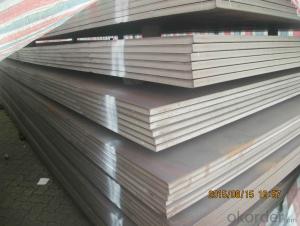

Hot Rolled Steel Plates Made in China WIth Good Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR SS400 CARBON STEEL SHEET

1.Thickness: 1-200mm

2.Width: 100-3000mm

3.Length: 1000-12000mm

4. Applications :mining machinery, environmental protection, engineering

5. Grade:SS400 A 36 Q195.Q235.Q345.SPCC.SPCH

6.Surface : Hot Rolled Cold Rolled Galvanized Steel

DESCRIPTION FOR CARBON STEEL PLATE

Product | carbon steel plate price per ton |

Place of origin | Tianjin,China mainland |

MOQ | 25 tons |

Thickness | 1mm-200mm |

Width | 1000mm-3000mm |

Length | 1000mm-2000mm |

Application | widely |

Standard | AISI,ASTM,BS,DIN,JIS,GB,etc |

Grade | A572,A573,A633,A678,A709,A710,G3101,G3136,etc |

Tpye | Steel plate |

Surfacing | Coated |

Productive Technology | Hot Rolled & Cold Rolled |

Price | FOB USD 500-900 per ton |

Port | TIANJIN,SHANGHAI |

Payment Terms | L/C,T/T,Western Union,MoneyGram |

Product Ability | 1000 tons per month |

Delivery | 10 days after deposit or according to customers' quantity |

Packing | standard seaworthy export packing or as the request of customers |

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC: 1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

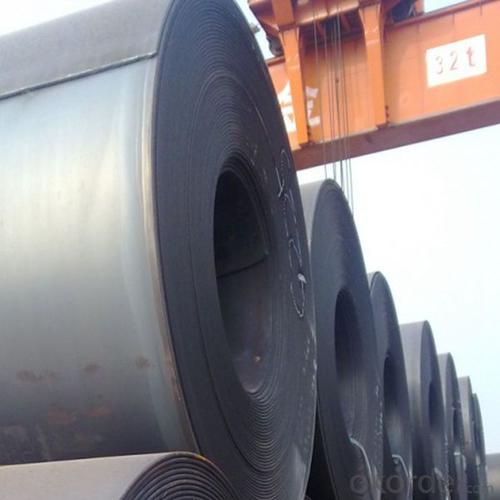

DETAILED PICTURES FOR STEEL COILS

FAQ:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: Are stainless steel sheets resistant to humidity?

- Stainless steel sheets possess resistance to humidity. The outstanding corrosion resistance properties of stainless steel are well-known, encompassing resistance to both moisture and humidity. This quality renders stainless steel sheets an appropriate material for a variety of applications in humid surroundings such as kitchens, bathrooms, and outdoor structures. The presence of chromium in stainless steel generates a protective layer of chromium oxide on the surface. This layer acts as a barrier against moisture, preventing its infiltration and subsequent corrosion. Moreover, stainless steel sheets find frequent use in industries such as food processing and pharmaceuticals, where cleanliness and hygiene are paramount. The sheets' resistance to humidity ensures their durability and longevity in such environments. All in all, stainless steel sheets serve as a dependable and long-lasting choice for humid conditions due to their innate moisture and corrosion resistance.

- Q: How do you prevent fingerprints and smudges on stainless steel sheets?

- To avoid fingerprints and smudges on stainless steel sheets, several effective techniques can be employed: 1. Opt for a microfiber cloth: Employ a soft microfiber cloth to gently wipe the stainless steel surface. Microfiber is gentle and will not cause any scratches or streaks. Avoid using rough materials such as paper towels or abrasive sponges. 2. Utilize a stainless steel cleaner: Invest in a high-quality stainless steel cleaner that is specifically designed to eliminate fingerprints and smudges. Adhere to the cleaner's instructions and evenly apply it to the surface using a cloth or sponge. Remove any excess cleaner with a clean cloth. 3. Apply baby oil or mineral oil: Dab a small amount of baby oil or mineral oil onto a cloth and delicately rub it over the stainless steel surface. This will create a thin protective layer that aids in preventing fingerprints and smudges from adhering to the metal. 4. Avoid direct contact with bare hands: Fingerprints and smudges often result from direct contact with hands. Endeavor to handle stainless steel sheets with clean, dry hands or wear gloves if necessary. This will minimize the transfer of oils and residue onto the surface. 5. Establish a regular cleaning routine: Implement a consistent cleaning regimen for your stainless steel sheets. Wipe them down with a microfiber cloth or stainless steel cleaner at least once a week, or more frequently in high-traffic areas. This will hinder the accumulation of oils and grime, thereby reducing the likelihood of fingerprints and smudges. By adhering to these methods, you can effectively thwart the occurrence of fingerprints and smudges on stainless steel sheets, preserving their cleanliness and shine for an extended duration.

- Q: Stainless steel plate glued to tiles, what glue?

- For the high temperature does not exceed 200 degrees, and is transparent, can be used to connect the WB66 type of glue glue, the glue adhesive glue is professional, high temperature resistant and can be used in metal adhesive bonding, high speed, high strength, good toughness, long shelf life, suitable for viscose between ceramic and metal the.

- Q: Which is better, stainless steel plate kitchen?

- Classification according to functional characteristics can be divided into non-magnetic stainless steel, easy to cut stainless steel, low temperature stainless steel, high strength stainless steel and so on. Because the stainless steel material with excellent corrosion resistance, formability, and compatibility in a wide temperature range, strong toughness characteristics, so get widely used in heavy industry, light industry, supplies industry and construction decoration industry.

- Q: Are stainless steel sheets suitable for cryogenic applications?

- Yes, stainless steel sheets are suitable for cryogenic applications. Stainless steel is known for its excellent mechanical properties, including high strength and toughness, which make it suitable for low-temperature environments. Additionally, stainless steel has good corrosion resistance, which is crucial when exposed to cryogenic temperatures. It maintains its mechanical properties and does not become brittle at ultra-low temperatures. Therefore, stainless steel sheets are commonly used in cryogenic applications such as storage tanks, pipelines, and equipment for liquefied natural gas (LNG), liquid nitrogen, and other cryogenic fluids.

- Q: Can stainless steel sheets be used for bridge construction?

- Yes, stainless steel sheets can be used for bridge construction due to their excellent strength, durability, and corrosion resistance properties.

- Q: What are the advantages of using stainless steel sheets in the medical industry?

- There are several advantages of using stainless steel sheets in the medical industry. Firstly, stainless steel is highly resistant to corrosion, making it a durable and long-lasting material for medical equipment and instruments. This resistance to corrosion is crucial in maintaining sterile conditions and preventing the growth of bacteria or other harmful microorganisms. Additionally, stainless steel is easy to clean and sanitize, reducing the risk of cross-contamination. It is also non-reactive, meaning it does not release any harmful substances or chemicals into the medical environment. Lastly, stainless steel has a high strength-to-weight ratio, making it ideal for constructing lightweight yet sturdy medical devices. Overall, the use of stainless steel sheets in the medical industry ensures safety, hygiene, and reliability.

- Q: What is the minimum thickness of stainless steel sheets available?

- The minimum thickness of stainless steel sheets offered may differ based on the manufacturer and the particular grade of stainless steel employed. Typically, the thinnest stainless steel sheets offered range from 0.4mm to 0.5mm. Nevertheless, it is worth mentioning that certain manufacturers might provide thinner sheets, like 0.3mm, although these may be more specialized or not as readily accessible. If you have a specific thickness requirement for your project, it is advisable to seek guidance from stainless steel suppliers or manufacturers to ascertain the available choices.

- Q: How do stainless steel sheets compare to other materials, such as aluminum or carbon steel?

- Stainless steel sheets offer distinct advantages when compared to other materials like aluminum or carbon steel. They have superior corrosion resistance, making them ideal for applications in harsh environments or industries like food processing. Stainless steel sheets also possess high heat resistance, strength, and durability, making them suitable for various structural and industrial purposes. While aluminum is lightweight and has good conductivity, it lacks the same level of strength and corrosion resistance. Carbon steel, on the other hand, is strong but more susceptible to corrosion. Overall, stainless steel sheets provide a balance of strength, durability, and corrosion resistance, making them a preferred choice in many industries.

- Q: What are the different types of stainless steel sheet edge treatments available?

- Various edge treatments are available for stainless steel sheets, each offering distinct advantages and aesthetic options. 1. The mill edge treatment is the most commonly used, where the stainless steel sheet is produced with an unfinished, straight edge. It is cost-effective and suitable for applications that prioritize functionality over appearance. 2. The slit edge treatment involves cutting the stainless steel sheet to the desired width, resulting in a smooth edge. Slit edge sheets are commonly used in industries like food processing and pharmaceuticals, where a clean, burr-free finish is necessary. 3. The deburred edge treatment focuses on removing any burrs or sharp edges from the stainless steel sheet, leaving a smooth and safe edge. It is often employed in architectural or automotive applications where safety is a concern. 4. The rolled edge treatment involves bending the stainless steel sheet to create a rounded edge. This treatment is popular in applications where safety and aesthetics are important, such as kitchen appliances or decorative pieces. 5. The beveled edge treatment refers to cutting the stainless steel sheet at an angle, creating a diagonal edge. Beveled edges are commonly used in architectural applications to achieve a smooth transition between different materials or enhance the overall design. These examples illustrate the range of stainless steel sheet edge treatments available. The choice of treatment depends on specific application requirements, including functionality, safety, and aesthetics.

Send your message to us

Hot Rolled Steel Plates Made in China WIth Good Quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords