Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar

Details of Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar

Name | Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar |

Shape | Flat Bar |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

steel flat bar grade | A36, Q235, Q195, SS400, St37-2 |

steel flat bar standard | GB, ASTM, AISI, EN, JIS |

steel flat bar thickness | 1.8mm-17.75mm |

steel flat bar width | 10mm-870mm |

steel flat bar length | 6m, 9m, 12m or as customer requirement |

steel flat bar technique | Slitting hot rolled steel coil |

Specification of Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar

Width | Thickness | Length | Theoretical Weight |

(mm) | (mm) | (m) | (kg/m) |

20 | 2 | 6/9/12 | 0.31 |

20 | 2.5 | 6/9/12 | 0.39 |

20 | 2.75 | 6/9/12 | 0.43 |

25 | 2.5 | 6/9/12 | 0.49 |

25 | 3.75 | 6/9/12 | 0.74 |

30 | 2.5 | 6/9/12 | 0.59 |

30 | 3.5 | 6/9/12 | 0.82 |

30 | 9.75 | 6/9/12 | 2.3 |

40 | 3.5 | 6/9/12 | 1.1 |

40 | 4.75 | 6/9/12 | 1.5 |

40 | 11.75 | 6/9/12 | 3.69 |

50 | 2.75 | 6/9/12 | 1.08 |

50 | 4.5 | 6/9/12 | 1.77 |

50 | 9.75 | 6/9/12 | 3.83 |

60 | 5.5 | 6/9/12 | 2.6 |

60 | 7.5 | 6/9/12 | 3.53 |

60 | 11.5 | 6/9/12 | 5.42 |

80 | 5.5 | 6/9/12 | 3.45 |

80 | 7.5 | 6/9/12 | 4.71 |

80 | 11.75 | 6/9/12 | 7.38 |

100 | 3.25 | 6/9/12 | 2.55 |

100 | 4.75 | 6/9/12 | 3.73 |

100 | 7.5 | 6/9/12 | 5.89 |

120 | 9.75 | 6/9/12 | 9.18 |

120 | 11.75 | 6/9/12 | 11.07 |

150 | 9.75 | 6/9/12 | 11.48 |

150 | 11.5 | 6/9/12 | 13.54 |

150 | 13.5 | 6/9/12 | 15.9 |

160 | 11.75 | 6/9/12 | 14.76 |

200 | 9.5 | 6/9/12 | 14.92 |

250 | 5.75 | 6/9/12 | 11.28 |

340 | 7.75 | 6/9/12 | 20.68 |

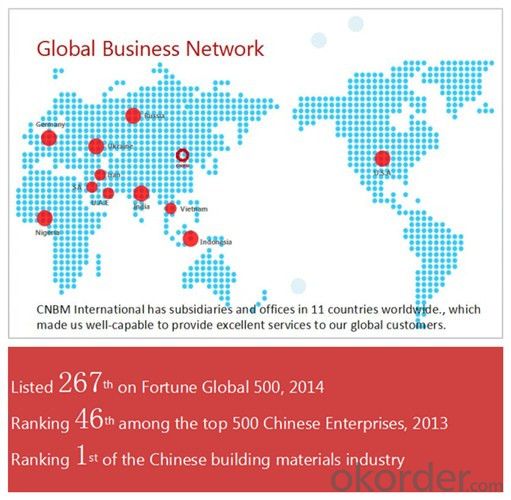

CNBM Introduction of Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar Supplier

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

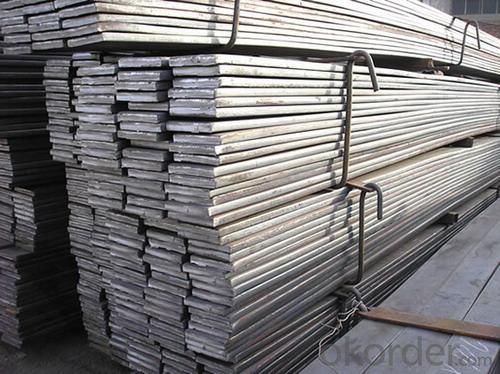

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: Can special steel be used in the battery manufacturing industry?

- Yes, special steel can be used in the battery manufacturing industry. Special steel, such as stainless steel or nickel-plated steel, can be used for battery casings, terminals, and other components due to its durability, corrosion resistance, and electrical conductivity properties.

- Q: What are the main applications of special steel in the agricultural sector?

- Special steel has various applications in the agricultural sector, primarily in the manufacturing of machinery and equipment. It is used in the production of durable and high-strength components such as plows, tillers, harvesters, and irrigation systems. Special steel's properties, including corrosion resistance and ability to withstand harsh conditions, make it ideal for constructing farm implements that can withstand the demands of agricultural operations. Additionally, special steel is used in the manufacturing of storage tanks, silos, and structures, ensuring the longevity and reliability of agricultural infrastructure.

- Q: How does special steel contribute to the strength of products?

- Special steel contributes to the strength of products in several ways. Firstly, special steel is engineered to have enhanced mechanical properties, such as high tensile strength, toughness, and hardness. This makes it ideal for applications where strength is crucial, such as in the construction industry, automotive manufacturing, and aerospace engineering. Moreover, special steel can be customized to meet specific requirements, allowing manufacturers to tailor the material's composition and properties to suit their products. This flexibility ensures that the steel used in various components is optimized for maximum strength, durability, and performance. Additionally, special steel undergoes various heat treatment processes, such as quenching and tempering, which further enhance its strength. These processes modify the microstructure of the steel, resulting in improved hardness and resistance to wear and fatigue. As a result, products made from special steel can withstand heavy loads, harsh environments, and repetitive stress, ensuring their long-term reliability and longevity. Furthermore, special steel often exhibits excellent corrosion resistance, making it suitable for applications exposed to corrosive environments, such as marine or chemical industries. By preventing the degradation of the material, corrosion resistance contributes to the overall strength and lifespan of the product. In summary, special steel greatly contributes to the strength of products by providing enhanced mechanical properties, customized composition, heat treatment processes, and corrosion resistance. These factors combine to ensure that products made from special steel can withstand high stresses, extreme conditions, and offer exceptional performance, making them indispensable in various industries.

- Q: What are the different methods for improving the impact resistance of special steel?

- There are several methods for improving the impact resistance of special steel. One commonly used method is through heat treatment processes such as quenching and tempering, which involve rapid cooling of the steel followed by controlled heating and cooling to achieve desired mechanical properties. Another method is alloying, where elements such as nickel, chromium, and molybdenum are added to the steel to enhance its toughness and resistance to impact. Additionally, processes like shot peening and surface hardening can be employed to increase the steel's resistance to impact by inducing compressive stresses on its surface.

- Q: Is special steel suitable for electrical and electronic applications?

- Yes, special steel is suitable for electrical and electronic applications. Special steel is often used in electrical and electronic applications due to its excellent conductivity, high strength, and resistance to corrosion and wear. It is commonly utilized in the manufacturing of electrical connectors, circuit breakers, transformers, and various other components in the electrical and electronic industry.

- Q: Can special steel be used in the medical industry?

- Yes, special steel can be used in the medical industry. It is commonly employed in the production of surgical instruments, medical implants, and equipment due to its high strength, corrosion resistance, and biocompatibility. Special steel alloys, such as stainless steel and titanium alloys, are extensively utilized in various medical applications to ensure patient safety and enhance the effectiveness of medical procedures.

- Q: What are the properties of duplex stainless steel?

- Duplex stainless steel is a type of stainless steel that possesses a unique combination of properties. It is highly corrosion resistant, making it suitable for use in aggressive environments, such as those containing chlorides or acids. It also exhibits excellent strength and toughness, allowing it to withstand high pressures and temperatures. Additionally, duplex stainless steel has good weldability and formability, making it versatile for various fabrication processes. Its dual-phase microstructure provides a balance of ferrite and austenite, resulting in improved resistance to stress corrosion cracking and higher resistance to pitting and crevice corrosion compared to other types of stainless steel.

- Q: How does special steel contribute to the chemical processing aftermarket industry?

- The chemical processing aftermarket industry heavily relies on special steel, which offers a wide range of benefits to enhance the efficiency and performance of equipment. Firstly, special steel is well-known for its exceptional strength and durability, making it ideal for applications involving high pressure, extreme temperatures, and corrosive environments. This durability ensures that the equipment can withstand challenging conditions and operate reliably for extended periods, reducing the need for frequent maintenance and replacement. Furthermore, special steel possesses excellent resistance to corrosion, oxidation, and chemical reactions, which are common challenges in the chemical processing industry. This resistance allows the equipment to handle various chemicals without deteriorating or contaminating the process, ensuring the quality and safety of the end products. Additionally, special steel can withstand the formation of scale, deposits, and other contaminants that can hinder equipment efficiency, reducing the frequency of cleaning and maintenance. Moreover, special steel offers superior mechanical properties such as toughness, hardness, and impact resistance, which are essential for handling heavy loads and abrasive materials. This ensures that the equipment can withstand demanding operational conditions and maintain its performance over time, resulting in enhanced productivity and reduced downtime. Another significant contribution of special steel to the chemical processing aftermarket industry is its versatility. It can be customized and tailored to meet specific requirements, allowing for the manufacturing of complex parts and components essential for various chemical processes. Special steel can be fabricated into different shapes and sizes, enabling the creation of intricate designs and structures that optimize equipment efficiency and effectiveness. In conclusion, special steel is vital to the chemical processing aftermarket industry due to its exceptional strength, durability, resistance to corrosion and chemical reactions, as well as its versatility. By providing reliable and high-performance equipment, special steel significantly contributes to the overall efficiency, safety, and productivity of chemical processing operations.

- Q: What is the role of alloying elements in special steel?

- The role of alloying elements in special steel is to enhance its properties, such as strength, hardness, corrosion resistance, and heat resistance. These elements are added to the steel during the manufacturing process to create alloys with specific characteristics required for various applications. Alloying elements can alter the microstructure of the steel, improving its performance and making it suitable for specialized uses in industries like aerospace, automotive, construction, and oil and gas.

- Q: How does special steel resist wear and tear?

- Special steel resists wear and tear due to its unique composition and manufacturing process. It is typically alloyed with elements like chromium, nickel, and molybdenum, which enhance its hardness, strength, and corrosion resistance. Additionally, special steel undergoes heat treatment processes such as quenching and tempering, which further increase its durability and ability to withstand various mechanical stresses. This combination of alloying elements and heat treatment results in a steel that is highly resistant to wear, friction, and fatigue, making it suitable for demanding applications where durability is crucial.

Send your message to us

Hot Rolled Grade ASTM A36_Q235 MS Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords