechanical properties. Furthermore, the intended application of the special steel also plays a significant role in its grading. Certain industries, such as aerospace or automotive, have specific requirements for the materials they use. Therefore, special steel intended for these sectors is graded based on its ability to meet those requirements, such as corrosion resistance, heat resistance, or wear resistance. Special steel grades can also be classified based on their ability to withstand extreme conditions or perform specific functions, such as tool steels for cutting or forming operations. Overall, the grading of special steel involves considering its chemical composition, mechanical properties, and intended application. By utilizing standardized grading systems and specifications, manufacturers, engineers, and other users can easily identify and select the most suitable type of special steel for their specific needs.

Send your message to us

Reinforcing Bars Hot Rolled Steel Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 110 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords