Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue

Details of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue

Name | Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue |

Shape | Flat Bar |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

steel flat bar grade | A36, Q235, Q195, SS400, St37-2 |

steel flat bar standard | GB, ASTM, AISI, EN, JIS |

steel flat bar thickness | 1.8mm-17.75mm |

steel flat bar width | 10mm-870mm |

steel flat bar length | 6m, 9m, 12m or as customer requirement |

steel flat bar technique | Slitting hot rolled steel coil |

Specification of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue

Width | Thickness | Length | Theoretical Weight |

(mm) | (mm) | (m) | (kg/m) |

20 | 2 | 6/9/12 | 0.31 |

20 | 2.5 | 6/9/12 | 0.39 |

20 | 2.75 | 6/9/12 | 0.43 |

25 | 2.5 | 6/9/12 | 0.49 |

25 | 3.75 | 6/9/12 | 0.74 |

30 | 2.5 | 6/9/12 | 0.59 |

30 | 3.5 | 6/9/12 | 0.82 |

30 | 9.75 | 6/9/12 | 2.3 |

40 | 3.5 | 6/9/12 | 1.1 |

40 | 4.75 | 6/9/12 | 1.5 |

40 | 11.75 | 6/9/12 | 3.69 |

50 | 2.75 | 6/9/12 | 1.08 |

50 | 4.5 | 6/9/12 | 1.77 |

50 | 9.75 | 6/9/12 | 3.83 |

60 | 5.5 | 6/9/12 | 2.6 |

60 | 7.5 | 6/9/12 | 3.53 |

60 | 11.5 | 6/9/12 | 5.42 |

80 | 5.5 | 6/9/12 | 3.45 |

80 | 7.5 | 6/9/12 | 4.71 |

80 | 11.75 | 6/9/12 | 7.38 |

100 | 3.25 | 6/9/12 | 2.55 |

100 | 4.75 | 6/9/12 | 3.73 |

100 | 7.5 | 6/9/12 | 5.89 |

120 | 9.75 | 6/9/12 | 9.18 |

120 | 11.75 | 6/9/12 | 11.07 |

150 | 9.75 | 6/9/12 | 11.48 |

150 | 11.5 | 6/9/12 | 13.54 |

150 | 13.5 | 6/9/12 | 15.9 |

160 | 11.75 | 6/9/12 | 14.76 |

200 | 9.5 | 6/9/12 | 14.92 |

250 | 5.75 | 6/9/12 | 11.28 |

340 | 7.75 | 6/9/12 | 20.68 |

CNBM Introduction of Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue Supplier

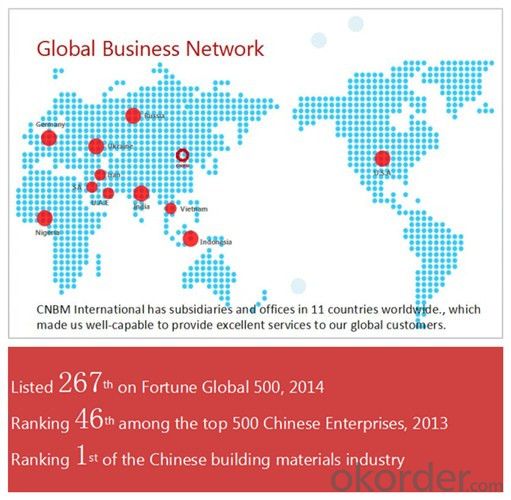

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

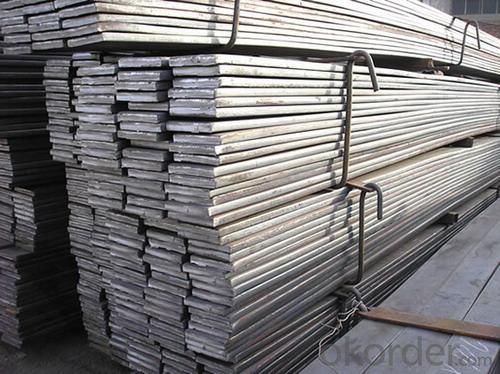

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: Can special steel be used in the production of cutting tools?

- Yes, special steel can be and is commonly used in the production of cutting tools. Special steel, such as high-speed steel or tool steel, is specifically engineered to have superior hardness, toughness, and wear resistance, making it ideal for manufacturing various types of cutting tools like drills, saw blades, milling cutters, and lathe tools.

- Q: Can special steel be used in the oil refinery industry?

- Yes, special steel can be used in the oil refinery industry. Special steels, such as stainless steel and duplex stainless steel, offer superior corrosion resistance and high strength properties, making them suitable for various applications in oil refineries. These steels can withstand harsh operating conditions, including exposure to corrosive chemicals and high temperatures, ensuring the durability and safety of equipment and infrastructure in the oil refinery industry.

- Q: How does special steel compare to other materials?

- Special steel, also known as alloy steel, exhibits exceptional strength, durability, and resistance to wear and corrosion. When compared to other materials, such as regular steel, aluminum, and plastic, special steel stands out for its superior mechanical properties. Firstly, special steel offers higher tensile strength and hardness, making it ideal for applications requiring heavy-duty performance. Its resistance to deformation and ability to withstand high pressures and temperatures make it suitable for use in industries like aerospace, automotive, and construction. Moreover, special steel possesses excellent wear resistance, making it suitable for applications subject to friction, abrasion, and impact. This property minimizes the need for frequent repairs or replacements, resulting in cost savings and improved efficiency. In terms of corrosion resistance, special steel surpasses regular steel, which is prone to rusting when exposed to moisture or aggressive environments. Its composition includes elements such as chromium, nickel, and molybdenum, which form a protective layer on the surface, preventing corrosion and extending the material's lifespan. Compared to materials like aluminum and plastic, special steel has the advantage of being more robust and less prone to deformation or breakage. While aluminum is lightweight, it lacks the strength and hardness of special steel, limiting its suitability for heavy-duty applications. Plastic, on the other hand, offers lower strength and durability compared to special steel, making it less suitable for demanding tasks. Furthermore, special steel can be easily machined, fabricated, and welded, allowing for versatile applications across various industries. Its flexibility in terms of shaping and forming makes it a preferred choice in the manufacturing of components and structures. Overall, special steel outperforms other materials in terms of strength, durability, wear resistance, corrosion resistance, and versatility. Its exceptional properties make it an essential material in demanding industries where reliability and performance are paramount.

- Q: What are the requirements for special steel used in industrial equipment manufacturing?

- The requirements for special steel used in industrial equipment manufacturing typically include high strength, durability, corrosion resistance, and the ability to withstand high temperatures and pressure. Additionally, the steel should have excellent machinability and weldability to facilitate the manufacturing process. These requirements ensure that the steel can withstand the demanding conditions and provide long-lasting performance in industrial equipment.

- Q: What are the different heat treatment defects in special steel?

- During the heat treatment process of special steel, various defects can occur. Some of the most frequently encountered defects are as follows: 1. Decarburization: This defect arises when the steel's outer layers lose carbon due to exposure to high temperatures in an environment rich in oxygen. The consequence of decarburization is reduced hardness and strength in the treated steel. 2. Quench cracking: Also known as cracking during quenching, this defect emerges when the steel undergoes rapid cooling subsequent to heating. The differential cooling rates can induce internal stresses, resulting in cracks within the material. 3. Distortion: Distortion refers to alterations in the shape or dimensions of the steel during the heat treatment process. It can be caused by uneven heating or cooling, inadequate fixturing, or improper quenching techniques. 4. Soft spots: Soft spots are localized areas of reduced hardness in the treated steel. These spots can occur due to insufficient heating or improper quenching, leading to diminished mechanical strength in those regions. 5. Overheating: Overheating is a defect that occurs when the steel is subjected to excessively high temperatures during the heat treatment process. This can lead to grain growth, reduced toughness, and overall decreased material properties. 6. Case hardening problems: Special steels often undergo case hardening processes, such as carburizing or nitriding, to create a hardened outer layer. However, several defects can arise during these processes, including inadequate or excessive hardening, poor case depth, or uneven distribution of hardness. 7. Residual stresses: Residual stresses are internal stresses that persist in the steel after the heat treatment process. If not properly controlled, these stresses can cause dimensional instability, warping, or even cracking. To prevent or minimize these heat treatment defects, it is crucial to adhere to proper heat treatment procedures. This includes precise temperature control, appropriate cooling rates, and suitable fixturing techniques. Furthermore, the use of high-quality heat treatment equipment, close monitoring of the process, and thorough inspections can aid in detecting and rectifying any potential defects in special steel.

- Q: What is the significance of phosphorus in special steel?

- Phosphorus plays a crucial role in special steel as it enhances its strength, hardness, and machinability. It acts as a grain refiner, reducing the grain size of the steel and improving its toughness. Additionally, phosphorus increases the steel's corrosion resistance and decreases its brittleness, making it more suitable for various industrial applications. Overall, phosphorus is a significant element in special steel, contributing to its overall performance and quality.

- Q: Can special steel be used in the production of consumer goods?

- Yes, special steel can be used in the production of consumer goods. Special steel offers enhanced properties such as high strength, durability, corrosion resistance, and heat resistance, making it suitable for various consumer goods applications. It can be utilized in the manufacturing of kitchen utensils, cutlery, appliances, automotive parts, tools, and more, ensuring improved performance and longevity of these products.

- Q: Can special steel be used in the marine industry?

- Yes, special steel can be used in the marine industry. Special steel, such as stainless steel or corrosion-resistant steel, is often preferred in marine applications due to its high resistance to corrosion from saltwater and harsh environmental conditions. It is commonly used in the construction of ships, offshore structures, and marine equipment to ensure durability and longevity.

- Q: What are the common challenges in forging special steel?

- Common challenges in forging special steel include achieving the desired grain structure, maintaining uniformity and consistency throughout the material, controlling the temperature during the forging process, preventing cracks and defects, and ensuring proper heat treatment for the desired mechanical properties.

- Q: How do alloying elements affect the properties of special steel?

- The properties of special steel are greatly influenced by alloying elements. By incorporating specific elements into the steel composition, it is possible to achieve a variety of desirable characteristics. To begin with, the addition of alloying elements can enhance the steel's strength and hardness. For instance, chromium, nickel, and molybdenum can improve the steel's resistance to deformation and overall toughness. This is especially vital in situations where the steel needs to withstand high temperatures, pressure, or mechanical stress. Furthermore, alloying elements can boost the corrosion resistance of special steel. Elements like chromium, nickel, and copper create a protective oxide layer on the steel's surface, preventing rusting or corrosion. This is of particular importance in industries such as marine, oil and gas, and chemical processing, where exposure to corrosive environments is common. Moreover, alloying elements can influence the steel's weldability, machinability, and heat treatability. For example, manganese and silicon can enhance the weldability of steel, facilitating the joining of different components. On the other hand, vanadium and tungsten can enhance the steel's ability to maintain its hardness even when subjected to high temperatures, making it suitable for applications involving heat treatment. Additionally, alloying elements can affect the electrical and magnetic properties of steel. Elements like nickel and cobalt can improve the steel's magnetic properties, making it suitable for use in electrical transformers or magnetic devices. Conversely, aluminum and titanium can enhance the steel's electrical conductivity, making it ideal for electrical wiring or conductive components. In conclusion, alloying elements have a significant impact on the properties of special steel. They can enhance its strength, hardness, corrosion resistance, weldability, heat treatability, electrical conductivity, and magnetic properties. By carefully selecting and controlling the alloying elements, manufacturers can customize the steel's properties to meet the specific requirements of different industries and applications.

Send your message to us

Hot Rolled Grade ASTM A36_S235JR_SS400 Steel Flat Bar Catalogue

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords