Hot Rolled Steel Plates Steel Sheets made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

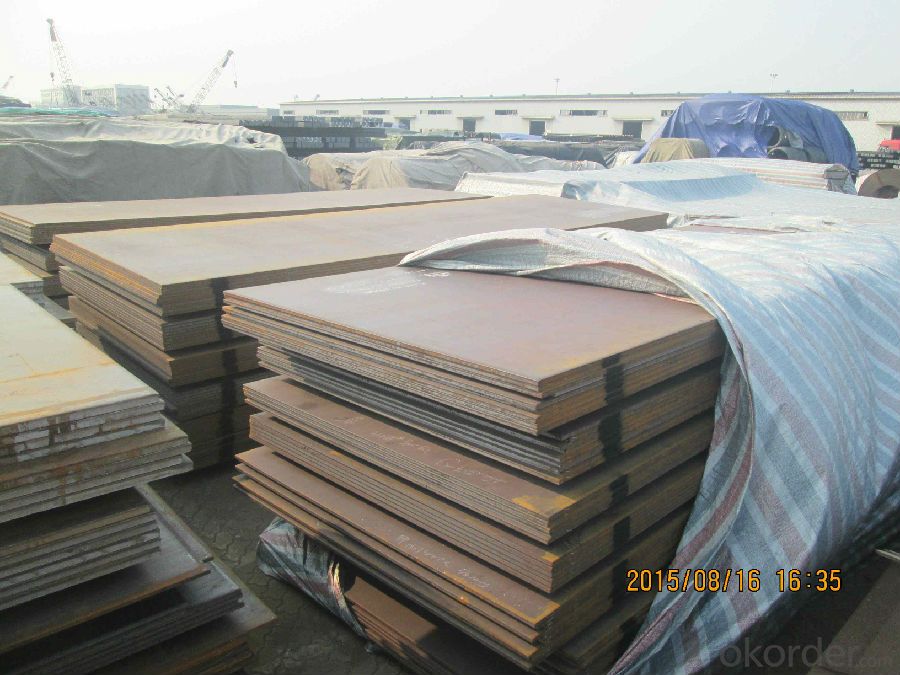

OKorder is offering Hot Rolled Steel Plates Steel Sheets made in China at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Plates Steel Sheets made in China are ideal for structural applications and are widely used in construction,machinery manufacturing, container manufacturing, shipbuilding, bridge construction. Can also be used to manufacture a variety of containers, the furnace shell, furnace plate, bridge and vehicle static steel plate, low alloy steel plate,shipbuilding plate, boiler plate, pressure vessel plate, pattern plate, tractor parts, automobile frame steel plate and welding components.

Product Advantages:

OKorder's Hot Rolled Steel Plates Steel Sheets made in China are durable, strong, and wide variety of sizes.

Main Product Features:

•Hot Rolled & Annealing

•Good Quality & Fast Delivery

•Competitive Price & Nice Service

Product Specifications:

Thickness | 2-100mm |

Width | 1250mm,1500mm,1800mm,2000mm.,2500mm or as required |

Length | 2000-12000mm |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | A36,SS400,SPCC,SPHC, Q195, Q 235,Q345 |

Tehnique | Hot rolled;cold rolled |

Payment | TT ,L/C |

Packing | Standard seaworthy packing or as required |

Market | Mild east, North/South America, Europe, Asia,Africa etc |

Certificate | BV,SGS,MTC |

Delivery time | Within 7-10 days |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: What are the different sheet metal finishing techniques for steel sheets?

- Some of the different sheet metal finishing techniques for steel sheets include deburring, grinding, polishing, sanding, and painting.

- Q: What are the different types of steel sheet alloys?

- There are several different types of steel sheet alloys, each with its own unique properties and applications. Some of the most common steel sheet alloys include: 1. Carbon Steel: This is the most basic type of steel and contains mainly iron and carbon. It is widely used in construction, automotive, and manufacturing industries due to its strength and affordability. 2. Stainless Steel: Known for its corrosion resistance, stainless steel is made by adding chromium and other alloying elements to carbon steel. It is commonly used in applications where hygiene and durability are important, such as kitchen appliances, medical equipment, and architectural structures. 3. Galvanized Steel: This type of steel is coated with a layer of zinc to protect it from corrosion. Galvanized steel sheets are often used in outdoor applications, such as roofing, fencing, and automotive parts. 4. Alloy Steel: Alloy steel sheets are made by adding various alloying elements, such as nickel, chromium, and molybdenum, to carbon steel. These alloys enhance the strength, hardness, and wear resistance of the steel, making it suitable for applications in industries like aerospace, automotive, and machinery. 5. Tool Steel: Tool steel is specifically designed for the production of tools and dies. It is characterized by its high hardness, resistance to deformation, and ability to retain sharp edges. Tool steel sheets are commonly used in the manufacturing of cutting tools, drills, and molds. 6. Electrical Steel: This type of steel has been specially processed to have low magnetic losses and high electrical conductivity. Electrical steel sheets are used in the production of transformers, electric motors, and generators. These are just a few examples of the different types of steel sheet alloys available. Depending on the specific requirements of a project or application, engineers can choose the appropriate alloy to achieve the desired properties and performance.

- Q: Can steel sheets be used for HVAC ductwork?

- Yes, steel sheets can be used for HVAC ductwork. Steel is a common material used in HVAC ductwork due to its durability, strength, and fire resistance properties. Steel sheets can be fabricated and shaped into ducts, providing a reliable and long-lasting solution for HVAC systems.

- Q: What are the different surface treatments for stainless steel sheets?

- Some of the different surface treatments for stainless steel sheets include brushing, mirror polishing, bead blasting, etching, and electroplating. Each treatment provides a different aesthetic appearance and can also enhance the corrosion resistance and durability of the stainless steel.

- Q: Can steel sheets be used in the medical industry?

- Yes, steel sheets can be used in the medical industry. Steel is a strong and durable material that can be easily sterilized, making it suitable for various applications in healthcare settings. Steel sheets are commonly used in the construction of medical equipment, such as surgical tables, medical carts, and storage cabinets. They provide stability and support for medical devices and instruments, ensuring quality and safety during medical procedures. Additionally, steel sheets can be used in the fabrication of medical furniture, such as examination tables and hospital beds, due to their strength and resistance to wear and tear. Overall, steel sheets are a reliable and versatile material that can effectively meet the demanding requirements of the medical industry.

- Q: What is the average lead time for ordering steel sheets?

- The average lead time for ordering steel sheets can vary depending on various factors such as the supplier, quantity required, customization needs, and current market conditions. However, on average, the lead time for ordering steel sheets typically ranges from a few days to several weeks. If the steel sheets are readily available in stock with the supplier, the lead time could be as short as a few days or even less, allowing for quick fulfillment of the order. However, if the steel sheets need to be sourced from a specific mill or manufacturer, the lead time can be longer. This is especially true if the order requires custom specifications, such as specific dimensions, finishes, or grades of steel. Other factors that can affect lead time include the supplier's production capacity and workload, transportation and logistics considerations, and any potential delays caused by unforeseen circumstances such as natural disasters or labor disputes. It is crucial to communicate with the supplier or manufacturer to get accurate lead time estimates for ordering steel sheets. They will be able to provide specific information based on their production capabilities and current circumstances. Additionally, it is always advisable to plan ahead and allow for some buffer time to account for any potential delays or unforeseen challenges that may arise during the ordering process.

- Q: Can steel sheets be used for magnetic shielding?

- Yes, steel sheets can be used for magnetic shielding as they have high magnetic permeability, meaning they can redirect and absorb magnetic fields, providing effective shielding against magnetic interference.

- Q: Are the steel sheets resistant to impact or bending?

- Yes, steel sheets are generally resistant to both impact and bending due to their high strength and rigidity.

- Q: What is a steel sheet?

- A steel sheet is a flat and thin piece of metal made from steel, commonly used in construction, manufacturing, and various industrial applications.

- Q: Is color steel plate the same as color steel tile?

- Tile color steel tile is used for color coated steel plate, pressure plate and the roller of cold bending into various wave types, it is suitable for industrial and civil buildings, warehouses, special buildings, large-span steel structure house roof, walls and wall decoration, has the characteristics of light weight, high strength, color rich, convenient construction, affluence earthquake, fire, rain, long service life, maintenance free, have been widely applied.

Send your message to us

Hot Rolled Steel Plates Steel Sheets made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords