Horizontal Multistage Water Pump for Pump Station

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Horizontal Multistage Water Pump for Pump Station

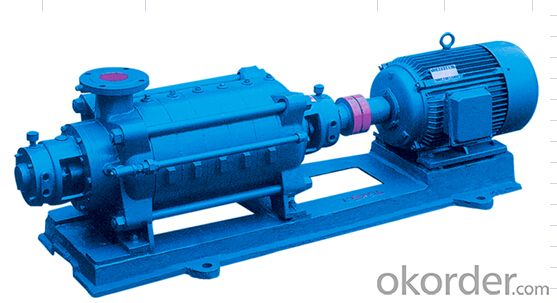

1.Structure of Horizontal Multistage Water Pump for Pump Station

The high presuure boiler feed multistage water pump is a horizontal multistage centrifugal pump and suitable for transporting pure water,both ends of it are supported,the casing portion is a senctional form,it is connected and actuated by motor via a resilient clutch.From the driven direction,the pump rotated direction is clockwise.

2.Main Features of Horizontal Multistage Water Pump for Pump Station

• High Effiency

•Low noise

•Long life, OEM and ODM are welcomed.

3.Horizontal Multistage Water Pump for Pump StationImages

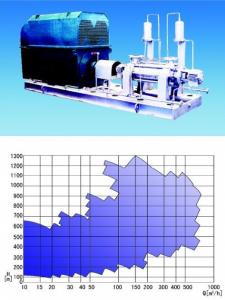

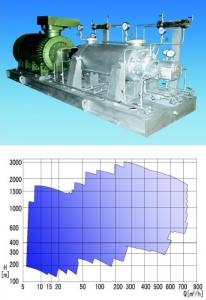

4.Horizontal Multistage Water Pump for Pump Station Specification

Material |

Cast iron and as customer's request |

Temperature |

Less than 150°C |

Flow rate | 3.75-300m3/h |

Head | 75-1000m |

Medium temperature | 0 ~170°C |

Operation pressure | ≤40 bars |

5.FAQ

①What is the applications?

Power Station,Industry Water Supply

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance. Normally, We have 1 year warranty.

- Q: What is a water pump coupling device?

- The water pump coupling device comprises a coupler, a coupling flange, a guide rod and an upper fixing plate, wherein the contact surface of the coupling base and the coupling slide plate is provided with an annular groove, and a soft sealing gasket is tightly fixed on the groove. By adopting the structure, the coupling contact surface of the coupling slide plate and the coupling base is sealed firmly by an annular sealing groove

- Q: Why should the pump be closed when the centrifugal pump is started?

- On the other hand, the water on the pipe of the inlet pipe of the pump is stationary before the pump is opened, such as the sudden acceleration, and the water behind it can not keep up, which will cause the pressure of the inlet to drop suddenly and vaporize the water, and the centrifugal pump will be evacuated. (because of the centrifugal pump is rotating centrifugal force generated by the pump, leaf water and steam driven (gas) quality is very light, according to F= Ma, the centrifugal force is small, the pump can not be water sent).

- Q: The function of centrifugal pump

- 6. Stuffing box mainly consists of packing, water seal ring, stuffing box, packing gland and water seal pipe. The function of the stuffing box is mainly to close the gap between the pump shell and the pump shaft. The water in the pump is not allowed to flow outside and the outside air is not allowed to enter the pump. Always keep the vacuum in the pump! When the pump shaft and packing friction heat, it is necessary to rely on water seal to control water into the water ring, so that the filler cooling! Keep the pump running properly. Therefore, in the water pump running inspection process, the stuffing box inspection is to pay special attention to! In the operation of about 600 hours, it is necessary to replace the packing.

- Q: What does the pump mortar do?

- Concrete pump before the need to transport water and pump pump material, dredge pipeline. In accordance with the technical specification for concrete pumping construction (JGJ/T10 - 1995), pumping concrete, pump mortar generally use cement slurry

- Q: What does "anti pump" mean in pump operation?

- The working process of the main oil cylinder pushing back and forth against the pump when the S valve (C valve or valve or gate valve skirt) reverse swing, so the piston suction concrete cylinder is in the ash conveying pipe is exactly opposite is the pump suction pump (hopper is concrete and push into the hopper, the desizing)

- Q: I would like to ask, constant pressure pump set pressure 20Mpa, the actual load is 15Mpa, then the constant pressure pump outlet pressure? If it is 20Mpa, then where is the loss of 5Mpa? If 15Mpa, the constant pressure pump 20Mpa how to understand? In addition, the constant pressure pump pressure is defined when the flow began to reduce the point, or a sharp drop in flow after the point?

- Constant pressure pump is pressure maintained at the set pressure, flow control valve according to the order, there is pressure to set, after the pump displacement is reduced, as for how to reduce emissions, to see how much you need to flow.

- Q: Why can't the inlet of centrifugal pump be negative pressure?

- Can be negative pressure ah, the negative pressure here refers to the pressure is less than the atmospheric pressure, but the pressure can not be too low, to prevent water vapor below the saturated vapor pressure, so that water vaporization, cavitation phenomenon, the centrifugal pump will be considered.

- Q: What are the application areas of pumps?

- Water pump has different uses, different transmission liquid medium, different flow, lift range, therefore, its structure form is not the same, the material is also different, summed up, can be roughly divided into:

- Q: What is the working pressure of the hydraulic pump in the hydraulic transmission system?

- The choice of pressure depends on the size of the load and the type of equipment. Consideration shall also be given to the assembly space, the economic conditions and the availability of components for the actuators.In the case of a certain load, low working pressure, is bound to increase the structure size of the actuator on some devices, the size must be limited, from the perspective of material consumption is not the economy; on the other hand, the pressure to choose too large, the pump, cylinder, valve and other components of the material, sealing and manufacturing accuracy requirements very high, must raise the cost of equipment.

- Q: How many pumps does the 80cm tank use?

- For example, you are 80 cm tank, assuming you are 40 cm wide, the water surface is also 40 cm, then the final count by 80X40X40=128000 cubic centimeter, that is, 128000 ml.

Send your message to us

Horizontal Multistage Water Pump for Pump Station

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches