Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China

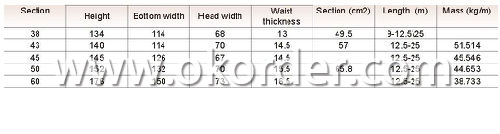

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Applications of Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China

Heavy rail is suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.

Tunnel way, curve way, railway, subway, transportation track, express, etc.

Package & Delivery of Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, size, length, grade, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ

Q1: Why buy Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in Chinafrom OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 20 to 30 workdays.

- Q: What is the impact of extreme temperatures on steel rail performance?

- Extreme temperatures can have a significant impact on steel rail performance. In high temperatures, steel rails can expand, leading to buckling and misalignment, posing safety risks for trains. Conversely, in extremely cold temperatures, steel rails contract, which can cause cracking and brittleness, reducing their structural integrity. These temperature-induced changes can result in increased maintenance costs, service disruptions, and potential safety hazards for railway operations.

- Q: What are the maintenance costs associated with steel rails?

- The maintenance costs associated with steel rails include regular inspections for wear and tear, cleaning to remove debris and prevent corrosion, lubrication to minimize friction, and occasional repairs or replacements of damaged sections.

- Q: What are the safety measures for working on electrified steel rail tracks?

- Working on electrified steel rail tracks can be potentially dangerous, so it is crucial to follow safety measures to ensure the well-being of workers. Here are some important safety measures to consider: 1. Adequate Training: Workers must receive proper training on working with electrified rail tracks. This should include understanding the electrical hazards associated with the tracks, emergency procedures, and how to safely handle tools and equipment. 2. Personal Protective Equipment (PPE): Workers must always wear the appropriate PPE, such as insulated gloves, safety glasses, hard hats, and flame-resistant clothing. Insulated tools should also be used to minimize the risk of electrical shock. 3. Lockout/Tagout (LOTO): Before starting any work, the electrical power supply to the tracks should be properly locked out or tagged out to prevent accidental energization. Only authorized personnel should have access to the lockout/tagout devices. 4. Risk Assessment: Conduct a thorough risk assessment before starting work on electrified rail tracks. Identify potential hazards, such as live wires, faulty electrical equipment, or overhead lines, and implement control measures to mitigate these risks. 5. Communication: Maintain clear communication with other workers, signaling personnel, and train operators. Ensure that all parties are aware of the work being carried out and any potential hazards that may arise. 6. Safe Work Zones: Establish clear boundaries and safe work zones to prevent unauthorized access to the electrified tracks. Use barriers, signage, and warning lights to clearly indicate the presence of electrical hazards. 7. Proper Tools and Equipment: Use only tools and equipment specifically designed for working on electrified rail tracks. Insulated tools and equipment should be regularly inspected and maintained to ensure their integrity. 8. Proper Ladder Usage: When working at heights near electrified tracks, ensure that ladders are made of non-conductive materials and are positioned away from live wires or overhead lines. Workers should avoid leaning or touching any electrical components while on the ladder. 9. Emergency Preparedness: Have a well-defined emergency response plan in place in case of accidents or incidents. Train workers on emergency procedures, including evacuation routes, first aid, and how to respond to electrical shock or burns. 10. Regular Inspections and Maintenance: Regularly inspect the electrified rail tracks, electrical equipment, and tools to identify potential issues or defects. Any faulty equipment or infrastructure should be immediately reported and repaired to prevent accidents. It is crucial to prioritize safety when working on electrified steel rail tracks. By following these safety measures, workers can minimize the risks associated with electrical hazards and ensure a safe working environment.

- Q: Can steel rails be used in coastal areas with saltwater exposure?

- In coastal areas with saltwater exposure, steel rails can be utilized, albeit with the necessity of specialized protection and maintenance in order to avert corrosion. The presence of salt in the atmosphere and water can expedite the corrosion procedure, ultimately causing the deterioration of the steel rails. To counteract this, coastal railway systems frequently employ diverse protective techniques including the application of anti-corrosion coatings, the utilization of stainless steel or corrosion-resistant alloys, and the implementation of regular maintenance and inspection schedules. These measures effectively alleviate the adverse effects of saltwater exposure and prolong the lifespan of steel rails in coastal regions.

- Q: Can steel rails be used for magnetic levitation (maglev) trains?

- Maglev trains cannot utilize steel rails as they lack the necessary magnetic properties. Steel is a ferromagnetic material, meaning it can be magnetized but loses its magnetism once the external magnetic field is removed. Strong and stable magnetic fields are essential for maglev trains to achieve levitation and propulsion, which cannot be achieved with steel rails. To enable maglev technology, alternative materials or systems must be used. One common approach involves the use of superconducting magnets, which generate intense magnetic fields without the need for a continuous power supply. These magnets are mounted on the train and interact with the guideway's electromagnets to achieve levitation and propulsion. In conclusion, steel rails are incompatible with maglev train systems due to their insufficient magnetic properties. Specialized technologies, such as superconducting magnets, are necessary to enable the magnetic levitation and propulsion relied upon by maglev trains.

- Q: Are steel rails suitable for high-speed train operations?

- Steel rails are indeed suitable for high-speed train operations. They have been utilized in railway systems worldwide for many years, including those specifically designed for high-speed trains. Steel is a robust and enduring material that is capable of withstanding the immense pressures and fast speeds of modern trains. Furthermore, steel rails possess exceptional track stability and are capable of enduring extreme weather conditions, thus rendering them suitable for high-speed train operations in various environments. Additionally, steel rails offer a smooth and dependable surface for trains to traverse, resulting in reduced vibrations and ensuring a comfortable journey for passengers. All in all, steel rails have demonstrated themselves to be a dependable and efficient choice for high-speed train operations.

- Q: Are steel rails compatible with different train types?

- Yes, steel rails are compatible with different train types. Steel rails are designed to be universally compatible with various types of trains, including locomotives, passenger trains, freight trains, and high-speed trains. The standardized size, shape, and strength of steel rails allow them to be used efficiently and safely by different train types on railway tracks.

- Q: What is the process of reconditioning old steel rails?

- The process of reconditioning old steel rails involves several steps. First, the rails are inspected to identify any defects or damages. Then, the damaged sections are cut out and removed. The remaining rail is cleaned thoroughly to remove any rust, dirt, or debris. Next, the rail is heat-treated to restore its strength and durability. If necessary, the rail can be straightened or bent to meet specific requirements. Finally, the rail is coated with a protective finish to prevent corrosion and enhance its longevity. Overall, reconditioning old steel rails aims to restore them to their original quality and extend their lifespan.

- Q: How are steel rails protected against fire hazards?

- Steel rails are protected against fire hazards through a combination of preventative measures and fire suppression systems. Some common methods include the installation of fire-resistant materials such as fire-resistant coatings or fireproof insulation around the rails. Additionally, fire detection systems are often put in place to detect any potential fire incidents early on, allowing for prompt response and extinguishment. Regular maintenance and inspections also play a crucial role in ensuring the integrity of steel rails, minimizing any fire risks.

- Q: What's the gauge for the high speed rail?

- At present, although most countries use 1435 mm wide gauge, there are still more than 30 different gauges. From narrow to wide, 610 mm, 762 mm, 891 mm, 1000 mm, 1067 mm, 1372 mm, 2141 mm, 1435 mm, 1524 mm, 1880 mm, mm mm, etc..

Send your message to us

Hot Rolled Mild Heavy Steel Rials for Minas 50Mn, U71Mn Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords