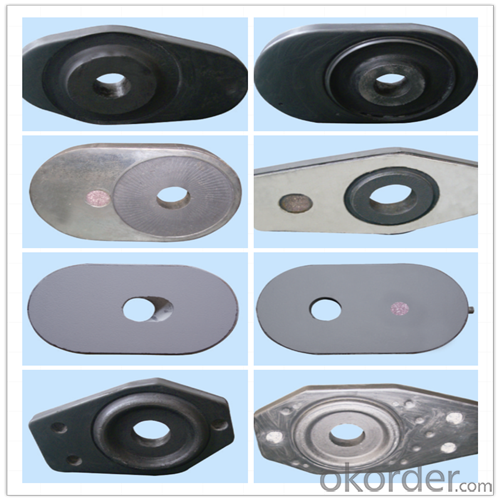

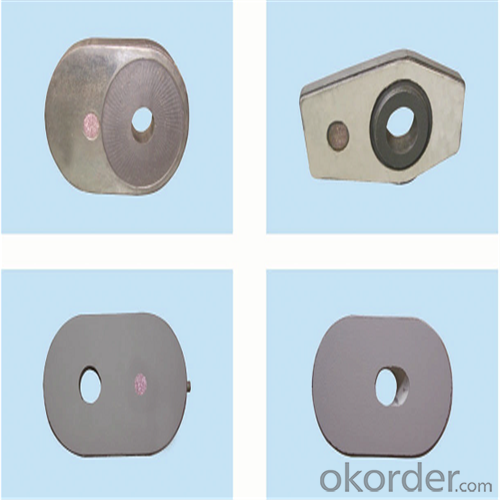

Monolithic Refractories High Performance & Temperature Ladle Slide Gate for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Performance Refractory Ladle Slide Gate

| Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Alumina Block |

| SiO2 Content (%): | N/A | Al2O3 Content (%): | 80-90% | MgO Content (%): | N/A |

| CaO Content (%): | N/A | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | N/A |

| SiC Content (%): | N/A | Model Number: | CS80 | Brand Name: | |

| Product name: | High performance refractory ladle slide gate | Model No.: | cs80 | Brand name: | CMAX |

| Quality: | Al-C or Al-Zr-C | Service life: | 4-6 heats | Apparent porosity: | 7% Max |

| Bulk density:: | 3.1 MIN | C.C.S: | 120MPA | MOQ: | 100 pcs for trial |

| Delivery time: | 60 working days upon receipt of deposit |

Packaging & Delivery

| Packaging Details: | Inner carton packing, outer wooden case suitable for long term sea shipping |

| Delivery Detail: | three months working days upon receipt of deposit |

Specifications

Surface flatness less than 0.05mm

High mechanical strength

Erosion resistance

Oxidation resistance

Thermal shock stability

Using the raw materials of tabular alumina, zirconia-corundum, carbon and other high-grade additives, after sintering to obtain characteristics of oxidation resistance, scour strength, erosion resistance, thermal shock resistance, shape stable and long service life, made our products the preferred materials for the large and medium-sized steel ladle, refining ladle, series of alloy steel ladle, and tundish. Our high performance sintering sliding gates include alumina carbon , Al2O3-ZrO2-C, etc, can meet the needs of different steel grade.

General Chemical Analysis for refractory ladle slide gate :

slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Alumina -Zirconia-Carbon material

| Al-Zr-C Material | |||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 85 | 3 | 5 | 7 | 3.1 | 120 |

| 85 | 3 | 4 | 7 | 3.1 | 120 |

Composite type: Al-Zr-C for working line, outer Al-C material

| Al-Zr-C & Al-C Material | ||||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S | |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) | |

| Inner side (Working face) | 85 | 3 | 4 | 7 | 3.1 | 120 |

| Outside | 90 | 3 | 0 | 9 | 3 | |

Other Products

About us

Sample is on your request.

Welcome to visit our factory~

- Q: How do monolithic refractories impact the overall productivity of iron and steel operations?

- Monolithic refractories play a crucial role in enhancing the overall productivity of iron and steel operations. These refractories are specially designed to withstand extreme temperatures, chemical reactions, and mechanical stress that occur during the production process. One significant impact of monolithic refractories on productivity is their ability to reduce downtime and increase operational efficiency. The high thermal conductivity and resistance to thermal shock of these refractories enable them to maintain stable temperatures within the furnace, preventing sudden temperature fluctuations that can cause equipment failure and production delays. This, in turn, ensures a continuous and uninterrupted production process, leading to increased productivity. Moreover, monolithic refractories offer superior corrosion resistance, preventing the erosion and degradation of furnace linings. This resistance to chemical attacks from molten metals and slag helps prolong the lifespan of the refractory lining, reducing the frequency of repairs and replacements. Consequently, the reduced maintenance requirements translate into less downtime and higher productivity for iron and steel operations. Additionally, monolithic refractories facilitate faster installation and repair processes compared to traditional brick refractories. Their fluid-like nature allows for easy application and shaping, resulting in shorter installation and curing times. This quick turnaround time minimizes production interruptions during repairs or maintenance, further enhancing overall productivity. Furthermore, the use of monolithic refractories can optimize energy consumption in iron and steel operations. Their excellent insulation properties help retain heat within the furnace, reducing heat loss and energy waste. This leads to improved energy efficiency and cost savings, contributing to increased productivity and profitability. In summary, monolithic refractories have a significant impact on the overall productivity of iron and steel operations. Their ability to withstand extreme conditions, reduce downtime, resist corrosion, facilitate quick repairs, and optimize energy consumption all contribute to improved efficiency and productivity in the industry.

- Q: What are the challenges in recycling monolithic refractories?

- Recycling monolithic refractories presents several challenges that complicate the process compared to other materials. To begin with, the exceptional resistance of monolithic refractories to high temperatures and harsh conditions makes them difficult to break down and separate. Specialized techniques and equipment are required for this purpose. Furthermore, monolithic refractories often contain various additives and binders, such as clay, cement, and other organic compounds. These additional substances add complexity to the recycling process, as they may need to be removed or separated from the refractory material before effective recycling can take place. Moreover, monolithic refractories are prone to contamination during their service life, with metal oxides, slag, and impurities being common culprits. These contaminants can affect the quality and properties of the recycled refractory material, necessitating thorough cleaning and purification procedures. Additionally, the logistics involved in collecting and transporting monolithic refractories for recycling can be challenging. Given that refractories are typically used in large quantities in industrial settings, their removal and transportation can be costly and time-consuming. Furthermore, finding suitable recycling facilities equipped with the necessary expertise and equipment to handle monolithic refractories can be limited, particularly in certain regions. Lastly, economic factors contribute to the challenges of recycling monolithic refractories. The financial viability of recycling and processing these refractories may not always justify the cost compared to using new materials. Consequently, companies may be discouraged from investing in recycling programs, leading to lower demand for recycled refractory materials. In summary, the challenges associated with recycling monolithic refractories primarily arise from their durability, complex composition, contamination, logistics, and economic considerations. Nonetheless, with technological advancements and increased awareness of the environmental benefits of recycling, these challenges can be overcome, promoting the sustainable reuse of refractory materials.

- Q: How do monolithic refractories contribute to the overall efficiency of ladle slagging operations?

- Monolithic refractories play a crucial role in improving the overall efficiency of ladle slagging operations. Ladle slagging is a process that involves the removal of impurities from molten metal in a ladle before it is poured into molds or further processed. One of the key contributions of monolithic refractories is their ability to withstand high temperatures, which is essential in ladle slagging operations. The refractory lining of the ladle needs to be able to endure the extreme heat generated by the molten metal and slag, as well as the chemical reactions occurring during the process. Monolithic refractories, with their high thermal stability, prevent the lining from cracking or deteriorating, thus ensuring the integrity of the ladle and maintaining its efficiency. Additionally, monolithic refractories offer excellent resistance to chemical erosion and corrosion. During the ladle slagging process, the molten metal and slag can contain various impurities and aggressive chemicals, such as sulfur, phosphorus, and other oxides. These substances can attack and degrade the lining of the ladle, compromising its efficiency. However, monolithic refractories are designed to resist these chemical attacks, thereby extending the lifespan of the ladle and reducing the need for frequent repairs or replacements. Moreover, monolithic refractories provide good thermal insulation properties. Ladle slagging operations require precise temperature control to ensure the desired chemical reactions and efficient removal of impurities. The thermal insulation offered by monolithic refractories helps to maintain a consistent temperature within the ladle, preventing heat loss and allowing for optimized slagging conditions. This insulation also minimizes energy consumption and improves the overall energy efficiency of the ladle slagging process. In conclusion, monolithic refractories contribute significantly to the overall efficiency of ladle slagging operations. Their ability to withstand high temperatures, resist chemical erosion, and provide thermal insulation ensures the integrity and longevity of the ladle. By reducing the need for frequent repairs and allowing for precise temperature control, monolithic refractories optimize the slagging process, leading to improved productivity and cost-effectiveness.

- Q: What types of monolithic refractories are commonly used in the iron and steel industry?

- In the iron and steel industry, several types of monolithic refractories are commonly used due to their high resistance to extreme temperatures and mechanical stresses. These refractories are essential for lining furnaces, ladles, and other equipment used in the production of iron and steel. One commonly used monolithic refractory in this industry is castable refractory. It is a mixture of refractory aggregates, binders, and additives that can be poured or cast into various shapes and sizes. Castable refractories are versatile and can be easily installed, making them suitable for lining large furnaces and ladles. They offer good thermal insulation and excellent resistance to thermal shocks. Another type of monolithic refractory used in the iron and steel industry is plastic refractory. It consists of a high-alumina refractory aggregate mixed with a bonding agent, usually clay. Plastic refractories have a high plasticity and can be easily shaped by hand or with a trowel. They are commonly used for repairs and patching in furnaces and ladles. Ramming refractories are also commonly employed in the iron and steel industry. These refractories are made of granular refractory materials mixed with a binder. They are installed by ramming the mixture into the desired shape using a pneumatic hammer or manual ramming tools. Ramming refractories offer high resistance to abrasion and erosion, making them suitable for lining the bottoms of furnaces and other areas subjected to intense mechanical wear. Lastly, gunning refractories are frequently used in the iron and steel industry. Gunning refractories are made of fine refractory powders mixed with water or a bonding agent. They are applied using a gunning machine, which propels the refractory material onto the surface to be lined. Gunning refractories are commonly used for repairing and maintaining the linings of ladles, tundishes, and other equipment. Overall, the iron and steel industry relies on a variety of monolithic refractories such as castables, plastics, rammings, and gunnings to ensure the reliable and efficient operation of their equipment in high-temperature environments. These refractories provide excellent thermal insulation, resistance to thermal shocks, and mechanical strength essential for the production of iron and steel.

- Q: How long is the lifespan of monolithic refractories in iron and steel applications?

- The lifespan of monolithic refractories in iron and steel applications can vary depending on several factors such as the specific type of refractory material used, the operating conditions, and the maintenance practices. However, on average, monolithic refractories in iron and steel applications can last anywhere from a few months to several years.

- Q: How do monolithic refractories contribute to the overall efficiency of steel ladle operations?

- Monolithic refractories play a crucial role in enhancing the overall efficiency of steel ladle operations. These refractories are engineered materials that are installed as a single, unbroken structure within the ladle. They offer numerous benefits that directly contribute to the efficiency of the steel ladle operations. Firstly, monolithic refractories are known for their excellent thermal insulation properties. They have low thermal conductivity, which means they can effectively retain and contain heat within the ladle. This insulation property helps in maintaining the desired temperature of the molten steel, preventing heat loss during transportation and reducing the need for frequent reheating. By minimizing heat loss, monolithic refractories enable more efficient use of energy resources, resulting in cost savings and improved productivity. Additionally, monolithic refractories exhibit high refractoriness, which refers to their ability to withstand high temperatures without losing their structural integrity. This characteristic is vital in steel ladle operations, as the ladles are exposed to extreme temperatures during the steelmaking process. The high refractoriness of monolithic refractories ensures that they can withstand the intense heat and prevent any damage or failure of the ladle lining. This durability translates into reduced downtime and maintenance requirements, leading to increased operational efficiency. Moreover, monolithic refractories offer excellent resistance to chemical attack. The ladles used in steelmaking are in contact with various corrosive substances, such as molten metals, slag, and fluxes. The chemical resistance of monolithic refractories prevents them from reacting with these substances, ensuring the integrity and longevity of the ladle lining. This resistance to chemical attack reduces the frequency of repairs and replacements, minimizing downtime and improving the overall efficiency of ladle operations. Furthermore, the installation of monolithic refractories is relatively quick and straightforward compared to traditional brick linings. This ease of installation saves time and labor costs, allowing for faster turnaround between ladle operations. It enables steel manufacturers to optimize their production schedules and enhance overall operational efficiency. In conclusion, monolithic refractories contribute significantly to the overall efficiency of steel ladle operations. Their excellent thermal insulation properties, high refractoriness, resistance to chemical attack, and ease of installation all play vital roles in improving energy efficiency, reducing downtime, and enhancing productivity. By choosing monolithic refractories, steel manufacturers can achieve optimized ladle performance and ultimately improve their overall steelmaking process.

- Q: Can monolithic refractories be used for the lining of ladle refining furnaces and VOD converters?

- Yes, monolithic refractories can be used for the lining of ladle refining furnaces and VOD converters. Monolithic refractories are versatile and can be shaped and installed easily, making them suitable for lining various types of furnaces and converters, including ladle refining furnaces and VOD converters.

- Q: What are the main factors affecting the thermal conductivity of monolithic refractories?

- The main factors affecting the thermal conductivity of monolithic refractories are the composition and structure of the refractory material, the porosity and density of the material, the presence of any impurities or defects, and the temperature and pressure conditions at which the refractory is being used.

- Q: How do monolithic refractories help in enhancing the durability of iron and steel equipment?

- Monolithic refractories help enhance the durability of iron and steel equipment by providing a protective lining that withstands high temperatures, chemical corrosion, and mechanical stress. This lining acts as a barrier, preventing the contact between the equipment and harsh operating conditions, thus minimizing wear and extending the lifespan of the equipment.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish drying systems?

- Monolithic refractories play a crucial role in improving the efficiency of ladle and tundish drying systems. These systems are used in the steel industry for the drying process of ladles and tundishes before they are used for casting molten steel. One of the main advantages of monolithic refractories is their ability to provide a seamless lining, without any joints or gaps. This ensures that there are no weak points in the lining, reducing the risk of heat loss during the drying process. By maintaining a uniform and continuous lining, monolithic refractories help to achieve faster and more efficient drying of ladles and tundishes. Furthermore, monolithic refractories have excellent thermal insulation properties. They have low thermal conductivity, which means that they can effectively retain heat and prevent its transfer to the surroundings. This insulation capability allows for better heat retention within the ladles and tundishes during the drying process, resulting in faster and more energy-efficient drying. Monolithic refractories also offer superior thermal shock resistance. During the drying process, ladles and tundishes are subjected to rapid temperature changes, which can cause thermal stress and lead to cracks or spalling of the lining. However, monolithic refractories have high resistance to thermal shock, ensuring the durability and longevity of the lining. This resistance to thermal shock minimizes the need for frequent repairs or replacements, thereby increasing the overall efficiency of the ladle and tundish drying systems. In addition, monolithic refractories have good corrosion resistance. They are designed to withstand the harsh conditions and corrosive environments that ladles and tundishes are exposed to during the drying process. This corrosion resistance helps to maintain the integrity of the lining, preventing any degradation or damage that could affect the efficiency of the drying systems. Overall, the use of monolithic refractories in ladle and tundish drying systems improves their efficiency by providing a seamless lining, excellent thermal insulation, thermal shock resistance, and corrosion resistance. These properties contribute to faster drying times, energy savings, reduced maintenance requirements, and increased longevity of the equipment.

Send your message to us

Monolithic Refractories High Performance & Temperature Ladle Slide Gate for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords