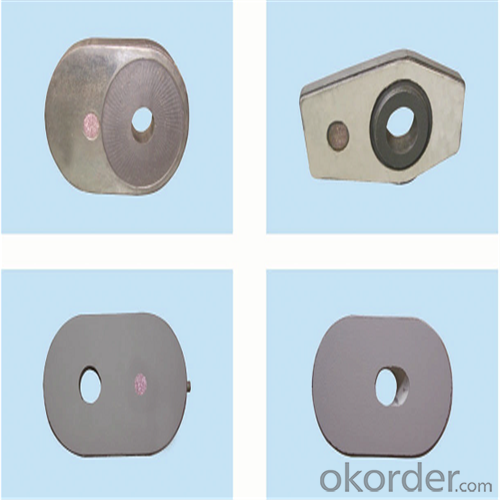

Monolithic Refractories High Performance & Temperature Ladle Sliding Gate for Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for High Performance Refractory Ladle Slide Gate

| Place of Origin: | China (Mainland) | Shape: | Plate | Material: | Alumina Block |

| SiO2 Content (%): | N/A | Al2O3 Content (%): | 80-90% | MgO Content (%): | N/A |

| CaO Content (%): | N/A | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | N/A |

| SiC Content (%): | N/A | Model Number: | CS80 | Brand Name: | |

| Product name: | High performance refractory ladle slide gate | Model No.: | cs80 | Brand name: | CMAX |

| Quality: | Al-C or Al-Zr-C | Service life: | 4-6 heats | Apparent porosity: | 7% Max |

| Bulk density:: | 3.1 MIN | C.C.S: | 120MPA | MOQ: | 100 pcs for trial |

| Delivery time: | 60 working days upon receipt of deposit |

Packaging & Delivery

| Packaging Details: | Inner carton packing, outer wooden case suitable for long term sea shipping |

| Delivery Detail: | three months working days upon receipt of deposit |

Specifications

Surface flatness less than 0.05mm

High mechanical strength

Erosion resistance

Oxidation resistance

Thermal shock stability

Using the raw materials of tabular alumina, zirconia-corundum, carbon and other high-grade additives, after sintering to obtain characteristics of oxidation resistance, scour strength, erosion resistance, thermal shock resistance, shape stable and long service life, made our products the preferred materials for the large and medium-sized steel ladle, refining ladle, series of alloy steel ladle, and tundish. Our high performance sintering sliding gates include alumina carbon , Al2O3-ZrO2-C, etc, can meet the needs of different steel grade.

General Chemical Analysis for refractory ladle slide gate :

slide gate plate widely including Alumina carbon and Alumina Zirconia Carbon slide gate plate, MgO and MgO-spinel slide gate plate,nonoxides bonding slide gate plateand unburned slide gate plate.

Alumina -Zirconia-Carbon material

| Al-Zr-C Material | |||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) |

| 85 | 3 | 5 | 7 | 3.1 | 120 |

| 85 | 3 | 4 | 7 | 3.1 | 120 |

Composite type: Al-Zr-C for working line, outer Al-C material

| Al-Zr-C & Al-C Material | ||||||

| Al2O3 | C | ZrO2 | Apparent porosity | Bulk density | C.C.S | |

| (% minm) | (% minm) | (% minm) | (% max) | (gm./cc minm) | (MPa minm) | |

| Inner side (Working face) | 85 | 3 | 4 | 7 | 3.1 | 120 |

| Outside | 90 | 3 | 0 | 9 | 3 | |

Other Products

About us

Sample is on your request.

Welcome to visit our factory~

- Q: How do monolithic refractories perform in rotary hearth furnace applications?

- Monolithic refractories perform exceptionally well in rotary hearth furnace applications due to their ability to withstand high temperatures, thermal shock, and mechanical stresses. Their unique properties and composition make them highly resistant to chemical attacks and erosion, ensuring long-lasting and reliable performance in these demanding environments. Additionally, their easy installation and repair process make them a preferred choice for rotary hearth furnace applications.

- Q: How do monolithic refractories contribute to the overall efficiency of ladles and tundishes?

- There are several ways in which monolithic refractories greatly improve the effectiveness of ladles and tundishes. Initially, the exceptional thermal insulation properties of monolithic refractories are well-known. By lining the ladles and tundishes with these refractories, heat loss is minimized, resulting in reduced energy consumption and improved thermal efficiency. This insulation capability also helps in maintaining a consistent temperature within the ladles and tundishes, which is vital for the proper casting and solidification of molten metal. Furthermore, monolithic refractories provide excellent resistance to thermal shocks and chemical corrosion. Ladles and tundishes are exposed to extreme temperatures and harsh chemical environments due to their contact with molten metal and various fluxes or additives. The use of monolithic refractories ensures that the ladles and tundishes have a longer lifespan by preventing cracking, spalling, or erosion caused by these harsh conditions. As a result, there is less downtime for maintenance and replacement, leading to increased overall efficiency. Moreover, the flexibility and ease of installation of monolithic refractories contribute to the efficiency of ladles and tundishes. Unlike traditional brick lining, monolithic refractories can be easily shaped and installed in different sizes and forms. This versatility allows for better customization and optimization of ladles and tundishes. This adaptability helps to improve the flow dynamics of molten metal, reducing turbulence, and enhancing the overall casting process efficiency. In conclusion, monolithic refractories significantly enhance the efficiency of ladles and tundishes through their exceptional thermal insulation properties, resistance to thermal shocks and chemical corrosion, and flexibility in installation. By reducing heat loss, extending the lifespan, and optimizing the casting process, monolithic refractories make a significant contribution to the overall efficiency and productivity of ladles and tundishes in the metal industry.

- Q: What are the key characteristics of monolithic refractories for electric arc furnace applications?

- Monolithic refractories designed for electric arc furnace applications possess several crucial qualities that render them suitable for the challenging conditions and extreme temperatures encountered in these environments. To begin with, monolithic refractories exhibit exceptional resistance to thermal shock. Electric arc furnaces operate at exceedingly high temperatures, and the rapid fluctuations in temperature during the melting and refining processes can subject the refractories to significant thermal stress. Monolithic refractories, however, are engineered to endure these thermal shocks without developing cracks or spalling, thereby guaranteeing the durability and performance of the lining. Moreover, monolithic refractories boast a high resistance to chemical attack. Electric arc furnaces involve the melting and refining of diverse metals and alloys, which can generate highly corrosive atmospheres. Monolithic refractories incorporate chemically inert materials and additives that bestow resistance against the corrosive impact of molten metals and slag, safeguarding the lining against chemical deterioration. Another noteworthy characteristic of monolithic refractories for electric arc furnace applications is their exceptional refractoriness. Refractoriness denotes a material's ability to retain its strength and integrity at elevated temperatures. Electric arc furnaces typically operate at temperatures surpassing 1500°C, and monolithic refractories are specifically engineered to endure these extreme conditions without experiencing substantial loss of properties or degradation. Furthermore, monolithic refractories offer efficient thermal conductivity. This property facilitates efficient heat transfer throughout the lining, ensuring uniform heating and melting of the charge material. It also helps minimize the occurrence of hot spots and thermal gradients, which can result in uneven wear and premature failure of the lining. Lastly, monolithic refractories are renowned for their ease of installation and repair. Unlike traditional brick or block refractories, monolithic materials can be cast, sprayed, or rammed into place, eliminating the need for intricate masonry work. This not only saves time and labor but also enables convenient maintenance and repair of the lining, reducing downtime and enhancing overall furnace efficiency. In conclusion, monolithic refractories for electric arc furnace applications possess exceptional thermal shock resistance, high chemical resistance, high refractoriness, efficient thermal conductivity, and ease of installation and repair. These qualities render monolithic refractories ideal for withstanding the harsh conditions and demanding requirements of electric arc furnace operations.

- Q: Can monolithic refractories be used for the lining of continuous casting tundishes and molds?

- Yes, monolithic refractories can be used for the lining of continuous casting tundishes and molds. Monolithic refractories are a type of refractory material that is composed of a single, homogeneous structure, in contrast to traditional refractories that are made up of multiple bricks or tiles. Monolithic refractories offer several advantages for lining tundishes and molds in continuous casting processes. Firstly, their monolithic nature allows for easy installation and repair, as they can be cast or gunned into place, eliminating the need for complex brickwork. This results in reduced downtime and increased productivity. Additionally, monolithic refractories have excellent thermal shock resistance, which is crucial for tundishes and molds that experience rapid and extreme temperature changes during the casting process. Their high thermal conductivity also ensures efficient heat transfer, promoting uniform cooling and solidification of the cast metal. Moreover, monolithic refractories offer good resistance to chemical attack, ensuring long-lasting performance even in the presence of molten metal and slag. They also have low porosity, preventing the penetration of metal and preventing the formation of cracks and spalling. Overall, monolithic refractories are a viable and effective choice for lining continuous casting tundishes and molds, providing superior performance, ease of installation, and durability in the demanding conditions of the casting process.

- Q: How do monolithic refractories withstand the mechanical impacts in furnace door applications?

- Monolithic refractories withstand mechanical impacts in furnace door applications due to their high strength and resistance to thermal shock. These refractories are composed of dense and uniform materials, such as castables or plastics, which provide excellent structural integrity and the ability to withstand heavy loads and vibrations. Additionally, they have low porosity and high thermal conductivity, allowing them to dissipate heat efficiently and reduce the risk of cracking or spalling under mechanical stress.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish purging furnaces?

- Monolithic refractories play a crucial role in improving the efficiency of ladle and tundish purging furnaces in several ways. Firstly, monolithic refractories have excellent thermal insulation properties. This means that they can retain heat within the furnace, minimizing heat loss to the surroundings. By reducing heat loss, monolithic refractories enable the furnaces to operate at higher temperatures, which in turn leads to improved efficiency. The higher temperatures allow for better steel refining, faster heating and purging of the ladle and tundish, and overall increased productivity. Secondly, monolithic refractories offer superior resistance to thermal shock. Purging furnaces, especially ladles and tundishes, undergo rapid heating and cooling cycles due to the continuous flow of molten metal. This thermal cycling can cause traditional refractories to crack or fail, leading to reduced efficiency and increased downtime for repairs. However, monolithic refractories have the ability to withstand these extreme temperature changes, ensuring continuous operation and minimizing the need for frequent maintenance. Thirdly, monolithic refractories provide excellent resistance to chemical attacks from molten metals and slag. During the purging process, ladles and tundishes come into contact with aggressive materials that can erode the refractory lining. Monolithic refractories are specifically engineered to withstand these harsh environments, preventing erosion and prolonging the lifespan of the furnaces. This resistance to chemical attacks not only improves efficiency by minimizing refractory wear, but also ensures the production of high-quality steel with reduced impurities. Lastly, monolithic refractories offer great versatility in terms of installation and repair. Unlike traditional refractories that require complex bricklaying techniques, monolithic refractories can be easily shaped and installed, allowing for faster and more efficient lining construction. Additionally, monolithic refractories can be easily repaired or patched, reducing downtime and ensuring continuous operation of the furnace. In conclusion, monolithic refractories greatly improve the efficiency of ladle and tundish purging furnaces by providing excellent thermal insulation, resistance to thermal shock and chemical attacks, as well as ease of installation and repair. These properties allow for higher operating temperatures, reduced heat loss, increased productivity, and prolonged furnace lifespan, ultimately enhancing the overall efficiency and performance of the steelmaking process.

- Q: What are monolithic refractories?

- Monolithic refractories, in contrast to individual bricks or precast shapes, are refractory materials that are manufactured as a single unit. They can be shaped and installed without the need for joints or mortar, making them convenient for lining furnaces, boilers, kilns, and other high-temperature industrial equipment. These refractories consist of a carefully selected mixture of refractory aggregates, binders, and additives. This combination provides desired properties such as high temperature resistance, thermal shock resistance, and chemical durability. Aggregates like alumina, magnesia, zirconia, and silica are used, while binders such as clay, cement, or phosphate hold the aggregates together. One advantage of monolithic refractories is their ability to adapt to complex shapes and designs, allowing for customized linings that meet specific equipment requirements. They can be applied through pouring, gunning, ramming, or spraying onto the surface to be lined, leading to quick and efficient installation. This eliminates the need for time-consuming bricklaying and jointing, reducing installation time and labor costs. Monolithic refractories also possess superior thermal conductivity, enabling them to withstand high temperatures and sudden temperature changes. They offer excellent insulation properties, preventing heat loss and improving energy efficiency in industrial processes. Additionally, these refractories exhibit good resistance to chemical attack from molten metals, slags, gases, and other corrosive substances found in various industrial environments. This makes them highly suitable for applications in steel, cement, glass, petrochemical, and non-ferrous metals industries. In conclusion, monolithic refractories are a versatile and efficient solution for high-temperature applications. Their ability to be shaped and installed without joints or mortar, combined with their excellent thermal conductivity and chemical resistance, make them a valuable choice for lining industrial equipment operating under extreme conditions.

- Q: What are the recommended installation techniques for monolithic refractories?

- The recommended installation techniques for monolithic refractories depend on the specific type and application of the refractory material. However, there are some general guidelines that can be followed for most monolithic refractory installations. 1. Surface Preparation: Before installing monolithic refractories, it is crucial to ensure that the surface is clean, dry, and free from any loose particles or contaminants. This can be achieved by removing any existing refractory materials, cleaning the surface thoroughly, and allowing it to dry completely. 2. Mixing: Monolithic refractories are typically supplied in a dry or wet form, depending on the specific material. If the refractory is supplied in a dry form, it needs to be mixed with water or a suitable liquid binder to form a workable consistency. It is important to follow the manufacturer's guidelines for the correct mixing ratio and mixing time to ensure proper bonding and setting of the refractory material. 3. Application: The application technique for monolithic refractories can vary depending on the specific material and the desired installation method. Some common techniques include troweling, gunning, ramming, and casting. - Troweling: This technique involves manually applying the refractory material using a trowel. It is typically used for thin linings or patching small areas. - Gunning: Gunning is a method of applying refractory material using a gunning machine or a hand-held gun. It is suitable for large areas or areas that are difficult to access. The refractory material is mixed with water or a liquid binder and sprayed onto the surface at a high velocity. - Ramming: Ramming involves compacting the refractory material into place using a ramming tool or a pneumatic hammer. It is commonly used for forming furnace linings or repairing damaged areas. - Casting: Casting refers to pouring the refractory material into a mold to form a desired shape or lining. It is often used for creating complex shapes or large-sized components. 4. Curing and Drying: After the refractory material is applied, it needs to be properly cured and dried to achieve its maximum strength and thermal properties. The curing and drying process can vary depending on the specific material, but typically involves controlled heating at a gradual rate to remove any remaining moisture and to allow the refractory to set and harden properly. It is important to note that these are general guidelines, and it is always recommended to consult the manufacturer's instructions and specifications for the specific monolithic refractory material being used. Following the recommended installation techniques will help ensure the proper performance and longevity of the refractory lining.

- Q: How do monolithic refractories improve the efficiency of ladle and tundish drying furnaces?

- The efficiency of ladle and tundish drying furnaces is enhanced by monolithic refractories in multiple ways. To begin with, monolithic refractories provide a high level of thermal insulation. These refractories possess low thermal conductivity, effectively minimizing heat transfer from the furnace to the surrounding environment. This insulation property helps to reduce heat losses and maintain a higher temperature within the furnace for a longer duration. Consequently, the drying process becomes more efficient as the heat is retained within the furnace, resulting in a decrease in overall energy consumption. Furthermore, monolithic refractories exhibit exceptional resistance to thermal shock. The rapid temperature fluctuations that occur during the heating and cooling cycles of the furnace can cause stress and cracks in the refractory material. However, monolithic refractories are designed to withstand these thermal shocks and maintain their structural integrity. This durability ensures a longer lifespan for the refractory lining, reducing the need for frequent repairs or replacements. Consequently, the furnace operates at optimal efficiency without the downtime associated with maintenance. In addition, monolithic refractories offer excellent mechanical strength and abrasion resistance. These properties are crucial in ladle and tundish drying furnaces, which are subjected to mechanical stresses and abrasive substances like molten metal and slag. The use of monolithic refractories ensures that the lining can endure these harsh conditions without suffering structural damage. This resistance to wear and tear increases the overall efficiency of the furnace, enabling it to operate uninterrupted for longer periods. Lastly, monolithic refractories provide greater design flexibility compared to traditional brick or tile refractories. They can be easily cast or gunned onto the lining surface, simplifying installation and repair processes. This flexibility allows the furnace to be customized and adapted to meet specific requirements, ensuring optimal heat distribution and efficient drying processes. In conclusion, monolithic refractories enhance the efficiency of ladle and tundish drying furnaces through their thermal insulation, resistance to thermal shock, mechanical strength, and design flexibility. By reducing heat losses, increasing durability, withstanding harsh conditions, and facilitating easy installation and repair, these refractories optimize the performance and energy efficiency of the furnaces.

- Q: What are the typical properties of monolithic refractories used in iron and steel industry?

- Monolithic refractories used in the iron and steel industry generally possess several key properties that make them suitable for the harsh operating conditions in these industries. Firstly, monolithic refractories have excellent thermal shock resistance. They can withstand rapid temperature changes without cracking or spalling, which is crucial in the iron and steel industry where the heating and cooling processes can be highly intense. Secondly, these refractories exhibit high refractoriness, meaning they can withstand extremely high temperatures without losing their strength or shape. This is essential in environments where temperatures can reach well above 1000 degrees Celsius. Additionally, monolithic refractories used in the iron and steel industry are known for their excellent corrosion resistance. They can resist the corrosive effects of molten metals, slags, and gases that are commonly encountered in these industrial processes. Furthermore, these refractories have good mechanical strength and abrasion resistance, allowing them to withstand the physical stresses and wear caused by handling and mechanical operations. Another important property of monolithic refractories is their ability to form strong bonds with the existing refractory lining. This ensures a secure and long-lasting installation, reducing the risk of failure and minimizing downtime for maintenance or repairs. Lastly, these refractories often have low porosity, which prevents the infiltration of molten metal or slag into the lining. This helps to maintain the integrity of the refractory structure and prolong its service life. Overall, the typical properties of monolithic refractories used in the iron and steel industry include thermal shock resistance, high refractoriness, corrosion resistance, mechanical strength, strong bonding, and low porosity. These properties collectively contribute to the efficient and reliable operation of iron and steel manufacturing processes.

Send your message to us

Monolithic Refractories High Performance & Temperature Ladle Sliding Gate for Steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords