Hot Rolled Grade ASTM A36 S235JR SS400 Steel Flat Bar Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Sizes

Details of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Sizes

Name | Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Sizes |

Shape | Flat Bar |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

steel flat bar grade | A36, Q235, Q195, SS400, St37-2 |

steel flat bar standard | GB, ASTM, AISI, EN, JIS |

steel flat bar thickness | 1.8mm-17.75mm |

steel flat bar width | 10mm-870mm |

steel flat bar length | 6m, 9m, 12m or as customer requirement |

steel flat bar technique | Slitting hot rolled steel coil |

Specification of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Sizes

Width | Thickness | Length | Theoretical Weight |

(mm) | (mm) | (m) | (kg/m) |

20 | 2 | 6/9/12 | 0.31 |

20 | 2.5 | 6/9/12 | 0.39 |

20 | 2.75 | 6/9/12 | 0.43 |

25 | 2.5 | 6/9/12 | 0.49 |

25 | 3.75 | 6/9/12 | 0.74 |

30 | 2.5 | 6/9/12 | 0.59 |

30 | 3.5 | 6/9/12 | 0.82 |

30 | 9.75 | 6/9/12 | 2.3 |

40 | 3.5 | 6/9/12 | 1.1 |

40 | 4.75 | 6/9/12 | 1.5 |

40 | 11.75 | 6/9/12 | 3.69 |

50 | 2.75 | 6/9/12 | 1.08 |

50 | 4.5 | 6/9/12 | 1.77 |

50 | 9.75 | 6/9/12 | 3.83 |

60 | 5.5 | 6/9/12 | 2.6 |

60 | 7.5 | 6/9/12 | 3.53 |

60 | 11.5 | 6/9/12 | 5.42 |

80 | 5.5 | 6/9/12 | 3.45 |

80 | 7.5 | 6/9/12 | 4.71 |

80 | 11.75 | 6/9/12 | 7.38 |

100 | 3.25 | 6/9/12 | 2.55 |

100 | 4.75 | 6/9/12 | 3.73 |

100 | 7.5 | 6/9/12 | 5.89 |

120 | 9.75 | 6/9/12 | 9.18 |

120 | 11.75 | 6/9/12 | 11.07 |

150 | 9.75 | 6/9/12 | 11.48 |

150 | 11.5 | 6/9/12 | 13.54 |

150 | 13.5 | 6/9/12 | 15.9 |

160 | 11.75 | 6/9/12 | 14.76 |

200 | 9.5 | 6/9/12 | 14.92 |

250 | 5.75 | 6/9/12 | 11.28 |

340 | 7.75 | 6/9/12 | 20.68 |

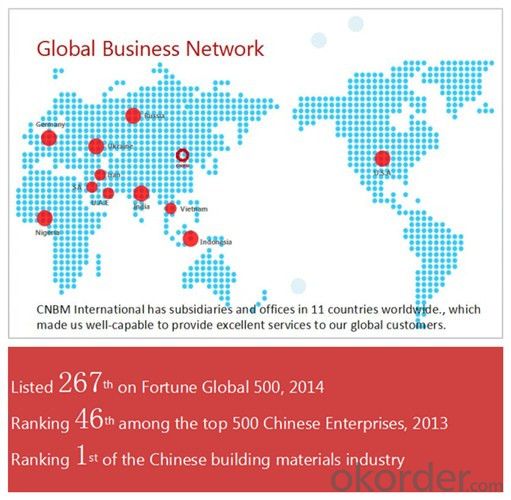

CNBM Introduction of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Sizes Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Sizes

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

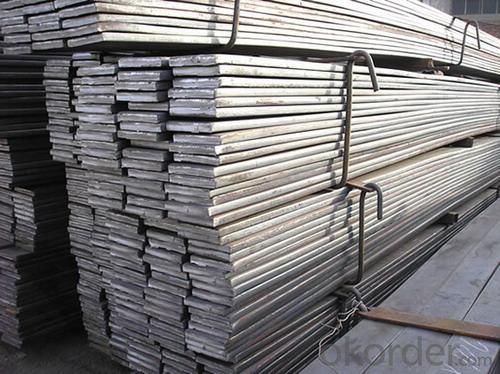

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the applications of special steel in the railway industry?

- Special steel has a wide range of applications in the railway industry. It is commonly used in the manufacturing of rails, which need to be durable and able to withstand heavy loads and constant wear and tear. Special steel is also used in the construction of railway bridges and tunnels, as it offers high strength and resistance to corrosion. Additionally, special steel is used in the production of various railway components such as wheels, axles, and couplers, ensuring safety and reliability in train operation.

- Q: How does the composition of special steel affect its mechanical properties?

- The composition of special steel significantly affects its mechanical properties. Various alloying elements such as carbon, manganese, chromium, nickel, and others are added in specific quantities to enhance the steel's strength, hardness, toughness, and corrosion resistance. The presence and ratio of these elements determine the steel's microstructure, which in turn determines its mechanical properties. For example, higher carbon content increases hardness and strength, while manganese improves toughness. Similarly, chromium and nickel increase corrosion resistance and provide better heat resistance. Therefore, the composition of special steel plays a crucial role in defining its mechanical properties.

- Q: Can special steel be used for making surgical instruments?

- Surgical instruments can indeed be made using special steel. This type of steel, also referred to as surgical steel or medical-grade steel, has been specifically engineered to meet the rigorous standards required for medical and surgical applications. With its exceptional resistance to corrosion, impressive strength and durability, and ability to endure repeated sterilization processes without compromising its properties, special steel is highly regarded. Surgical instruments crafted from this material are renowned for their accuracy, dependability, and capacity to maintain a sharp cutting edge. These instruments play a crucial role in a variety of surgical procedures, such as cutting, dissecting, manipulating, and suturing tissues. By utilizing special steel, surgical instruments can be guaranteed to be safe, hygienic, and appropriate for use within medical environments.

- Q: Can special steel be used in the production of springs for watches?

- Yes, special steel can be used in the production of springs for watches. Special steel, such as stainless steel or high carbon steel, is often preferred for watch springs due to its excellent strength, durability, and resistance to corrosion, ensuring reliable and long-lasting performance of the watch.

- Q: What are the different methods of surface pickling for special steel?

- There are several methods of surface pickling that can be used for special steel. These methods include: 1. Acid Pickling: This is the most common method used for pickling special steel. It involves immersing the steel in an acid solution, usually hydrochloric acid or sulfuric acid, to remove any surface impurities. The acid reacts with the oxide layer on the steel, dissolving it and leaving behind a clean surface. 2. Electrolytic Pickling: In this method, an electric current is passed through the steel while it is immersed in an electrolyte solution. This causes a chemical reaction that removes the surface impurities. Electrolytic pickling is a more controlled process and can be used to achieve a more uniform surface finish compared to acid pickling. 3. Mechanical Pickling: This method involves using mechanical means to remove the surface impurities from the steel. It can be done using abrasive materials, such as sandpaper or wire brushes, to physically scrub the surface and remove any scale or rust. Mechanical pickling is often used in combination with acid or electrolytic pickling to achieve the desired surface finish. 4. Passivation: After pickling, special steel can undergo passivation to enhance its corrosion resistance. Passivation involves treating the steel with a chemical solution, typically nitric acid or citric acid, to create a protective oxide layer on the surface. This layer helps to prevent further corrosion and improves the overall durability of the steel. It is important to note that the specific method of surface pickling used for special steel may vary depending on the type of steel, the desired surface finish, and the intended application. Therefore, it is crucial to consult with experts or follow the manufacturer's guidelines to ensure the appropriate method is used for pickling special steel.

- Q: How is special steel used in the marine supply chain?

- Special steel is used in the marine supply chain for various purposes. It is commonly used in the construction of ships and offshore structures due to its high strength and corrosion resistance properties. Special steel is also used in the manufacturing of marine equipment such as propellers, shafts, and valves, ensuring reliable performance and durability in harsh marine environments. Additionally, special steel plays a crucial role in the production of marine components, ensuring the safety and efficiency of the marine supply chain.

- Q: How does precipitation hardening enhance the strength of special steel?

- The process of precipitation hardening, which is also referred to as age hardening, serves to boost the strength of specific steel alloys through a heat treatment technique. This technique involves a series of steps that lead to the formation of small particles or precipitates within the microstructure of the material. The strength of special steel is mainly determined by the arrangement and interaction of its atoms. Initially, the atoms of the alloy are randomly distributed, resulting in a relatively soft and malleable substance. However, through precipitation hardening, the formation of precipitates during the heat treatment process plays a vital role in strengthening the steel. The process commences by subjecting the steel to a high temperature, referred to as the solution treatment or aging temperature. This elevated temperature allows the atoms to dissolve and form a solid solution. Subsequently, the alloy is rapidly cooled to preserve the supersaturated state of the solution. After the rapid cooling, the steel is exposed to a lower temperature, known as the aging temperature. During this stage, the dissolved atoms start to migrate and cluster together, forming small precipitates within the microstructure of the material. These precipitates act as obstacles to the movement of dislocations, which are the primary carriers of plastic deformation in metals. The presence of these precipitates hampers the movement of dislocations, making it more challenging for them to glide through the crystal lattice. Consequently, the strength of the steel is significantly enhanced. The dislocation obstacles provided by the precipitates increase the resistance to deformation, resulting in improved hardness and strength. Furthermore, the size, distribution, and uniformity of the precipitates play a crucial role in determining the extent of strength enhancement. Smaller and more evenly distributed precipitates offer a higher density of obstacles, leading to a greater strengthening effect. Additionally, the process of precipitation hardening also influences other material properties, such as corrosion resistance and toughness. To conclude, precipitation hardening strengthens special steel by creating small precipitates within its microstructure. These precipitates impede the movement of dislocations, increasing resistance to deformation and resulting in improved hardness and strength. This heat treatment process is pivotal in the development of high-performance special steel alloys utilized in diverse industries.

- Q: What are the common challenges in heat treatment of special steel?

- The heat treatment of special steel presents several common challenges that need to be carefully addressed in order to achieve desired material properties. One of the key challenges is the need for precise temperature control during the heating and cooling processes. Special steels often have specific heat treatment temperature ranges that need to be strictly followed to achieve the desired microstructure and mechanical properties. Failure to maintain precise temperature control can result in inadequate or inconsistent heat treatment, leading to suboptimal material performance. Another challenge is the potential for distortion or warping of the steel components during the heat treatment process. Special steels often have complex shapes or intricate designs, making them more susceptible to distortion when exposed to high temperatures. This distortion can negatively impact the dimensional accuracy and overall quality of the final product. Hence, careful consideration must be given to the selection of appropriate heating and cooling methods, as well as the use of fixtures or jigs to minimize distortion. Furthermore, special steels may contain alloying elements that can have a significant influence on the heat treatment process. Alloying elements such as chromium, molybdenum, or vanadium can alter the hardenability, tempering response, or transformation behavior of the steel. These elements may introduce additional challenges when determining the optimal heat treatment parameters, as their presence can necessitate adjustments to the heating and cooling rates, soak times, or quenching media. Lastly, achieving uniformity in heat treatment across a batch of special steel components can be a challenge. Variations in size, shape, or composition within a batch can lead to inconsistent heat treatment results. Controlling the heating and cooling rates, ensuring proper circulation of the heat treatment media, and implementing effective process monitoring techniques are essential for achieving consistent and uniform material properties. In conclusion, the common challenges in heat treatment of special steel include precise temperature control, distortion/warping, the influence of alloying elements, and achieving uniformity across a batch. Addressing these challenges requires a thorough understanding of the steel's composition, careful process planning, and the use of appropriate process controls and monitoring techniques.

- Q: How does special steel contribute to the manufacturing of hydraulic components?

- Special steel plays a crucial role in the manufacturing of hydraulic components by providing the required strength, durability, and corrosion resistance necessary for these components to perform optimally. The unique properties of special steel, such as high tensile strength and excellent machinability, ensure that hydraulic components can withstand high pressure and repetitive movements without deformation or failure. Additionally, the corrosion resistance of special steel helps protect hydraulic components from the harsh operating environments they often encounter, extending their lifespan and reducing maintenance requirements.

- Q: How is special steel used in the production of cutting inserts?

- The unique properties of special steel make it the ideal choice for producing cutting inserts. Cutting inserts are utilized in machining operations to shape and remove material from a workpiece. These inserts must possess the ability to endure high temperatures, resist wear and abrasion, and maintain their sharp cutting edges for extended periods. Commonly referred to as tool steel, special steel is specifically engineered to meet these requirements. It is an alloy that incorporates a variety of elements like chromium, tungsten, vanadium, and molybdenum, which enhance its mechanical properties. With its exceptional hardness, toughness, and resistance to high temperatures, special steel is a suitable material for cutting inserts. To further augment its properties, the special steel employed in manufacturing cutting inserts undergoes a series of processes, including heat treatment. This process involves subjecting the steel to specific temperatures and rapidly cooling it, resulting in increased strength and hardness. By undergoing heat treatment, the cutting inserts become capable of withstanding the extreme forces and temperatures encountered during machining operations. Moreover, special steel can be coated with materials like titanium nitride or diamond-like carbon to enhance its performance. These coatings contribute to the hardness, friction reduction, and overall wear resistance of the cutting inserts, ultimately extending their lifespan and improving efficiency. In conclusion, special steel is selected for the production of cutting inserts due to its remarkable hardness, toughness, high-temperature resistance, and wear resistance. These properties enable the cutting inserts to withstand the demanding conditions of machining operations and retain their sharp cutting edges for prolonged periods. As a result, material removal is carried out efficiently and precisely.

Send your message to us

Hot Rolled Grade ASTM A36 S235JR SS400 Steel Flat Bar Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords