Hot Rolled Steel Piling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Some of the applications requiring steel sheet piling as stiff and flexible retaining wall are:

1. Waterfront structures

Steel sheet piling is suitable for offshore construction as it is designed to cater for heavy vertical loads and large bending moments with fast execution. Few types of retaining structures in waterfront structures are ship berthing area, wharf, breakwater and slipway.

2. Canalization

Steel sheet piling is used as the support, protection and beautification of river embankments. It can also function as flood protection wall during monsoon or high-tide season.

3. Basement

Steel sheet piling can be used for top down construction (permanent) or bottom up construction (temporary); both methods require minimal construction width offering significant time and cost savings. Steel sheet pile can also support vertical loads from the structure above.

4. Railway and Tunnel

As support structure for railway and tunnel construction, steel sheet piling helps to minimize excavation and disposal works, thus speed up the construction duration.

5. General Excavation

General excavation works involve temporary excavation for foundation construction and protection to underground structure, minimizing excavation volume and area.

6. Highway Construction

Most of the time, steel sheet piles act as retaining structure for excavation works. They can be installed easily and extracted anytime when the construction work is completed. The steel sheet piles can then be re-used and carried forward for later construction stages.

7. Bridge

Steel sheet piles can act as foundation and abutment of the bridge, requiring minimum space and construction time.

Types:

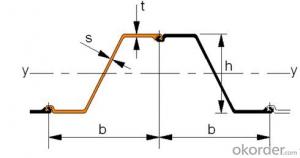

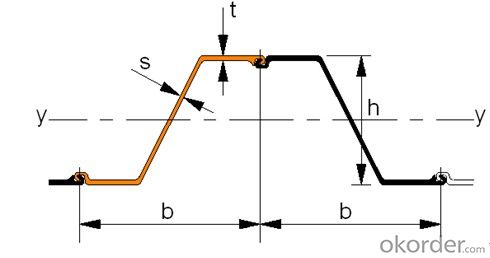

Z Section

Continuous form of the web and location of the interlock symmetrically on each side of the neutral axis provides positive influence on the section modulus on the Z section.

U Section

Symmetrical form of the single element made U section convenient for re-use or even applied as permanent solution.

OΩ Section

Innovative section allowing installation of sheet pile that is adjacent to existing structure and flexibility of changing profile widths with the wide range of omega sections.

- Q: What does "M" mean?

- M section steel: sectional shape steel like M.

- Q: Does the profile include H?

- In addition, the profiles include: profile steel, including gear ring, horseshoe steel, pole steel, foot plate, shallow channel, small channel steel, T-shaped steel, ball flat steel, send steel, hot-rolled, six angles, etc.. There are also rivets, steel, farm tools, steel, window frames, steel. Cold bending, cold drawn steel and so on.

- Q: What does "BH" mean?

- BH is welded to H just, and RH is hot rolled H steel.

- Q: Elastic modulus of section steel

- The elastic modulus of steel is 2.1 * 10^7N/cm L.

- Q: What kind of steel is used in steel columns?

- Section I and H of steel reinforced piles belong to the common section shapes in steel reinforced concrete piles. I and H type steel piles can be used in horizontal load and vertical load bearing. The steel pile has stronger penetration ability in many kinds of strata, moreover, its disturbance to stratum is slight, it is a kind of partly squeezed soil pile. If the distance between the driving pile and the center is smaller, the H steel pile can be used to replace other piles to prevent the ground fault caused by piling operation, such as lateral extrusion, uplift and so on.

- Q: What is special steel?

- Quality profilesHigh quality profiles is made of high quality steel processing profiles. Hot rolling (forging) quality profile, cold drawn (DIAL) quality profile and other varieties. Hot rolled (forging) quality profiles including carbon structural steel, carbon tool steel, alloy structural steel, spring steel, stainless steel, bearing steel, alloy tool steel, die steel, high-speed tool steel and other varieties. The cold (DIAL) quality profiles including carbon structural steel, carbon tool steel, alloy structural steel, spring steel, stainless steel, bearing steel, alloy tool steel, high-speed tool steel, free cutting steel, cold heading steel, S/5A and other varieties of.S/5A is a product used to make bombs, bullets.

- Q: Can the section steel butt joint in the end?

- Docking is usually available.If welding, it is mainly worried that the welding is not strong and the welding stress is too large. The wall thickness of the section steel is thin, and the butt welding itself is the most unreliable. So, in the joint lining board, fillet welded. Attention is paid to reducing stress in the process.Bolt connection also requires lining plate, pay attention to bolt size, quantity and spacing. To calculate whether thin-walled steel itself will be crushing, the solution is solder paste board, and bolt holes.In short, the principle is that the strength of the butt joint is not weaker than that of other parts, and there is no greater stress.

- Q: What are the common types of profiled steel?

- Section steel is divided into two types: simple section steel and complex section steel.Simple section steel: steel, wire rod, square steel, flat steel, six angle steel, triangular, elliptical steel, steel arch steel, etc..

- Q: How to distinguish cold formed section steel and hot rolled section steel?

- Hot rolled steel is a kind of steel with various geometrical cross section formed by heating billet. According to the different angles can be divided into flat steel, steel section, steel and I-shaped steel and hot-rolled L steel; steel according to the different section shape, divided into simple and complex section or section section and section three steel cycle:The characteristics of the simple section are the cross section, any point on the periphery as a tangent, generally not cross section, such as round steel, square steel, six angle steel, flat steel, triangular steel, arch steel and elliptical steel.Complex sections include angle steel, I-beam, channel steel, T steel, H steel, Z steel, rail, steel plate pile, window frame steel and other miscellaneous section steel;The periodic section shape and dimension along the length direction of the steel section changing periodically, such as rebar, axle and steel ploughshare.

Send your message to us

Hot Rolled Steel Piling

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords