High Quality for Bearing Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200Ton m.t.

- Supply Capability:

- 500Tons per day m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Quality for Bearing Steel

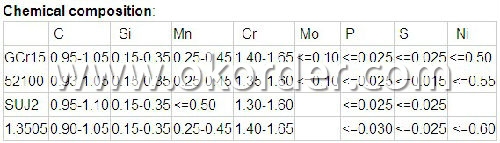

1. Grade: GCr15/SAE52100/EN31/DIN 1.3505/JIS SUJ2

2. Sizes: Diameter 80-1000mm,or as required; Length 500-6000mm,or as required;.

3. Processing: Hot- forged, EAF+LF+VD+Forged+Heat treatment (A,N,Q,T for optional)

4. Heat Treatment:

Soft annealing: heat to 680-720°C, cool slowly.

Hardness after annealing: Max. 241 HB

Hardening: 820 - 850 °C

Normalizing temperature: 840-880°C

Tempering: 540-680°C

5. Surface requirements: Black, grinding, bright, polish

6. Features:

Stable elements, low harmful elements, high-purity steel, evenly carbides, ewer surface defects;

using with wide range of plastic processing, heat treatment with stable quality, high and

evenly hardness, good wear resistance, high strength of contact fatigue; excellent cutting and process ability.

7.

8.Payment terms: T/T or L/C at sight

Usage & Applications of High Quality for Bearing Steel

Our products have been used in all kinds of areas, such as aviation, aerospace, navigation, nuclear, energy, chemical industry, electronic information, petrochemical, automotive, instrument and meter, Communication ,transportation, and medical instruments, etc. Bearing ring,steel rolling mill ,machinery, 100Cr6 bearing steel ball is widely used in high-speed and low-noise bearing, bicycle, motorcycle, automobile, bags, electronics.

Packaging & Delivery of High Quality for Bearing Steel

Mark: Heat No. will be cold stamped and Steel grade, diameter (mm), length (mm), and the manufacturer LOGO and weight (kg) is painted.

Standard seaworthy packing or as customer required

Delivery time: Within 30 days after order is confirmed.

- Q: What grade of iron powder should be used for processing special steel? Are there any other elements on the request? How much are they?

- The main special steel carbon structural steel, carbon tool steel, carbon spring steel, alloy spring steel, alloy structural steel, bearing steel, alloy tool steel, alloy tool steel, high-speed tool steel, stainless steel, heat-resistant steel and high-temperature alloy, precision alloy, gold and other electric heating.

- Q: How does cryogenic treatment affect the toughness of special steel?

- Cryogenic treatment significantly improves the toughness of special steel. It involves subjecting the steel to extremely low temperatures, typically below -150°C, resulting in the transformation of retained austenite into martensite. This process enhances the steel's microstructure, reducing residual stresses and increasing its hardness, wear resistance, and overall toughness. The cryogenic treatment also refines the grain structure, leading to improved mechanical properties and increased resistance to fatigue and cracking.

- Q: What are the main advantages of using special steel in the medical field?

- The main advantages of using special steel in the medical field are its high strength and durability, corrosion resistance, and compatibility with sterilization processes. Special steel can withstand harsh conditions and repetitive use without compromising its integrity, making it ideal for medical devices and surgical instruments. Additionally, its resistance to corrosion ensures a longer lifespan and reduces the risk of contamination. The compatibility with sterilization methods, such as autoclaving, ensures that medical equipment remains safe and sterile for patient use.

- Q: How does special steel contribute to the toughness of products?

- There are several ways in which special steel enhances the toughness of products. Firstly, its high strength and durability are well-known. Specific alloying elements and heat treatment processes are used in its manufacturing, which improve its mechanical properties and make it more resistant to wear and tear. As a result, products made from special steel can withstand heavy loads, impacts, and harsh environments, making them tougher and less prone to breakage. Moreover, special steel possesses excellent corrosion resistance properties. This is achieved by adding specific alloying elements like chromium and nickel, which create a protective layer on the steel's surface, preventing rust and corrosion. The ability to resist corrosion adds to the toughness of the products since they can be used in corrosive environments without experiencing degradation or loss of performance. Furthermore, special steel offers enhanced heat resistance. It can endure high temperatures without compromising its structural integrity or mechanical properties. This is particularly valuable in industries such as aerospace, automotive, and energy, where components are subjected to extreme temperatures. The capacity of special steel to maintain toughness under high heat conditions contributes to the overall reliability and longevity of the products. Additionally, special steel can be customized to meet specific requirements. Manufacturers can tailor the composition and properties of the steel according to the intended application. For instance, various types of special steel alloys are utilized in the production of cutting tools, bearings, and structural components. By selecting the appropriate grade of special steel, manufacturers can optimize the toughness of their products, ensuring they can withstand the intended use and perform reliably. In conclusion, special steel enhances the toughness of products through its high strength, corrosion resistance, heat resistance, and customizability. The distinctive properties of special steel make it an ideal choice for a wide range of applications where toughness and durability are essential factors.

- Q: Is special steel suitable for manufacturing precision components?

- Yes, special steel is indeed suitable for manufacturing precision components. Special steel possesses unique properties such as high strength, wear resistance, and excellent dimensional stability, making it ideal for producing components with precise and intricate designs. Additionally, its superior machinability and ability to withstand extreme conditions further enhance its suitability for manufacturing precision components.

- Q: What are the main factors affecting the heat resistance of special steel?

- The main factors affecting the heat resistance of special steel include its composition, microstructure, and processing techniques. The composition of the steel, particularly the presence of alloying elements such as chromium, nickel, and molybdenum, can greatly influence its ability to withstand high temperatures. Additionally, the microstructure of the steel, which is determined by factors like heat treatment and grain size, plays a significant role in its heat resistance. Finally, the processing techniques used during the manufacturing of the steel, such as forging or casting, can also impact its ability to withstand heat.

- Q: What are the different corrosion protection methods used for special steel?

- To ensure the durability and longevity of special steel, various methods are employed for corrosion protection. These methods encompass: 1. Coatings: The application of diverse coatings, including paint, epoxy, or zinc, creates a protective layer on the steel surface. Such coatings function as barriers, preventing direct contact between moisture, corrosive elements, and the steel. 2. Galvanization: By coating the steel with a layer of zinc through the process of galvanization, a sacrificial barrier is formed wherein the zinc corrodes instead of the steel. Galvanized steel is commonly utilized in outdoor applications such as fences, poles, and roofing. 3. Stainless steel: Special steel can be manufactured using stainless steel, which contains a high percentage of chromium. The presence of chromium results in the formation of a passive layer on the steel's surface, endowing it with excellent corrosion resistance. Stainless steel finds wide usage in industries like construction, food processing, and medical equipment. 4. Cathodic protection: This method involves the creation of an electrical current or the utilization of sacrificial anodes to protect the steel. By introducing a more reactive metal (sacrificial anode) or applying an electrical current, corrosion is minimized as the reactive metal corrodes instead of the steel. 5. Alloying: Modifying the steel's composition by incorporating elements like nickel, molybdenum, or copper can enhance its resistance to corrosion. These alloying elements form a protective layer on the surface, rendering the steel more resistant to rust and other forms of corrosion. 6. Passivation: Passivation is a chemical process that eliminates free iron from the steel's surface, leading to the formation of a protective oxide layer. This layer acts as a barrier against corrosion, augmenting the steel's resistance to rust and other forms of corrosion. 7. Proper maintenance: Regular inspection, cleaning, and maintenance of special steel play a vital role in preventing corrosion. The removal of dirt, debris, and other contaminants from the steel's surface aids in preserving its protective coatings and averting corrosion. It is crucial to select the appropriate corrosion protection method based on the specific application and environmental conditions to ensure the long-term performance and durability of special steel.

- Q: What are the different construction grades of special steel?

- There are several different construction grades of special steel, including but not limited to ASTM A36, ASTM A572, ASTM A514, and ASTM A588. These grades vary in their mechanical properties and are specifically designed to meet different construction requirements, such as strength, durability, or corrosion resistance.

- Q: How does tool steel maintain its hardness at high temperatures?

- Tool steel maintains its hardness at high temperatures primarily due to its high carbon content and the presence of other alloying elements. The carbon in tool steel forms hard and wear-resistant carbides, which help retain hardness even at elevated temperatures. Additionally, alloying elements such as chromium, tungsten, molybdenum, and vanadium contribute to the formation of secondary carbides, which further enhance the steel's resistance to softening and maintain its hardness under high heat conditions.

- Q: How does special steel contribute to the aerospace fastener industry?

- Special steel plays a crucial role in the aerospace fastener industry by providing high strength, durability, and resistance to extreme conditions. Aerospace fasteners are essential components that hold various parts of an aircraft together, ensuring structural integrity and safety during flight. The use of special steel in manufacturing these fasteners allows them to withstand the demanding requirements of the aerospace industry. One of the key contributions of special steel to the aerospace fastener industry is its ability to maintain strength at high temperatures. Aircraft engines operate at extremely high temperatures, and fasteners made from special steel can withstand these conditions without losing their integrity. This is essential for ensuring the reliability and safety of the aircraft, as any failure of the fasteners could lead to catastrophic consequences. In addition to temperature resistance, special steel also offers exceptional strength and corrosion resistance. Aerospace fasteners made from special steel can withstand the tremendous forces and stresses experienced during flight, ensuring that the components remain securely fastened together. Moreover, they are highly resistant to corrosion, which is crucial considering the exposure of aircraft to harsh environmental conditions, including moisture and chemicals. The unique properties of special steel also enable the production of lightweight fasteners without compromising their strength. Weight reduction is a primary concern in the aerospace industry as it directly impacts fuel efficiency and overall performance. By utilizing special steel, manufacturers can design fasteners that are both strong and lightweight, contributing to the overall weight reduction efforts of modern aircraft. Furthermore, special steel allows for the production of fasteners with precise dimensions and tight tolerances. This is essential for achieving a secure fit between components, minimizing vibrations and potential damage caused by movement during flight. The accuracy and reliability of special steel fasteners are crucial for maintaining the structural integrity and safety of the aircraft. In conclusion, special steel significantly contributes to the aerospace fastener industry by providing the necessary strength, durability, temperature resistance, and corrosion resistance needed for aircraft applications. Its unique properties enable the production of lightweight yet robust fasteners, ensuring the structural integrity and safety of modern aircraft. Without special steel, the aerospace industry would face significant challenges in meeting the demanding requirements of aviation.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1990 |

| Annual Output Value | Above US$ 20 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | High; Average |

Send your message to us

High Quality for Bearing Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200Ton m.t.

- Supply Capability:

- 500Tons per day m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords