Hot Rolled Grade JIS S355JR Steel Flat Bar Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Grade JIS S355JR Steel Flat Bar

Details of Hot Rolled Grade JIS S355JR Steel Flat Bar

Name | Hot Rolled Grade JIS S355JR Steel Flat Bar Sizes |

Shape | Flat Bar |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

steel flat bar grade | Q195,Q215,Q235 Q345,ST-37,ST-53,S275JR.S355JR,SS400 |

steel flat bar standard | GB, ASTM, AISI, EN, JIS |

steel flat bar thickness | 1.8mm-17.75mm |

steel flat bar width | 10mm-870mm |

steel flat bar length | 6m, 9m, 12m or as customer requirement |

steel flat bar technique | Slitting hot rolled steel coil |

Specification of Hot Rolled GradeJIS S355JR Steel Flat Bar

Width | Thickness | Length | Theoretical Weight |

(mm) | (mm) | (m) | (kg/m) |

20 | 2 | 6/9/12 | 0.31 |

20 | 2.5 | 6/9/12 | 0.39 |

20 | 2.75 | 6/9/12 | 0.43 |

25 | 2.5 | 6/9/12 | 0.49 |

25 | 3.75 | 6/9/12 | 0.74 |

30 | 2.5 | 6/9/12 | 0.59 |

30 | 3.5 | 6/9/12 | 0.82 |

30 | 9.75 | 6/9/12 | 2.3 |

40 | 3.5 | 6/9/12 | 1.1 |

40 | 4.75 | 6/9/12 | 1.5 |

40 | 11.75 | 6/9/12 | 3.69 |

50 | 2.75 | 6/9/12 | 1.08 |

50 | 4.5 | 6/9/12 | 1.77 |

50 | 9.75 | 6/9/12 | 3.83 |

60 | 5.5 | 6/9/12 | 2.6 |

60 | 7.5 | 6/9/12 | 3.53 |

60 | 11.5 | 6/9/12 | 5.42 |

80 | 5.5 | 6/9/12 | 3.45 |

80 | 7.5 | 6/9/12 | 4.71 |

80 | 11.75 | 6/9/12 | 7.38 |

100 | 3.25 | 6/9/12 | 2.55 |

100 | 4.75 | 6/9/12 | 3.73 |

100 | 7.5 | 6/9/12 | 5.89 |

120 | 9.75 | 6/9/12 | 9.18 |

120 | 11.75 | 6/9/12 | 11.07 |

150 | 9.75 | 6/9/12 | 11.48 |

150 | 11.5 | 6/9/12 | 13.54 |

150 | 13.5 | 6/9/12 | 15.9 |

160 | 11.75 | 6/9/12 | 14.76 |

200 | 9.5 | 6/9/12 | 14.92 |

250 | 5.75 | 6/9/12 | 11.28 |

340 | 7.75 | 6/9/12 | 20.68 |

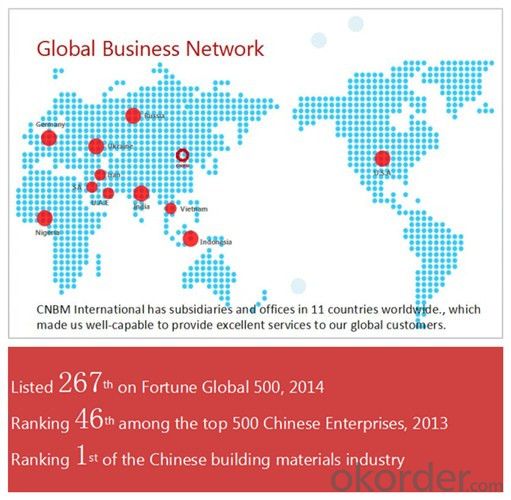

CNBM Introduction of Hot Rolled Grade JIS S355JR Steel Flat Bar Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Hot Rolled Grade JIS S355JR Steel Flat Bar

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

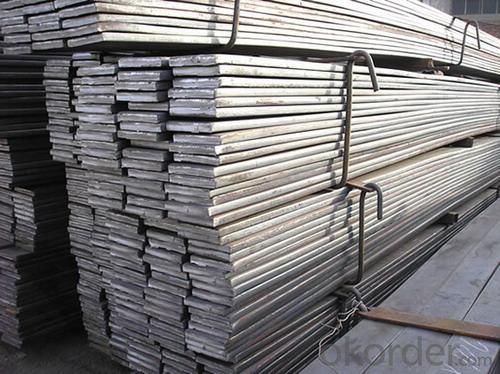

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the common defects found in special steel production?

- Various defects can be found in the production of special steel, including the following: 1. Inclusions: Impurities or foreign materials can become trapped in the steel during manufacturing, weakening its strength and overall quality. 2. Segregation: Uneven distribution of elements within the steel can occur due to fluctuations in temperature or composition during production. This can lead to inconsistencies in mechanical properties and reduce reliability. 3. Cracks: Improper cooling or excessive stress during manufacturing can cause cracks in the steel, significantly compromising its strength and making it more vulnerable to failure. 4. Decarburization: The surface of the steel can lose carbon when exposed to high temperatures or oxidizing environments, resulting in decreased hardness and strength. 5. Laminations: Improper rolling or forging techniques can cause layered sheets to form within the steel, weakening its structure and potentially causing failure under stress. 6. Dimensional variations: Precise control of dimensions is crucial in special steel production, but inconsistencies in cooling or machining can lead to variations that affect fit, function, and overall performance. 7. Non-uniform microstructure: Inconsistent cooling rates or other processing factors can result in a non-uniform microstructure in the steel, causing variations in hardness, strength, and other mechanical properties that impact overall quality. Manufacturers must implement rigorous quality control measures to detect and minimize these defects during special steel production. Regular inspections, testing, and adherence to industry standards are essential to ensure that the final product meets desired specifications and is free from common defects.

- Q: How is special steel used in the production of cutting blades?

- Special steel is used in the production of cutting blades due to its exceptional hardness, durability, and resistance to wear. This type of steel is specifically designed to withstand the high levels of stress and heat generated during cutting processes. It allows the blades to retain their sharpness for a longer period, resulting in improved cutting performance and longer lifespan. Additionally, special steel can be tailored to meet specific requirements, such as corrosion resistance or high impact strength, making it a preferred choice for various cutting applications.

- Q: What are the different surface defects in special steel?

- Some common surface defects in special steel include scale, pits, scratches, cracks, and inclusions. Scale refers to the formation of oxide layers on the surface, while pits are small depressions caused by corrosion or mechanical damage. Scratches can occur during handling or processing, while cracks are often due to excessive stress or improper heat treatment. Inclusions are foreign particles or impurities embedded in the steel, which can impact its overall quality and performance.

- Q: How does special steel contribute to the aerospace landing gear industry?

- Special steel plays a vital role in the aerospace landing gear industry by providing the necessary strength, durability, and resistance to extreme conditions. It enables the landing gear to withstand heavy loads, high temperatures, and corrosive environments, ensuring the safe landing and takeoff of aircraft. Additionally, special steel's lightweight properties help reduce the overall weight of the landing gear, resulting in improved fuel efficiency and increased payload capacity.

- Q: Can special steel be used for making marine components?

- Yes, special steel can be used for making marine components. Special steel is often chosen for its corrosion resistance, strength, and durability, which are crucial properties required for components used in marine environments. These components need to withstand exposure to seawater, harsh weather conditions, and extreme pressures. Special steel alloys such as stainless steel or duplex steel are commonly used for marine applications due to their excellent resistance to corrosion and ability to maintain structural integrity in marine environments.

- Q: What are the different casting techniques used for special steel?

- Some of the different casting techniques used for special steel include investment casting, sand casting, continuous casting, and centrifugal casting. Each technique has its own advantages and is chosen based on factors such as the complexity of the steel part, the desired quality, and cost considerations.

- Q: What are the different methods of surface ion nitriding for special steel?

- Surface ion nitriding of special steel can be achieved through various methods. These methods encompass: 1. Utilizing DC Plasma Nitriding: Employing direct current (DC) plasma to ionize nitrogen gas, a plasma atmosphere is created. By subjecting the special steel to the plasma chamber and applying high voltage, the ions are accelerated towards the steel's surface, resulting in nitriding. 2. Adopting RF Plasma Nitriding: Similar to DC plasma nitriding, RF (Radio Frequency) plasma nitriding employs a radio frequency power supply to generate plasma instead of direct current. This method allows for better control over the nitriding process and can accommodate more intricate geometries. 3. Employing Pulse Plasma Nitriding: By applying short pulses of high voltage to the steel surface, a plasma discharge is created. These pulses are repeated at regular intervals, enabling precise control over the nitriding process. Pulse plasma nitriding is commonly used for steels with sensitive properties that may be affected by prolonged exposure to high temperatures. 4. Combining Plasma Assisted Nitriding: This method combines plasma nitriding with other surface treatment techniques, such as physical vapor deposition (PVD) or chemical vapor deposition (CVD). Initially, the steel is coated with a thin layer of reactive material, followed by nitriding in a plasma atmosphere. This combination enhances the surface properties of the special steel, such as wear resistance or corrosion resistance. 5. Employing Glow Discharge Nitriding: This method involves placing the special steel in a chamber filled with a nitrogen-rich gas, such as ammonia. Applying high voltage creates a glow discharge, which ionizes the gas and generates nitrogen ions that diffuse into the steel's surface. Glow discharge nitriding is commonly employed for small parts or components with complex shapes. It is crucial to consider factors such as desired properties, steel geometry, and application-specific requirements when selecting the most suitable method for surface ion nitriding of special steel.

- Q: Can special steel be used in the production of hydraulic components?

- Yes, special steel can be used in the production of hydraulic components. Special steels, such as stainless steel or high-strength alloy steels, offer excellent corrosion resistance, high strength, and durability, making them suitable for hydraulic applications where resistance to pressure, fluid flow, and environmental factors is crucial.

- Q: What are the properties of copper alloys?

- Copper alloys have various properties such as high electrical and thermal conductivity, excellent corrosion resistance, good strength and ductility, as well as a pleasing aesthetic appearance. They are also known for their antimicrobial properties and are commonly used in electrical wiring, plumbing systems, and various industrial applications.

- Q: How does tungsten contribute to the properties of special steel?

- Tungsten is a critical element that contributes significantly to the properties of special steel. One of the major benefits of tungsten in steel is its ability to enhance strength and hardness. It forms a solid solution with iron, resulting in a fine-grained microstructure that increases the overall toughness and wear resistance of the steel. Additionally, tungsten helps to improve the high-temperature strength of special steel. It has a high melting point and maintains its strength even at elevated temperatures, making it ideal for applications that require resistance to heat and thermal stress. This characteristic allows special steel with tungsten to be used in environments with extreme temperatures, such as in gas turbines, rocket nozzles, and cutting tools. Tungsten also plays a crucial role in improving the corrosion resistance of special steel. It forms stable carbides that protect against corrosion and erosion, making the steel more durable and long-lasting. This is particularly valuable in industries where the steel is exposed to corrosive environments, such as chemical processing, marine applications, and oil and gas exploration. Furthermore, tungsten contributes to the machinability of special steel. It helps in reducing the built-up edge during cutting operations, resulting in improved surface finish and longer tool life. This characteristic is highly advantageous in industries that require precision machining, such as automotive, aerospace, and tool manufacturing. In summary, tungsten is a vital element in special steel as it enhances strength, hardness, high-temperature performance, corrosion resistance, and machinability. Its unique properties make it an indispensable component in the production of high-quality steel used in various industries.

Send your message to us

Hot Rolled Grade JIS S355JR Steel Flat Bar Sizes

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords