Hot Rolled Light Steel Rail with High Quality 55Q

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Light Steel Rail with High Quality 55Q at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

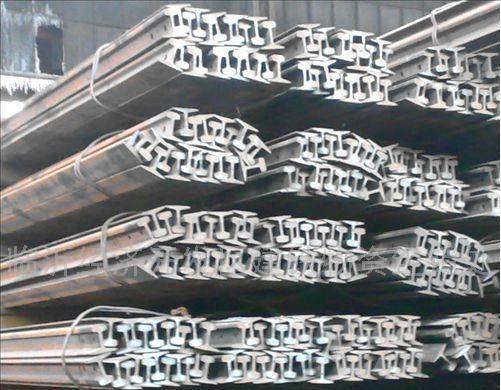

Hot Rolled Light Steel Rail with High Quality 55Q is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line.

Product Advantages:

OKorder's Hot Rolled Light Steel Rail with High Quality 55Q are durable, strong, and with competitive price

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

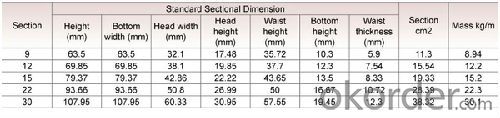

Product Specifications:

Manufacture: Hot rolled

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 25m, as per customer request

Packaging: Export packing, nude packing, bundled

Production Standard: GB 11264-89, GB2585-81, AREMA2008, JIS, DIN536, EN13674-1-2003, etc.

Sizes: 9kg-60kg

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4:What is the package

A4: Standard seaworthy packing or as customer required; all goods are packed in bundle with steel strips and shipped by break bulk vessel or container

Images:

.

- Q: Can steel rails be used in high-speed railway switches?

- Yes, steel rails can be used in high-speed railway switches. Steel rails are commonly used in railway tracks due to their strength, durability, and resistance to wear and tear. High-speed railway switches, also known as turnouts or points, are designed to allow trains to switch from one track to another. These switches are subjected to intense forces and high speeds, so they require robust materials. Steel rails have the necessary properties to withstand these conditions, making them suitable for high-speed railway switches. Additionally, steel rails can be manufactured with precise dimensions and smooth surfaces, ensuring a safe and efficient operation of the switches.

- Q: How are steel rails protected against animal intrusions?

- Steel rails are protected against animal intrusions through various methods. One common method is the installation of fencing along the railway tracks. This helps to prevent animals from accessing the tracks and potentially causing accidents. The fencing is typically made of strong materials such as steel or wire mesh to ensure durability and effectiveness. Additionally, some railway companies use deterrents such as motion-activated lights or noise devices to scare away animals. These devices are strategically placed along the tracks and are triggered when an animal approaches, creating a deterrent effect and preventing them from entering the railway area. Another approach is the use of specialized animal crossings or underpasses. These are designed to provide a safe passage for animals to cross underneath or over the railway tracks, minimizing the risk of collisions or interference with trains. Furthermore, regular maintenance and vegetation control along the tracks are crucial in preventing animal intrusions. By keeping the area clear of bushes, overgrown vegetation, and fallen trees, animals are less likely to be attracted to the tracks or find shelter there. Overall, protecting steel rails against animal intrusions requires a combination of physical barriers, deterrents, and proper maintenance. These measures aim to ensure the safety of both the animals and the railway operations, reducing the risks of accidents and disruptions caused by animal intrusions.

- Q: How do steel rails handle dynamic train loads?

- Steel rails are designed to handle dynamic train loads effectively due to their strength and durability. They are capable of distributing the weight and impact of moving trains evenly, ensuring stability and preventing excessive deformation or damage to the tracks. The high tensile strength of steel allows rails to resist bending, while their flexibility helps absorb vibrations and shocks, reducing the impact on the train and increasing passenger comfort. Additionally, proper maintenance and inspection of steel rails play a crucial role in ensuring their ability to handle dynamic train loads efficiently.

- Q: How do steel rails contribute to the reduction of accidents in rail transportation?

- Steel rails contribute to the reduction of accidents in rail transportation by providing a strong and durable track structure that allows for smooth and stable train movement. The use of steel rails ensures that trains can travel at high speeds without derailing or losing control, minimizing the risk of accidents. Additionally, steel rails are designed to withstand heavy loads and extreme weather conditions, preventing track failures that could lead to accidents. Regular maintenance and inspections of steel rails further enhance safety by identifying potential issues before they can escalate into accidents.

- Q: Can steel rails be used in areas with high humidity?

- Steel rails can indeed be utilized in regions with elevated humidity levels. Thanks to its exceptional durability and resistance to corrosion, steel proves to be an optimal material for diverse environments, even ones characterized by high humidity. Nevertheless, it is crucial to undertake appropriate maintenance and protective measures to avert rust and corrosion in the long run. Regular cleaning, the application of protective coatings, and diligent inspection for any indications of harm or deterioration play a vital role in guaranteeing the prolonged lifespan and secure functioning of steel rails in humid areas.

- Q: How are steel rails protected against soil erosion?

- Various measures are taken to protect steel rails from soil erosion. One commonly used method involves installing ballast, which consists of crushed stones or gravel placed beneath and around the rails. The ballast acts as a drainage system, allowing water to flow freely and preventing water accumulation near the rails. This minimizes the risk of soil erosion caused by water runoff. In addition, retaining walls and embankments are often constructed alongside railway tracks to prevent soil erosion. These structures provide stability to the surrounding soil, preventing it from being washed away by rainwater or other external forces. Retaining walls can be made of erosion-resistant materials such as concrete or stone. Another technique used to protect steel rails from soil erosion is the implementation of erosion control measures like slope stabilization and vegetation cover. Slope stabilization involves using erosion control blankets or geotextiles on the slopes next to the tracks to prevent soil displacement. Vegetation cover involves planting grass or other types of plants along the railway corridor. The roots of these plants bind the soil, reducing the risk of erosion. Regular maintenance and inspections are also crucial in preventing soil erosion. Rail operators regularly inspect the tracks to identify signs of erosion or instability. If any issues are detected, appropriate measures are promptly taken to repair or reinforce the affected areas. Overall, a combination of ballast, retaining walls, erosion control measures, and regular maintenance ensures that steel rails are adequately protected against soil erosion. These measures contribute to the longevity and safety of railway infrastructure.

- Q: How are steel rails manufactured to meet specific standards?

- Steel rails are manufactured to meet specific standards through a rigorous process that involves carefully selected raw materials, precise manufacturing techniques, and stringent quality control measures. The production begins with the selection of high-quality steel, which is then heated and rolled to form the desired shape of the rail. The rails are further processed through various stages such as cooling, straightening, and cutting to achieve the required dimensions and mechanical properties. Additionally, strict quality checks are conducted at each step to ensure the rails meet the specific standards for strength, durability, and dimensional accuracy.

- Q: How do steel rails handle high-speed train braking forces?

- Steel rails are designed to handle high-speed train braking forces by incorporating several key features. Firstly, steel rails are made from high-strength materials such as carbon steel or alloy steel, which have excellent mechanical properties and can withstand high levels of stress and pressure. This ensures that the rails remain intact and do not deform or break under the intense forces exerted by the train's brakes. Additionally, steel rails are specifically engineered to have a certain level of elasticity. This elasticity allows the rails to absorb and distribute the braking forces evenly along their length, preventing concentrated stress points that could lead to damage or failure. The elasticity also helps to reduce vibrations and noise generated during braking, enhancing the overall safety and comfort of the train ride. Furthermore, steel rails are carefully designed and maintained to have a smooth and even surface. This minimizes the risk of wheel-rail contact issues, such as wheel sliding or wheel flats, which can occur during high-speed braking. The smooth surface helps to ensure efficient and consistent braking performance, allowing for safe deceleration of the train. In addition to the physical properties of the steel rails, a range of engineering practices are employed to optimize their performance. This includes regular inspection and maintenance to detect any signs of wear, fatigue, or damage that could compromise the rails' ability to handle braking forces. Rail grinding and other maintenance techniques are also employed to maintain the desired rail profile and surface quality, further improving the rails' ability to handle high-speed train braking forces. Overall, steel rails are designed and maintained to meet the demanding requirements of high-speed train braking forces. Through their material properties, elasticity, smooth surface, and proper maintenance, steel rails ensure safe and efficient deceleration of high-speed trains, providing a reliable and secure transportation system.

- Q: How are steel rails protected from electrical interference?

- Steel rails are protected from electrical interference through a process known as bonding. Bonding refers to the practice of providing a low-resistance electrical connection between different metal components, such as steel rails, to eliminate any potential differences in electrical potential. To protect steel rails from electrical interference, bonding cables or wires are installed at regular intervals along the rail tracks. These cables or wires are typically made of copper or other highly conductive materials. They are securely connected to the steel rails using specialized clamps or welded joints. The bonding cables create a continuous electrical path along the rail tracks, ensuring that any electrical current or interference is quickly and efficiently dispersed. By providing a low-resistance path, the bonding cables help to prevent the buildup of electrical potential differences between different sections of the rail tracks, minimizing the risk of electrical interference. Furthermore, the bonding cables also serve another important purpose: they help to reduce the risk of electrical shock hazards for railway personnel and passengers. By creating a continuous electrical connection, any stray electrical currents or faults are safely directed away from the steel rails and into the grounding system, preventing potential harm to individuals in close proximity to the tracks. Overall, bonding is a crucial method for protecting steel rails from electrical interference. It ensures the safe and efficient operation of railway systems by effectively dispersing electrical currents and preventing potential hazards associated with electrical interference.

- Q: How does the weight of a steel rail affect its performance?

- The weight of a steel rail directly influences its performance. A heavier rail provides greater stability and strength to support heavy loads and withstand the stress and impact of passing trains. It also helps to minimize track movement, reduce vibrations, and increase the overall lifespan of the rail.

Send your message to us

Hot Rolled Light Steel Rail with High Quality 55Q

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords