Steel Rail bar

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 1000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

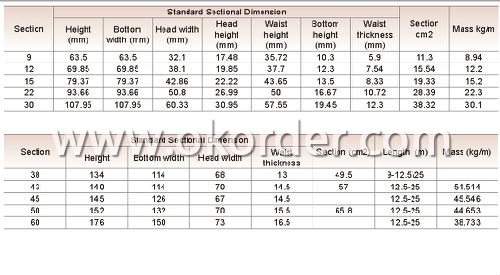

Specifications of Steel Rail Bar

Light Rail: 9kg, 12kg, 15kg, 22kg, 30kg

Heavy Rail: 38kg, 43kg, 45kg, 50kg, 60kg

Material Specifications:

Light Rail: GB 11264-89 Q235B, 55Q

Heavy Rail: GB 2585-81 50Mn, U71Mn

Length: 6M, 10M, 12M, 12.5M, 24M or as the requirements of the client

Applications of Steel Rail Bar

The Steel Rail Bar will be widely used to the railway, subway, transportation track, express, curve way, tunnel way and so on.

Package & Delivery of Steel Rail Bar

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

Production flow of Steel Rail Bar

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Are steel rails more durable than other types of rails?

- In general, steel rails are regarded as more durable than rails made from other materials. The strength and durability of steel are well-known, which makes it an ideal choice for constructing railway tracks. Steel rails can endure heavy loads, harsh weather conditions, and frequent usage without experiencing significant wear and tear. Furthermore, steel rails have a longer lifespan when compared to alternative materials like wood or concrete. They need less maintenance and are less prone to damage from factors such as corrosion or impact. All in all, the durability of steel rails makes them the preferred option for railway infrastructure.

- Q: How do steel rails handle frequent train stops and starts?

- Steel rails are designed to handle frequent train stops and starts effectively. The properties of steel, such as its strength and durability, make it an ideal material for railway tracks. When a train stops or starts, the steel rails are subjected to significant forces, including the weight of the train and the dynamic forces generated during acceleration or deceleration. Steel rails are able to handle these forces due to their high tensile strength, which allows them to withstand the weight of the train and distribute the load evenly along the track. Additionally, steel is a resilient material, meaning it can deform under stress and return to its original shape once the stress is removed. This property allows the rails to absorb the impact and vibrations caused by train stops and starts, minimizing the risk of damage or deformation. Furthermore, steel rails are designed to have a smooth and continuous surface, reducing the friction between the wheels of the train and the tracks. This helps in the smooth transition of the train during stops and starts, minimizing wear and tear on the rails. Additionally, steel rails are often treated with various coatings or finishes to provide protection against corrosion, further enhancing their durability and ability to handle frequent train stops and starts. In summary, steel rails are specifically engineered to handle the demands of frequent train stops and starts. Their strength, resilience, and smooth surface contribute to their ability to withstand the forces generated during these operations while minimizing wear and tear. This ensures the longevity and safety of railway tracks, providing a reliable infrastructure for efficient train operations.

- Q: How do steel rails contribute to reducing train operating costs?

- Steel rails contribute to reducing train operating costs in several ways: 1. Durability: Steel rails are highly durable and can withstand heavy loads and constant use. This reduces the need for frequent repairs or replacements, resulting in lower maintenance costs over time. 2. Enhanced safety: Steel rails provide a stable and secure track structure, reducing the risk of derailments and accidents. This improves safety and reduces the costs associated with accidents, such as damage to the train and infrastructure, legal expenses, and potential compensation claims. 3. Fuel efficiency: Steel rails offer a smooth and reliable surface for train wheels to roll on, minimizing rolling resistance. This allows trains to maintain higher speeds with lower energy consumption, resulting in reduced fuel costs and improved operational efficiency. 4. Longevity: Steel rails have a long lifespan, often exceeding 30 years with proper maintenance. This longevity reduces the need for frequent replacements, saving both time and money. 5. Low maintenance requirements: Steel rails require relatively low maintenance compared to other track materials. They are resistant to weather conditions, such as extreme temperatures and corrosion, reducing the need for constant inspections and repairs. This helps to lower maintenance costs and allows for more efficient use of maintenance resources. 6. Improved reliability: Steel rails provide a consistent and predictable track surface, minimizing disruptions and delays caused by track defects. This improves the reliability of train operations, reducing associated costs such as penalties for late deliveries, customer dissatisfaction, and the need for alternative transportation arrangements. Overall, the use of steel rails contributes to reducing train operating costs by providing a durable, safe, fuel-efficient, and low-maintenance track infrastructure. This allows for more efficient and reliable train operations, ultimately resulting in cost savings for railway companies.

- Q: How do steel rails affect train energy consumption?

- The impact of steel rails on train energy consumption is significant. Firstly, the smooth and sturdy surface provided by steel rails reduces friction between the train wheels and the tracks. This, in turn, minimizes energy losses during train movement and facilitates efficient energy transfer from the locomotive to the wheels. Moreover, steel rails possess high strength and durability, allowing trains to maintain their speed and momentum without excessive energy loss. The rigidity of these rails also ensures straight and properly aligned tracks, reducing the need for constant adjustments and minimizing energy consumption. Additionally, the weight-bearing capacity of steel rails enables trains to carry heavier loads, resulting in increased energy efficiency. By transporting more goods in a single trip, trains can reduce the number of journeys required, ultimately saving energy and reducing emissions. In conclusion, steel rails play a vital role in minimizing energy consumption in train operations. They reduce friction, provide stability, and facilitate efficient transportation of goods, all of which contribute to a more energy-efficient and sustainable railway system.

- Q: Can steel rails be used for port railways?

- Yes, steel rails can be used for port railways. Steel rails are commonly used in railway tracks due to their strength, durability, and ability to handle heavy loads. These qualities make them suitable for port railways as well, where there is a need to transport large quantities of goods and materials efficiently.

- Q: What are the safety measures in place for steel rail construction sites?

- Safety measures in place for steel rail construction sites typically include: 1. Personal Protective Equipment (PPE): All workers are required to wear appropriate PPE such as hard hats, safety glasses, high-visibility clothing, steel-toe boots, and gloves to protect themselves from potential hazards. 2. Fall protection: Fall protection systems like harnesses, safety nets, and guardrails are implemented to prevent workers from falling while working at heights. 3. Traffic control: Steel rail construction sites often involve heavy machinery and vehicles. Proper traffic control measures are implemented to ensure the safety of both workers and the general public, including the use of barricades, signs, and flaggers. 4. Equipment safety: Regular inspections and maintenance of equipment and machinery are conducted to ensure they are in proper working condition. Workers are trained to use equipment safely and follow operating procedures. 5. Hazard communication: Clear signage is posted to identify potential hazards and communicate safety procedures to workers. Material Safety Data Sheets (MSDS) are provided for any hazardous materials present on site. 6. Training and education: Workers receive comprehensive training on safety protocols, emergency procedures, and proper use of equipment. Regular safety meetings and toolbox talks are conducted to keep workers informed and updated. 7. Emergency response: Adequate first aid kits, fire extinguishers, and emergency response plans are in place. Workers are trained to respond to emergencies effectively and quickly. 8. Site security: Access to the construction site is restricted to authorized personnel only. Fencing, gates, and security measures are implemented to prevent unauthorized entry and ensure the safety of workers. These safety measures are put in place to minimize accidents, injuries, and ensure a safe working environment for everyone involved in steel rail construction projects.

- Q: Can steel rails be used in railway tunnels?

- Absolutely! Railway tunnels can indeed utilize steel rails. In fact, steel rails are widely employed in railway tunnels across the globe. The reason behind this preference lies in steel's exceptional attributes, namely its robustness, longevity, and ability to endure wear and tear. Steel rails have the capacity to withstand substantial loads, maintain stability, and facilitate the seamless passage of trains within tunnels. Moreover, steel rails offer an added advantage of being economically advantageous compared to alternative materials, rendering them a highly favored option in tunnel construction.

- Q: What are the environmental benefits of using steel rails over other materials?

- There are several environmental benefits associated with using steel rails over other materials. Firstly, steel is a highly durable material, which means that steel rails have a longer lifespan compared to other materials like wood or concrete. This reduces the need for frequent replacement and minimizes waste generation. Furthermore, steel is a recyclable material, and the process of recycling steel requires less energy and resources compared to producing new steel. Recycling steel rails reduces the demand for raw materials and decreases the environmental impact associated with mining and extraction. Additionally, steel rails have a lower carbon footprint compared to other materials. Steel production emits fewer greenhouse gases compared to materials like concrete. This contributes to mitigating climate change and reducing air pollution. Overall, the use of steel rails offers significant environmental benefits by reducing waste generation, promoting recycling, and minimizing greenhouse gas emissions.

- Q: How are steel rails installed and replaced?

- Steel rails are installed by first preparing the track bed by leveling and aligning it. Next, the rails are laid on the track bed and secured with fasteners such as clips or spikes. The rails are then connected with joint bars to ensure a continuous track. During replacement, the old rails are removed by disconnecting them from the joint bars and fasteners. New rails are then placed in the same manner as installation, ensuring proper alignment and secure fastening.

- Q: How do steel rails handle the effects of heavy braking and acceleration?

- Steel rails are designed to handle the effects of heavy braking and acceleration effectively. The high-strength and durability of steel enables it to withstand the immense forces generated during these operations. Additionally, steel's resistance to wear and deformation ensures that the rails can maintain their shape and integrity even under repeated heavy braking and acceleration, making them a reliable choice for rail transportation systems.

1. Manufacturer Overview

| Location | Anshan, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 650 Million |

| Main Markets | Middle East; Asia; South America; Africa; Oceania |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 50% - 70% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Steel Rail bar

- Loading Port:

- Tianjin Port, China

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 1000MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords