Horizontal Multistage Water Pump/Industry Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

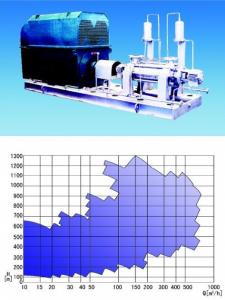

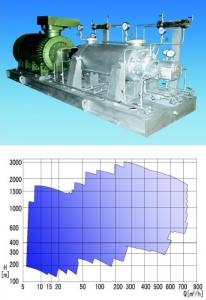

Horizontal Multistage Water Pump/Industry Pump

Introduction of Horizontal Multistage Water Pump/Industry Pump

Single-suction multi-stage sectional-type centrifugal pump is used to transport the pure water containing no solid grains and the liquid with both physical and chemical natures similar to those of pure water, the temperature of the liquid is not over 80°C,suitable for water supply and drainage in mines, factories and cities.

Note: Use an explosion-proof motor when used in a coal well.

This series pump comply with the standards of GB/T3216 and GB/T5657

Features of Horizontal Multistage Water Pump/Industry Pump

a) High efficiency

b) Horizontal structure

c) Multi-stage sectional-type

Applications of Horizontal Multistage Water Pump/Industry Pump

a) Water supply for high building

b) Water supply for city town

c) Heat supply and warm circulation

d) Mining and plant

Technical data of Horizontal Multistage Water Pump/Industry Pump

a) Flow: 25 - 500cbm/h

b) Head: 60 - 1,798m

c) Medium temperature: -20 ~ 80oC

d) Operation pressure: ≤200bar

e) Diameter: 40 - 150mm

FAQ

Q: Are your pumps protected against dry running?

A: No, unprotected centrifugal pumps are not generally designed for dry running. It is important to give us or your dealer as much information as possible about the system in which the pump is used. Inlet pressure, the type of liquid to be pumped, together with relative density, viscosity and temperature, for example, are required in order to allow CNBM to recommend the right pump with the right gaskets for a long operating lifetime.

Q: How can I get trained on CNBM products?

A: Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

Q: Are your pumps cheaper than those of your competitors?

A: CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

Q: Do you have self-priming pumps?

A: Yes, our product portfolio also includes two ranges of self-priming pumps: self-priming electric pumps and self-priming side channel pumps.

Q: Is it really necessary to fit a bleed valve for the boxes?

A: It is always best to have a bleed valve as the gas produced by the fermenting sewage is potentially hazardous.

Q: If I increase the power of the motor, must I also increase the power of the inverter?

A: You must select the size of converter that allows maximum absorption of the electric motor.

- Q: What is the current of the pump when it is started?

- Just started when the pump current is 2-3 times the rated current is normal, so, the power is greater than the pump motor, many small factories in order to survive, the small motor will cut corners, produces motor burning phenomenon, and pump failure caused by load current is increased, and the pump flow rate exceeds the rated flow is a super current. General large water pump is the first to start the water pump, and then open the outlet valve, is to solve the pump just started when the ultra current problems.After excluding pump fault flowmeter check flow is beyond the rated flow, the excess can pumpslittle off flow control valve to reduce the current problems above are not dismantle the motor current of the motor itself over to see how to judge whether the motor has fault.

- Q: what is NPSH for the water pump. Can you anyone explain in details? How can it calculate?

- Net Positive Suction Head Equation

- Q: We have just replced our hot water heater in our camper. When we turn on the water pump we hear it kick on and run. When we turn on a faucet water comes out then slowly goes away untill nothing comes out at all. It has been a year since we used the water tank, so its been full of air. The camper is pretty old, i dont know the specific date though. Could it be low water pressur? any help would be greatly appreciated.

- Check to see if the water pump has a filter on it. Could look like window screen or similar. Junk in that will fill up with pressure and cut the water off. If the pump stops running after a few seconds of flowing, its probably a filter. Once they get to a certain pressure, water valve opened or closed, they shut off to keep from burning up. If the water tank was left with some water in it, moss may have grown. Should flush it with some clorox and water. Check with a local dealer to see how much.

- Q: the impeller on my calpump pw1200 water pump will not turn. what is the problem? and how do you fix it

- CLR soak. Remove the calcium and lime from the tap water use. I would use a 50/50 solution in the inlet and give it 30 min then plug it back in with the in and out in a bucket with the 50/50 mix until it runs like new.

- Q: I live in a house that uses a pump to push water from a tank to the bathroom and kitchen. It has a sensor that detects if water is flowing and pushes it much harder. Recently, it has been pushing the water for a second or less then it completely stops for a while. It's like a pulse of water then nothing. Can anyone give me feedback on what is wrong here? Thank you.

- from okorder :Self-priming pump working principle is: the pump before you start in the pump shell filled with water (or) from the water in the pump housing.Start after high-speed rotating impeller flow to the vortex in the impeller, shell, then the entry form the vacuum, the inlet non-return door open, within the air into the pump suction tube and the impeller, to arrive at the outer edge.Self-priming pump is a self-priming centrifugal pump, it has compact structure, convenient operation, stable operation, easy maintenance, high efficiency, long service life, and have strong self-priming capacity, etc.Line does not need to install the bottom valve, only to ensure storage in pump body before work are quantitative liquid.Pump after the normal starting, impeller liquid of suction chamber and inlet line of air suction, and can completely mixed within the impeller, the function of centrifugal force, and liquid with gas to the vortex flow volume outside edge, the impeller has a certain thickness is formed on the outer edge of the white foam belt and high-speed rotating liquid ring.Gas-liquid mixture into the gas-liquid separation chamber through diffusion tube.At this time, due to the flow rate suddenly drops, lighter gas is separated from the mixture of liquid and gas through the pump body spit continues to rise.After degassing of liquid to liquid storage chamber, and the reflux hole again into the impeller, and impeller with inhalation of gases from the inlet line again mix, flow under the action of the high-speed rotating impeller and the impeller outer edge....As the process cycle, decreasing the air in the suction line, until all gas absorption, complete the self-priming process, pump put into normal operation. What you said phenomenon should be pipeline leak, which leads to the self-priming pump process is repeated.

- Q: Does anyone know where to find small A/C powered submersible pumps, that operate at 20-25 psi? I can only find D/C pumps for ship use.I need one for running humidifiers and misters for large terrariums

- Gonna need more info for this one, start with the usage requirements for the equipment you are supplying. That should give you something to talk about with the local sources. The size of the terrariums and the amount of water in each one, the height that you want to lift the water is another factor to be considered. Be sure to include the diameter of tubing to be used and any special features, fountains, misters, etc. Good Luck

- Q: This only happens while I am running water. I can hear the pressure switch clicking on and off the whole time I am doing dishes, laundry, ... Since it is only when the water is running I believe that means it is not a leak. I changed the check valve and that did not fix the problem. I checked the pressure in the tank and it seemed to be around the 20/40 mark. Any other ideas anyone?Thanks.

- It sounds like the bladder in your pressure tank has ruptured.

- Q: For a Dodge Ram 1500 pick-up. Not taking it to a mechanic.Already got the new pump. Got part of the engine off.Dont exactly have the right tools to make the job go fast but would like some tips on how to make it go faster..

- If you've got the fan off you have the hardest part done on that vehicle,follow the manuals and line the parts up as you remove them.Be sure to put the bolts with the part they belong to and install them in the reverse order you took them off.

- Q: My friend wants to buy a 90's somethin dodge avenger.( not sure what year) and the guy says the water pump is bad. Does the car have to be re timed when u replace the water pump?

- There is no connection between the water pump and the timing. Timing is a function of the engine ignition system, water pumps are part of the cooling system. There is no relationship. The water pump is driven by the belt that drives all the other engine accessories. Changing a water pump does not in any way effect timing.

- Q: My well is 58 meters deep, the water level is 20 meters, the water level has not been measured. What's the maximum water pump I should choose?

- First, determine the size of the electrical well and then the depth. Is it water injection or pumping?The pressure of water injection pump is much higher. If you pump water, it depends on how much water you need every hour Plus you enter the water depth of +10 meters, you can basically a good selection.

Send your message to us

Horizontal Multistage Water Pump/Industry Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords