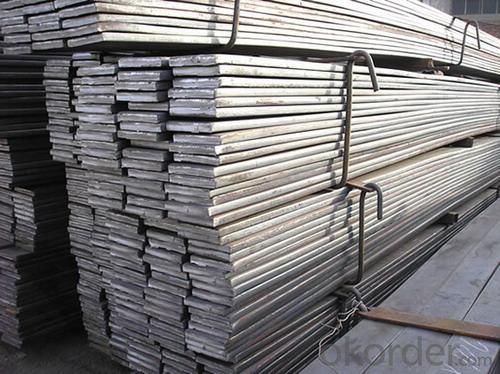

Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Picture

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Picture

Details of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Picture

Name | Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Picture |

Shape | Flat Bar |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

steel flat bar grade | A36, Q235, Q195, SS400, St37-2 |

steel flat bar standard | GB, ASTM, AISI, EN, JIS |

steel flat bar thickness | 1.8mm-17.75mm |

steel flat bar width | 10mm-870mm |

steel flat bar length | 6m, 9m, 12m or as customer requirement |

steel flat bar technique | Slitting hot rolled steel coil |

Specification of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Picture

Width | Thickness | Length | Theoretical Weight |

(mm) | (mm) | (m) | (kg/m) |

20 | 2 | 6/9/12 | 0.31 |

20 | 2.5 | 6/9/12 | 0.39 |

20 | 2.75 | 6/9/12 | 0.43 |

25 | 2.5 | 6/9/12 | 0.49 |

25 | 3.75 | 6/9/12 | 0.74 |

30 | 2.5 | 6/9/12 | 0.59 |

30 | 3.5 | 6/9/12 | 0.82 |

30 | 9.75 | 6/9/12 | 2.3 |

40 | 3.5 | 6/9/12 | 1.1 |

40 | 4.75 | 6/9/12 | 1.5 |

40 | 11.75 | 6/9/12 | 3.69 |

50 | 2.75 | 6/9/12 | 1.08 |

50 | 4.5 | 6/9/12 | 1.77 |

50 | 9.75 | 6/9/12 | 3.83 |

60 | 5.5 | 6/9/12 | 2.6 |

60 | 7.5 | 6/9/12 | 3.53 |

60 | 11.5 | 6/9/12 | 5.42 |

80 | 5.5 | 6/9/12 | 3.45 |

80 | 7.5 | 6/9/12 | 4.71 |

80 | 11.75 | 6/9/12 | 7.38 |

100 | 3.25 | 6/9/12 | 2.55 |

100 | 4.75 | 6/9/12 | 3.73 |

100 | 7.5 | 6/9/12 | 5.89 |

120 | 9.75 | 6/9/12 | 9.18 |

120 | 11.75 | 6/9/12 | 11.07 |

150 | 9.75 | 6/9/12 | 11.48 |

150 | 11.5 | 6/9/12 | 13.54 |

150 | 13.5 | 6/9/12 | 15.9 |

160 | 11.75 | 6/9/12 | 14.76 |

200 | 9.5 | 6/9/12 | 14.92 |

250 | 5.75 | 6/9/12 | 11.28 |

340 | 7.75 | 6/9/12 | 20.68 |

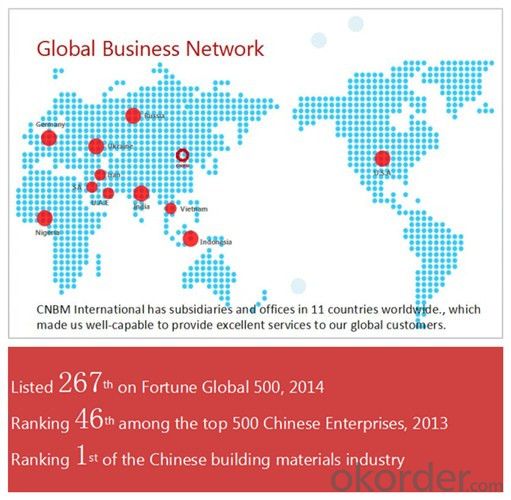

CNBM Introduction of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Picture Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Picture

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the applications of special steel in the agriculture supply chain?

- Special steel has various applications in the agriculture supply chain. It is commonly used in the manufacturing of machinery and equipment such as tractors, harvesters, and irrigation systems. Special steel's high tensile strength and resistance to corrosion make it ideal for these applications, ensuring durability and longevity in agricultural operations. Additionally, special steel is used in the production of storage tanks, silos, and processing equipment, providing the necessary strength and reliability for storing and handling agricultural products. Overall, special steel contributes to the efficiency and effectiveness of the agriculture supply chain by enabling the development of robust and reliable equipment and infrastructure.

- Q: How does special steel perform in abrasive wear conditions?

- Special steel performs well in abrasive wear conditions due to its high hardness and toughness. It has excellent resistance to abrasion, which allows it to withstand the rubbing, scraping, and grinding that occurs in abrasive environments. The unique composition and heat treatment of special steel enhance its ability to resist wear and maintain its structural integrity, making it an ideal choice for applications where abrasive wear is a concern.

- Q: What are the factors to consider when selecting special steel for a specific application?

- When selecting special steel for a specific application, there are several important factors to consider: 1. Mechanical properties: The mechanical properties of the steel, such as strength, hardness, toughness, and ductility, are crucial in determining its suitability for a particular application. It is important to match the steel's mechanical properties to the specific requirements of the application to ensure optimal performance and safety. 2. Corrosion resistance: Depending on the application, it is essential to consider the steel's resistance to corrosion. Different environments, such as marine, chemical, or high-temperature conditions, may require specific corrosion-resistant alloys or coatings to ensure the longevity and reliability of the steel in service. 3. Temperature resistance: The ability of the steel to withstand high or low temperatures without losing its mechanical properties is crucial in many applications. Factors such as thermal expansion, thermal conductivity, and resistance to thermal fatigue must be considered to ensure the steel can perform effectively in the intended environment. 4. Weldability and fabricability: If the steel needs to be welded or fabricated into complex shapes, the ease of weldability and fabricability becomes an important factor. Some steels may require specialized welding techniques or preheating to avoid cracking or distortion during fabrication. 5. Cost: Cost is also a key consideration when selecting special steel for a specific application. It is important to balance the desired properties of the steel with the available budget to ensure cost-effectiveness without compromising performance or safety. 6. Availability: The availability of the chosen steel grade in the required form, size, and quantity is another critical factor. It is important to ensure that the selected steel can be easily sourced and obtained within the required timeframe to avoid project delays or cost overruns. 7. Compliance with standards and specifications: Depending on the industry or application, there may be specific standards, specifications, or regulations that the steel must comply with. It is essential to select a steel grade that meets these requirements to ensure compliance and maintain the necessary certifications or approvals. By considering these factors, engineers and manufacturers can make an informed decision when selecting special steel for a specific application, ensuring optimal performance, durability, and safety.

- Q: What are the challenges in forging special steel?

- Forging special steel poses several challenges due to its unique composition and properties. Firstly, special steels often have high carbon content, making them harder to forge compared to lower carbon steels. The high carbon content increases the risk of cracking and requires careful temperature control during the forging process to prevent metallurgical issues. Secondly, special steels may contain alloying elements like chromium, molybdenum, or nickel, which enhance their specific properties. However, these alloying elements can also contribute to increased hardness and brittleness, making the forging process more challenging. Special attention must be given to heat treatment procedures to achieve the desired balance of strength and toughness. Furthermore, the complex internal structure of special steels, including the presence of inclusions and segregation, can further complicate the forging process. These internal defects can lead to uneven deformation, inadequate mechanical properties, or even failure during forging, necessitating meticulous quality control measures. Lastly, the cost of special steel materials is generally higher than that of regular steels, making any errors or wasted materials during the forging process more significant. The need for specialized equipment, skilled labor, and stringent quality assurance further adds to the challenges associated with forging special steel. Overall, forging special steel demands expertise, precision, and meticulous control of various parameters to ensure the desired mechanical properties and quality of the final product.

- Q: How does special steel contribute to reducing product waste?

- Special steel contributes to reducing product waste by offering superior strength, durability, and corrosion resistance. This allows manufacturers to produce longer-lasting and more reliable products, minimizing the need for frequent replacements. Additionally, special steel's high precision and customization capabilities enable the creation of components with tight tolerances, reducing the risk of assembly errors and subsequent product failures. Consequently, special steel helps optimize product performance and longevity, thereby reducing waste generated from premature product disposal.

- Q: What are the safety benefits of using special steel?

- Using special steel provides several safety benefits. Firstly, special steel is known for its high strength and durability, which makes it resistant to deformation and fracture, reducing the risk of structural failures and accidents. Secondly, special steel is often designed to withstand extreme temperatures, corrosion, and wear, making it suitable for various harsh environments and reducing the chances of equipment malfunction or failure. Additionally, special steel is frequently used in safety-critical industries such as aerospace and automotive, where it undergoes rigorous testing and quality control measures to ensure its reliability and performance. Overall, the use of special steel enhances safety by providing reliable and robust materials for critical applications.

- Q: How does special steel contribute to the manufacturing of fasteners?

- Special steel contributes to the manufacturing of fasteners by providing higher strength, durability, and corrosion resistance compared to regular steel. This allows fasteners to withstand heavy loads, vibrations, and harsh environmental conditions, ensuring their longevity and reliability in various applications. Additionally, special steel can be tailored to specific requirements, enabling the production of fasteners with precise dimensions, shapes, and surface finishes, thereby enhancing their performance and compatibility with different components and structures.

- Q: Can special steel be used in the power generation industry?

- Yes, special steel can be used in the power generation industry. Special steel alloys are commonly used in various power generation components such as turbines, boilers, and generators due to their high strength, corrosion resistance, and heat resistance properties. These alloys are designed to withstand extreme temperatures and pressures, ensuring the reliable and efficient operation of power generation equipment.

- Q: How is corrosion-resistant steel used in marine applications?

- Corrosion-resistant steel is extensively used in marine applications due to its ability to withstand the harsh environment of seawater. It is employed in the construction of various marine structures such as ships, offshore platforms, and coastal infrastructure. This type of steel provides exceptional resistance to corrosion, preventing the degradation of materials and ensuring the longevity and safety of marine structures. Additionally, corrosion-resistant steel is used in the production of marine equipment, such as propellers, valves, and pipelines, as it offers superior durability and protection against corrosion caused by saltwater exposure.

- Q: How does special steel contribute to the defense industry?

- Special steel contributes to the defense industry by providing materials with exceptional strength, durability, and resistance to wear, corrosion, and extreme temperatures. These properties make it ideal for manufacturing military equipment, such as tanks, aircraft, submarines, and artillery, ensuring their reliability and long service life. Additionally, special steel's high hardness and toughness make it suitable for producing armor plates and ballistic protection systems, enhancing the safety and survivability of military personnel.

Send your message to us

Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Picture

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords