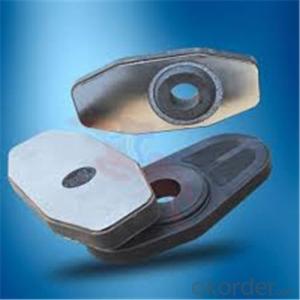

Monolithic Refractories High Temperature Ladle Sliding Gate for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

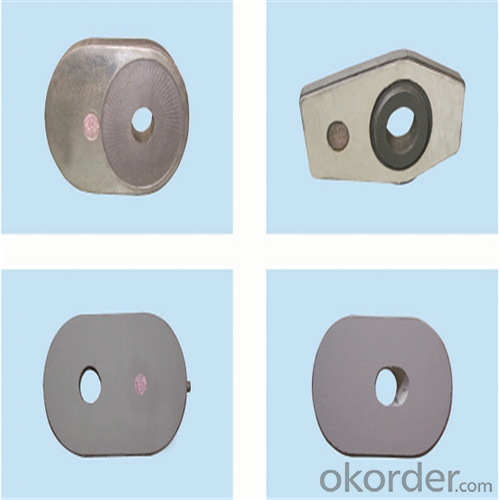

Quick Details for High Performance Refractory Ladle Slide Gate

| Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Alumina Block |

| SiO2 Content (%): | N/A | Al2O3 Content (%): | 80-90% | MgO Content (%): | N/A |

| CaO Content (%): | N/A | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | N/A |

| SiC Content (%): | N/A | Model Number: | CS80 | Brand Name: | |

| Product name: | High performance refractory ladle slide gate | Model No.: | cs80 | Brand name: | CMAX |

| Quality: | Al-C or Al-Zr-C | Service life: | 4-6 heats | Apparent porosity: | 7% Max |

| Bulk density:: | 3.1 MIN | C.C.S: | 120MPA | MOQ: | 100 pcs for trial |

| Delivery time: | 60 working days upon receipt of deposit |

Packaging & Delivery

| Packaging Details: | Inner carton packing, outer wooden case suitable for long term sea shipping |

| Delivery Detail: | three months working days upon receipt of deposit |

Specifications

Surface flatness less than 0.05mm

High mechanical strength

Erosion resistance

Oxidation resistance

Thermal shock stability

General Chemical Analysis for refractory ladle slide gate :

slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Alumina -Zirconia-Carbon material

| Al-Zr-C Material | |||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 85 | 3 | 5 | 7 | 3.1 | 120 |

| 85 | 3 | 4 | 7 | 3.1 | 120 |

Composite type: Al-Zr-C for working line, outer Al-C material

| Al-Zr-C & Al-C Material | ||||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S | |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) | |

| Inner side (Working face) | 85 | 3 | 4 | 7 | 3.1 | 120 |

| Outside | 90 | 3 | 0 | 9 | 3 | |

Using the raw materials of tabular alumina, zirconia-corundum, carbon and other high-grade additives, after sintering to obtain characteristics of oxidation resistance, scour strength, erosion resistance, thermal shock resistance, shape stable and long service life, made our products the preferred materials for the large and medium-sized steel ladle, refining ladle, series of alloy steel ladle, and tundish. Our high performance sintering sliding gates include alumina carbon , Al2O3-ZrO2-C, etc, can meet the needs of different steel grade.

Other Products

About us

Welcome to visit our factory~

- Q: How do monolithic refractories contribute to energy efficiency in iron and steel production?

- Enhancing energy efficiency in iron and steel production processes is a crucial role played by monolithic refractories. These refractories, which are unshaped materials, are utilized to line the components of furnaces, kilns, and other high-temperature equipment involved in the production of iron and steel. One method by which monolithic refractories contribute to energy efficiency is through their excellent insulation properties. These materials possess low thermal conductivity, effectively reducing heat transfer from the furnace or kiln to the surrounding environment. By minimizing heat loss, monolithic refractories aid in maintaining high temperatures within the production units, ultimately reducing the energy required to sustain the desired operating conditions. Moreover, monolithic refractories offer exceptional resistance to thermal shock and wear, ensuring the longevity of the lining materials. This durability diminishes the need for frequent repairs and replacements, resulting in less downtime and increased operational efficiency. Consequently, energy is conserved as the production units can continuously operate at optimal temperatures without interruptions. Additionally, monolithic refractories exhibit excellent resistance to chemical reactions, corrosion, and erosion caused by molten metals and slag. This resistance decreases the formation of cracks and defects in the lining, which can compromise the insulation and increase heat loss. By maintaining a robust and intact lining, monolithic refractories contribute to energy efficiency by minimizing heat escape and ensuring the efficient utilization of energy for the iron and steel production processes. Furthermore, the utilization of monolithic refractories allows for design flexibility in the construction of furnaces and kilns. Their ability to be shaped and applied in various configurations enables the creation of optimized lining structures that enhance heat transfer and combustion efficiency. This flexibility empowers engineers and operators to design and modify the production units to maximize energy efficiency and minimize energy wastage. In conclusion, monolithic refractories significantly contribute to energy efficiency in iron and steel production through their excellent insulation, durability, resistance to thermal and chemical degradation, and design flexibility. By reducing heat loss, minimizing repairs and replacements, and optimizing heat transfer, these refractories play a vital role in conserving energy and improving the overall sustainability of the iron and steel industry.

- Q: What are the key trends in the use of monolithic refractories in the iron and steel industry?

- There are several key trends in the use of monolithic refractories in the iron and steel industry that are worth noting. Firstly, there is a growing demand for monolithic refractories due to their superior performance characteristics compared to traditional brick refractories. Monolithic refractories offer higher thermal shock resistance, better insulation properties, and improved resistance to chemical attacks. This has led to their increased usage in various applications within the iron and steel industry. Secondly, there is a shift towards the use of low-cement and ultra-low cement castables in monolithic refractories. These materials have a reduced cement content, resulting in improved refractory properties such as higher strength, better corrosion resistance, and increased resistance to thermal spalling. This trend is driven by the need to enhance the overall efficiency and durability of refractory linings in iron and steel manufacturing processes. Another important trend is the development of advanced monolithic refractories with enhanced sustainability and environmental performance. The iron and steel industry is under increasing pressure to reduce its carbon footprint and minimize environmental impact. As a result, there is a growing emphasis on the use of environmentally friendly binders and additives in monolithic refractories. These new materials not only offer excellent refractory properties but also contribute to the industry's sustainability goals. Furthermore, there is a rising focus on the development of monolithic refractories that can withstand extreme operating conditions. Iron and steel manufacturing processes involve high temperatures, aggressive chemical environments, and severe mechanical stresses. Therefore, there is a need for monolithic refractories that can endure these harsh conditions without compromising their performance. The industry is investing in research and development to create refractories that provide exceptional resistance to thermal shock, abrasion, and erosion. Lastly, there is an increasing adoption of digital and smart technologies in the monitoring and maintenance of monolithic refractories. With the advancements in sensor technology and data analytics, it is now possible to collect real-time data on the condition and performance of refractory linings. This allows for proactive maintenance, early detection of potential issues, and optimization of refractory usage, resulting in improved operational efficiency and cost savings. In conclusion, the key trends in the use of monolithic refractories in the iron and steel industry include the demand for superior performance, the shift towards low-cement and ultra-low cement castables, the development of sustainable materials, the focus on extreme operating conditions, and the adoption of digital and smart technologies for monitoring and maintenance. These trends reflect the industry's continuous efforts to enhance the efficiency, durability, and environmental sustainability of refractory linings in iron and steel manufacturing processes.

- Q: How do monolithic refractories withstand the chemical attacks in aluminum furnace applications?

- Monolithic refractories are able to withstand chemical attacks in aluminum furnace applications due to their unique composition and properties. These materials are designed to have high resistance to the corrosive effects of molten aluminum and other chemicals present in the furnace environment. Firstly, monolithic refractories are made from a combination of different minerals, such as alumina, silicon carbide, and zirconia, which have high melting points and excellent chemical stability. These minerals act as a barrier between the corrosive substances and the underlying structure, preventing them from penetrating or damaging the refractory lining. Additionally, monolithic refractories are typically formulated with high levels of alumina, which provides them with exceptional resistance to chemical attacks. Alumina has a strong affinity for oxygen, forming a stable oxide layer on the surface of the refractory material, acting as a protective barrier against corrosive elements. This oxide layer also helps to reduce the rate of penetration of corrosive substances into the refractory lining. Moreover, monolithic refractories are often designed with a dense microstructure and low porosity. This ensures that there are fewer pathways for the corrosive substances to penetrate and attack the refractory material. The denser the material, the less susceptible it is to chemical attacks. Furthermore, monolithic refractories can be further enhanced by adding additives or binders that improve their resistance to chemical attacks. These additives can include various organic or inorganic materials that provide additional protection against corrosive substances. Overall, monolithic refractories are specifically engineered to withstand the harsh conditions of aluminum furnace applications. Their unique composition, high alumina content, dense microstructure, and resistance-enhancing additives all contribute to their ability to withstand chemical attacks and prolong the lifespan of the refractory lining in aluminum furnaces.

- Q: How do monolithic refractories prevent heat loss through convection?

- Monolithic refractories prevent heat loss through convection by their unique composition and structure. Unlike traditional refractory bricks, which are often porous and have gaps between them, monolithic refractories are made of a single, seamless structure. This eliminates any potential pathways for hot gases or air to circulate and carry away the heat through convection. Additionally, monolithic refractories are often dense and have a high thermal conductivity, which means they are excellent conductors of heat. This property allows them to quickly absorb and distribute the heat, minimizing the temperature difference between the hot surface and the surrounding environment. By reducing the temperature gradient, monolithic refractories minimize the driving force for convection, thereby reducing heat loss through this mechanism. Furthermore, monolithic refractories can be applied as a continuous lining, conforming to the shape of the equipment or furnace being protected. This seamless application eliminates joints or gaps where hot gases or air could escape and carry away heat. This uniform, uninterrupted lining further reduces the potential for convection heat loss. Overall, monolithic refractories are designed to create a barrier that prevents the movement of hot gases or air, thereby minimizing heat loss through convection. Their dense composition, high thermal conductivity, and seamless application all contribute to their effectiveness in preventing heat loss through this mechanism.

- Q: How do monolithic refractories enhance the performance of ladles and tundishes?

- Monolithic refractories enhance the performance of ladles and tundishes by providing superior thermal insulation, high resistance to thermal shock, and excellent chemical resistance. This improves their durability, reduces heat loss, and minimizes the risk of refractory failure, resulting in increased operational efficiency and extended service life of ladles and tundishes.

- Q: Can monolithic refractories be used in electric arc furnaces and induction furnaces?

- Yes, monolithic refractories can be used in both electric arc furnaces and induction furnaces. Monolithic refractories are versatile and can be shaped and installed easily, making them suitable for various types of furnaces, including electric arc furnaces and induction furnaces. These refractories are composed of a single material, such as castables, gunning mixes, ramming mixes, and plastic refractories, which can withstand high temperatures and thermal shock. They are commonly used to line the walls, roofs, and bottoms of furnaces to provide insulation and protection against the extreme heat generated during the melting and refining processes. Monolithic refractories offer excellent resistance to chemical attack, erosion, and mechanical stress, making them ideal for use in electric arc furnaces and induction furnaces, where intense heat and harsh operating conditions are encountered.

- Q: How do monolithic refractories improve the performance and efficiency of iron and steel production?

- Monolithic refractories play a crucial role in improving the performance and efficiency of iron and steel production. These specialized materials are designed to withstand extreme temperatures, chemical reactions, and mechanical stresses, making them ideal for use in high-temperature industrial processes. One of the key ways in which monolithic refractories enhance performance is by providing a protective lining in furnaces, kilns, and other equipment used in iron and steel production. Due to their superior heat resistance, they protect the underlying structure from the intense heat and prevent any detrimental effects on the equipment. This results in reduced downtime, longer service life, and ultimately, increased overall efficiency. Monolithic refractories also ensure better thermal efficiency in the production process. By minimizing heat losses, these materials help to maintain a stable and uniform temperature distribution, thereby improving the energy efficiency of the system. This is particularly important in iron and steel production, where precise temperature control is crucial for achieving the desired metallurgical properties of the final product. Furthermore, monolithic refractories offer excellent resistance to chemical corrosion, erosion, and slag attacks. They act as a barrier between the molten metal and the refractory lining, preventing undesirable reactions and material degradation. This helps to maintain the integrity of the furnace lining, reducing the need for frequent repairs or replacements. Consequently, it leads to increased productivity and cost savings in the long run. Another advantage of monolithic refractories is their ability to be easily shaped, repaired, or replaced. Unlike traditional brick refractories, which require extensive labor and time-consuming installation, monolithic refractories can be applied in a more flexible and efficient manner. Their flexible nature allows for easy repair of damaged areas, minimizing downtime and ensuring continuous production. In summary, the use of monolithic refractories significantly enhances the performance and efficiency of iron and steel production. These materials provide a protective lining, improve thermal efficiency, resist chemical corrosion, and offer easy installation and repair options. By optimizing the production process, monolithic refractories contribute to higher productivity, reduced downtime, and increased cost-effectiveness in the iron and steel industry.

- Q: What are the key innovations in monolithic refractories for the iron and steel industry?

- The iron and steel industry heavily relies on monolithic refractories, which serve as lining materials in various high-temperature processes like blast furnaces, ladles, and converters. Over time, the field of monolithic refractories has witnessed several crucial innovations that address specific challenges and enhance the overall performance of these linings. Among the significant innovations in monolithic refractories is the emergence of low cement and ultra-low cement castables. These castables contain reduced cement quantities, resulting in improved properties such as higher hot strength, better thermal shock resistance, and enhanced resistance to chemical attack. By decreasing the cement content, the refractory achieves higher density, reduced porosity, and increased mechanical strength, ultimately leading to improved durability and extended service life. Another innovation in monolithic refractories is the introduction of self-flowing castables. These castables are designed to exhibit excellent flowability and can be conveniently installed through pouring or pumping, eliminating the need for manual vibration. Self-flowing castables offer advantages like reduced installation time, improved lining quality, and enhanced performance in complex geometries or hard-to-reach areas. In recent years, advances in nanotechnology have also influenced the development of monolithic refractories. Refractory compositions now incorporate nanoparticles, such as nano-sized additives and binders, to enhance their properties. These nanoparticles enhance the refractory's mechanical strength, thermal conductivity, and corrosion resistance. Additionally, nanotechnology enables better control over refractories' microstructure, resulting in optimized performance and increased lifespan. The development of high-performance monolithic refractories has also been driven by the need for improved energy efficiency and reduced environmental impact. Insulating castables, for instance, have been created to provide excellent thermal insulation properties, leading to reduced heat loss and energy consumption in various applications. These refractories contribute to increased energy efficiency, lowered production costs, and minimized greenhouse gas emissions. Moreover, advanced installation techniques like gunning and shotcreting have revolutionized the application of monolithic refractories. These techniques enable faster and more precise installation, reducing downtime and improving productivity. Additionally, robotic application systems have been introduced, allowing for automated and consistent refractory installation, ensuring high-quality linings with minimal human intervention. In conclusion, key innovations in monolithic refractories for the iron and steel industry encompass the development of low cement and ultra-low cement castables, self-flowing castables, the incorporation of nanotechnology, the introduction of high-performance insulation materials, and advancements in installation techniques. These innovations have significantly enhanced the performance, durability, energy efficiency, and installation processes of monolithic refractories, thereby contributing to the overall efficiency and competitiveness of the iron and steel industry.

- Q: What are the main factors affecting the abrasion resistance of monolithic refractories?

- The main factors affecting the abrasion resistance of monolithic refractories are the composition of the refractory material, the size and shape of the abrasive particles, the velocity and angle of impact of the abrasives, and the temperature and pressure conditions in the application environment.

- Q: What are the recommended installation techniques for monolithic refractories?

- The recommended installation techniques for monolithic refractories depend on the specific type and application of the refractory material. However, there are some general guidelines that can be followed for most monolithic refractory installations. 1. Surface Preparation: Before installing monolithic refractories, it is crucial to ensure that the surface is clean, dry, and free from any loose particles or contaminants. This can be achieved by removing any existing refractory materials, cleaning the surface thoroughly, and allowing it to dry completely. 2. Mixing: Monolithic refractories are typically supplied in a dry or wet form, depending on the specific material. If the refractory is supplied in a dry form, it needs to be mixed with water or a suitable liquid binder to form a workable consistency. It is important to follow the manufacturer's guidelines for the correct mixing ratio and mixing time to ensure proper bonding and setting of the refractory material. 3. Application: The application technique for monolithic refractories can vary depending on the specific material and the desired installation method. Some common techniques include troweling, gunning, ramming, and casting. - Troweling: This technique involves manually applying the refractory material using a trowel. It is typically used for thin linings or patching small areas. - Gunning: Gunning is a method of applying refractory material using a gunning machine or a hand-held gun. It is suitable for large areas or areas that are difficult to access. The refractory material is mixed with water or a liquid binder and sprayed onto the surface at a high velocity. - Ramming: Ramming involves compacting the refractory material into place using a ramming tool or a pneumatic hammer. It is commonly used for forming furnace linings or repairing damaged areas. - Casting: Casting refers to pouring the refractory material into a mold to form a desired shape or lining. It is often used for creating complex shapes or large-sized components. 4. Curing and Drying: After the refractory material is applied, it needs to be properly cured and dried to achieve its maximum strength and thermal properties. The curing and drying process can vary depending on the specific material, but typically involves controlled heating at a gradual rate to remove any remaining moisture and to allow the refractory to set and harden properly. It is important to note that these are general guidelines, and it is always recommended to consult the manufacturer's instructions and specifications for the specific monolithic refractory material being used. Following the recommended installation techniques will help ensure the proper performance and longevity of the refractory lining.

Send your message to us

Monolithic Refractories High Temperature Ladle Sliding Gate for Iron and Steel Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords