High quality precast concrete bridge beam segmental box girder steel formwork

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 5000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Segmental box girder steel formwork

Product Introduction:

With the rapid development of urban rail transit project, the Segmental box girder steel formwork is widely used in viaduct road. It have the advantages of noise-reduction good effect, low building height, high space utilization and good appearance.

With the progress of technology, construction method changes from cast-in-place to precast hoisting. Use double crane lifting or gantry crane lifting to hoisting the Segmental box girder steel formwork .

Specification:

Precast U-Beam formwork structure: outer side formwork, inner formwork, bottom formwork, support lead screw, JACK, work platform, Vibrator, crawling ladder, blanking plate etc.

Main products covers:

U-shaped beam

Segmental beam

Climb mold

Integrated pipe gallery

Automatic Prefabrication culvert

Shaped pier

T-beam

Alien template

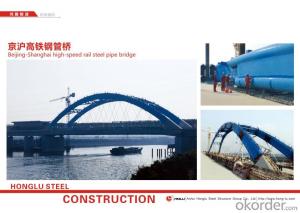

Applied formwork Project:

Our products capacity:

More than 3 state grade certificates

More than 40 patents

More than 10 series main products

More than 10 government and project awards

WORKSHOP & EQUIPMENT:

- Q: Is there a beam plate template that is used to calculate the engineering quantity of the beam formwork or the engineering quantity of the beam and the plate? Urgent thank you

- If you read the instructions in the quota, it will be fruitful

- Q: How to put the beam formwork in concrete structure

- When the carpenter die down from the ceiling! To determine! But you need to check it regularly! Not everyone does it by the rules!

- Q: The calculation of formwork engineering quantity of ground beam needs to calculate the bottom of beam

- The ground beam (patand) agreement is commonly known as the foundation beam, which has the characteristics of closed, and the structure of the column into a seismic system,

- Q: Remove the larger span of the beam pillar template why should be removed from the middle to the two ends

- Remove from the ends of beams began to load, is Liang Hezhu nodes under pure shear, a shear deformation from the middle split beam gradually remove support, after the load is gradually increased, the shear in the support under the protection of gradually increasing load, small impact.

- Q: Should not be on the front and back of the four sides of the template? Why is the width of the beam length multiplied by the beam surface? Isn't that the three face?

- Only the bottom surface of the beam and two sides of the template, there is no need to shop template.

- Q: Why is Changshi beam, but also computing to the side or side column beam?How to deduct the overlap area between beam and plate, column and wall, wall and wall

- Cross beam and beam cross section is not a template overlap

- Q: There are times when the beam is not to deduct the secondary beam on the main part of the beam?

- The general situation is calculated according to the contact area between the concrete and the template

- Q: The section size of the beam is 200 x 400 the size of the board is 4500 x 4000 plate thickness of the formula for 120 - a rookie

- The side plate of the plate is the circumference of the plate (minus the protruding part of the column) multiplied by the thickness of the plate 0.1m.Beam slab:Plate beam T beam box girder is divided into cast in place PC box girder and steel box girderBeam type structural member composed of steel plates. The basic section is I-shaped, upper and lower transverse wing plate is vertical plate, the middle name web. Some plates are welded with reinforcing ribs. According to the combination method, it can be divided into welding plate beam, high strength bolt plate beam and dissimilar steel plate beam. Reinforced concrete slab beam.

- Q: For example, the 0.14 long girder thick 400x600 26 how to calculate the amount of engineering template

- Calculating the area of template according to the contact surface

- Q: How to control the elevation of the beam bottom and the axis position

- Above the control points on the scaffold steel pipe before supporting formwork

Send your message to us

High quality precast concrete bridge beam segmental box girder steel formwork

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 5000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords