HN Series Canned Motor Pump with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

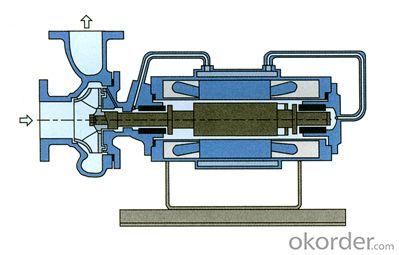

Production Overview of HN Series Canned Motor Pump

The canned motor pump body connects directly with motor front flange, and can convey the medium low temperature fluid with no granule be zero leakage.

The Canned Pump is a centrifugal pump, close coupled to a Canned Motor in such a way that

there is no dynamic shaft seal, no couplings and no ball bearings. The motor is cooled by the

pumped liquid and the sleeve type.

Bearings are lubricated by the same liquid. This eliminates the need for external lubrication.

The stator of the driving motor, which is usually three phase squirrel cage induction motor,

which is hermetically contained in a stator containment that consist of an external frame tube,

out board & inboard end plates and the internal cylinder liner. The rotor which is welded on

the shaft, is also encapsulated with a non magnetic liner. Both stator liner (Stator Can) and

rotor liner (rotor can) are seal welded at both ends, and does not allow any part of the motor to be

exposed to external environment or internal pumped liquid.

Featurers of HN Series Canned Motor Pump

1) No shaft seals, no leak paths

2) No buffer pots to maintain

3) No coupling or alignment problems

4) Primary leak containment shell

5) Proven bearing monitor detects bearing wear before primary leak containment shell is contacted by the rotor

6) Dry stator design and sealed junction box terminal plate

7) Controlled bearing enviroment, conservation bearing design and hydraulic thrust balancing,extended bearing life

FAQ

Q: How can I get trained on CNBM products?

A: Yes, we provide training courses in our factory (products, general and specific pump technology, hydraulics, and practical applications). Please consult your sales manager or get in touch with our headquarters for more information.

Q: Are your pumps cheaper than those of your competitors?

A: CNBM aims to give its customers the highest standards of quality and service and delivery times, all at a reasonable price.

Q: Do you have self-priming pumps?

A: Yes, our product portfolio also includes two ranges of self-priming pumps: self-priming electric pumps and self-priming side channel pumps.

Q: Is it really necessary to fit a bleed valve for the boxes?

A: It is always best to have a bleed valve as the gas produced by the fermenting sewage is potentially hazardous.

Q: If I increase the power of the motor, must I also increase the power of the inverter?

A: You must select the size of converter that allows maximum absorption of the electric motor.

Q: Do you have pumps with grinders?

A: Yes, the WQ models.

- Q: how do get the tub off the washine machine to fix the water pump?

- Can you tell us what brand? They do NOT make them all the same either in placement, access, or attachment.... So to be able to help you properly, we need MORE INFO, PLEASE!!!!

- Q: Pump frequent start will reduce the service life, I ask what kind of frequency is called frequent start?

- Personally think that the quality of different motors have different effects on the motor, you can try, try a minute it ruined his frequency is a / S

- Q: Water pump is STILL constantly running! Since this past thursday, we did:new check valvenew pressure controlnew foot valve (well)well is not dryprime, air pressure are finewe have above ground pump in the basement. we called a plumber and he could do nothing! we have water and pump/tank and everything seem working fine.But the pump is on and off every 30 seconds - 1 minute. It is so annoying and out of ideas what could be wrong.My husband think it could be the tank and suggested that we replace it. But the plumber didn't say anything about the tank. And it is not too old.Do you think it is the tank and we need to replace it? If so, we will do it on this Sunday morning even though it might cost extra charge! please help!!!

- Reading through what you have replaced about the only thing it could be is you have a hole in the supply line somewhere. If the tank needed replacement, when there is no draw on the system, like when you get a drink of water, there will be no cycling of the pump. In other words if there is no spigot on then there must be a leak somewhere.

- Q: antifreeze leaking from the water pump. antifreeze wont stay in car, car overheating. 96 chevy cavalier. 2.4

- Unfortunately, this usually requires a new pump. It's possible (but unlikely) that the gasket is leaking - more likely, the seal around the pulley shaft is the problem. Replacement is the only option. Usually, this is done at the same time as the timing belt - has this been done yet? If it was done before you got the car, its possible they tried to save a few bucks by skipping the water pump. This is usually a bad move - the pump almost always wears out at about the same time - but it is cheaper, if they were planning on getting rid of the car soon. And since one usually needs to be removed to access the other...you get the idea. Good luck!

- Q: is there a surface water pump that can pump water from a 1000 foot well?

- If what you mean with surface water pumps are those pumps mounted on the ground to distinguish them from submersible pumps , yes there are surface pumps that can pump water from a 1000 ft well. These are the so called jet pumps or deep well pumps wherein part of the output water is returned back to the bottom of the well pipe through the space between the outer pipe casing and the inner pipe and passed through a venturi opening to create an upward water jet which will push more water upward.

- Q: I could get a 1994 Camaro, v6, no rust, automatic, excellent condition for $1200. THe ony thing is that it needs a water pump. Is it worth the buy? How much other damage could have been done with the water pump damaged? and how hard is it to replace the water pump?

- Tell them you'll give him a thousand and buy it. Check the coolant bottle and look for sludge. Check oil for milkshake looking oil. These motors are known for bad intake and head gaskets and that is not as easy as a water pump.

- Q: My 93 Ford t-bird over heats and i really don't know what could be the problem, the radiator is working fine, and also the fan and the thermostat, i don't think is a head gasket because the oil looks alright with no contamination and there is no steam coming from the exhaust im beginning to suspect the water pump but the weep hole is not leaking. So does a water pump MUST leak from the weep hole if it is bad, or it could be bad and not leak? thanks in advance...

- How To Test Water Pump

- Q: my pump went out and i can't afford to have it fixed at a shop.

- then buy a new one and get your self some tools and a repair manual at autoparts store not much to it once you see what it looks like you start removing parts that are in way til you can take it off clean the old gasket off well and but some blue selicone put on new gasket and put on new pump tighten it put back on all the parts you remove fill radiator start check for leaks should be able to do it on the weekend about three to four hours or lless... any of these will help all about the same as the other but it will give you a better ideal of how to do it and your sure to learn more about your car so doing it would be best not only you learn but you save money too... not hard to replace most parts hard part is knowing what is wrong to replace it so you got the hard part done knowing what is wrong

- Q: Engine problem 1999 Nissan Sentra 4 cyl Front Wheel Drive Automatic 165000 miles ---------------------------------------------------------------- I have a leaking water pump that has to be replaced. I am calling around getting prices and some people tell me that I have to do the timing chain at the same time and that will be a great deal more money. Can I just replace the water pump? It seems that the water pump only will be about 200.00 but both could be 500.00. Please help

- Nissan Almera Water Pump

- Q: overheating.it has a new thermostat,radiator is clean.temp stays normal during idle,rises when i start to drive.ac is off when this happens.its a 4.7 dodge durango.can water pump simplyquot;go badquot;without ever leaking?

- if it,s circulating then the water pump is doing its job. does the fan kick on? maybe 1 of the hoses is closing up when your driving. usually when the bearing goes bad in the pump it takes the seal out too and starts to leak.

Send your message to us

HN Series Canned Motor Pump with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords