Horizontal Multistage Designed Stainless Steel Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Horizontal Multistage Designed Stainless Steel Pump.

1>Horizontal multistage stamping welding impeller and diffuser,three different type of choice.

2>Single phase motor up to 2.2kw,Class F and IP55 motor is standard.

3>Standard supply for liquid temperature up to 70 degree centigrade,high temperature pump are available on request.

2. Application for the Horizontal Multistage Designed Stainless Steel Pump.

1>cooling water system

2>agriculture

3>domestic water supply

4>general industrial services

5>washing

6>enviroment protection

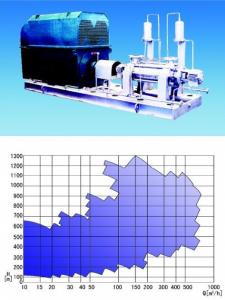

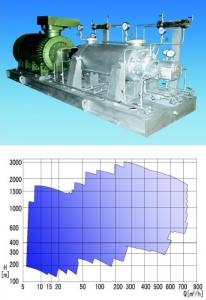

3. Performance range for Horizontal Multistage Designed Stainless Steel Pump.

capacity: Q up to 32m3/h

head H up to 110 degree centigrade

speed: n 2900rpm or 3500rpm

power: P up to 55kw *2

4. Standard material of Horizontal Multistage Designed Stainless Steel Pump.

All the parts contact with liquid made of 304 stainless steel on request.The pump head and suction & discharge can be made of cast iron on request too.

5. RFQ

1> What's the difference for CHL and CHLF(T) type?

CHL pumps have an inlet and outlet chamber which is made by stainless steel. CHLF(T) is just the section type.

2> Do you have any variable motor for these pumps?

Yes, we have. For the variable motor, the frequence can be changed as the customers' request. If the range is between 30~50Hz, the fan can be just connected with the shaft. And if the frequency is below 30Hz, then the fan has to have another separated power. The variable speed motor would be used for solar energy or some other similar situation with the unstable power.

3> How about the Delivery time?

Actually, this would be depending on the quantity. If it is just small order, 1 week would be fine. For bigger quantity, the delivery would be also less then 20 days. But for the varible speed ones, it will be taking some more time, normally it will be more than a month.

- Q: If you use an ordinary 15W submersible pump, put it in the tank, if the leakage, the fish will hang it?

- Submersible pump even if it really leakage, it will not cause the fish electric shock. The so-called leakage is the submersible pump wire or shell broken, live parts and water contact, the most extreme test is a fire line directly into the fish tank

- Q: The distance from the pump button to the ground

- Yellow warning pop-up, indicating that the fire control room has issued alarm information, fire alarm controller (commonly known as the alarm host)

- Q: What are the basic technical parameters of the pump?

- The basic parameters of the pump, the basic parameters of the main performance parameters of pump are the following: first, water pump flow Q flow is the amount of liquid in the pump unit time delivery out (volume or quality). The volume of flow with Q that the unit is: m3/s, m3/h, l/s and so on. The quality of flow unit is expressed in Qm. T/h, kg/s and so on. The relationship between mass flow and volume flow is Qm= P Q density in P - liquid (kg/m3, t/m3), room temperature water P =1000kg/m3.

- Q: How many kilograms of water pump are there in the automatic washing machine on the market?

- High pressure pump pressure can reach 4--8kg, flow 5 liters, work current 4 or so.

- Q: Rules for operation of centrifugal pumps

- 3, start the pump, wait until the speed reaches the normal speed, slowly open the outlet valve, observe the ammeter at the same time, and control the current in the rated current range of the motor.4, the operation requires smooth operation of water pumps, no abnormal noise, no pressure fluctuations. The abnormal situation should be stopped in time.

- Q: What should be used to pay attention to the use of mechanical pumps?

- There are many kinds of pumps, such as centrifugal pumps, piston pumps, diaphragm pumps, vane pumps, gear pumps, etc.

- Q: What are the conditions required for hydraulic pumps to complete oil absorption and compression?

- Volume conditions: oil absorption cavity from small to large, complete oil absorption, oil pressure chamber has become smaller, complete pressure oil.Sealing conditions: the hydraulic pump itself should have good sealing

- Q: How many concrete pump tube diameter

- High pressure is the outer diameter is Phi 140 Type 150 type low pressure pipeline; pipe diameter is Phi 159 pipeline, high pressure pipeline diameter is phi 168.

- Q: Why can't the centrifugal pump pump the vacuum?

- Running process: depending on the centrifugal pressure of the liquid in the impeller, the liquid is sucked into the liquid, and the liquid in the pump shell has the conversion of the energy form, so that the fluid can obtain the mechanical energy mainly with the static pressure.The characteristics of the system: the suction diameter than out of large diameter, the general valve installed.

- Q: Types and differences of pumps

- (I) volumetric typeClassification reciprocating rotary typeThe basic principle of reciprocating action by the piston in the cylinder in the cylinder volume changes again, with the suction and discharge of fluid in the shell or the rotor rotating member rotates, the volume of work between rotor and casing changes to the suction and discharge fluid, such as piston pump gear pump, screw pump(two) blade type;The main structure of vane pumps and fans is rotary, bladed impellers and stationary housings that rotate fluid through the impeller to do work, thereby enabling fluids to obtain energy

Send your message to us

Horizontal Multistage Designed Stainless Steel Pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 2000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches