High-performace pipeline ball valve DN3 inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of pipeline ball valve

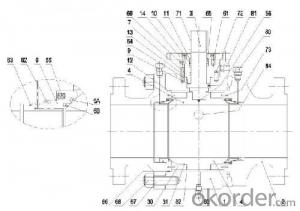

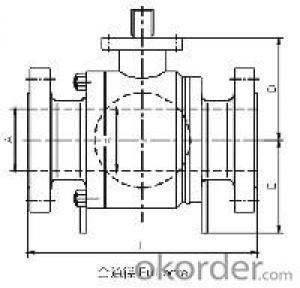

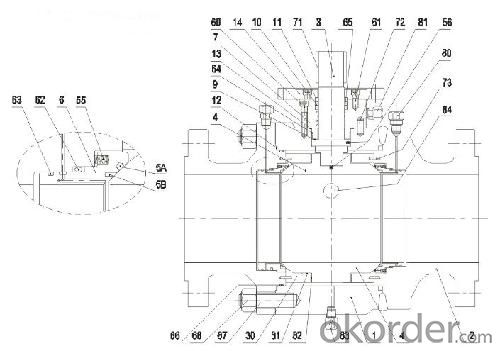

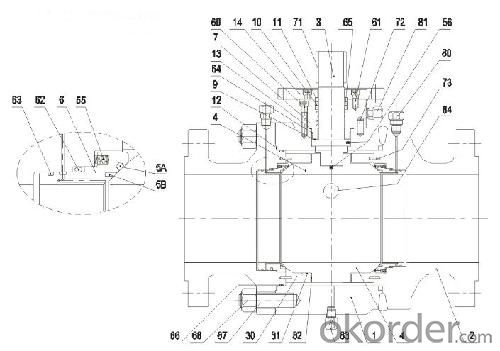

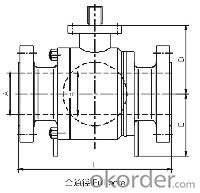

Body of high-performance pipeline ball valve is forged structure.The connection type for body and vice-body can be BB(bolted connection)and WB(welded connection).The WB(welded connection)and the LWB(Fully-welded extended stem)structure isadopted for buried ball valves,as shown below.

High performance pipeline ball valve series has the feature of strength,high perfect sealing,maintenance-free,long life and so on.The production of this series ball valve adopts the international advanced ball valve design and manufacturing technology,selects high-quality materials in accordance with the standard selection of materials and combines with advanced materials forming forging technology.At the same time,with the years of ball valve design and manufacturing experience,the use of advanced processing and manufacturing equipment and production and processing technology,through the first-class inspection and testing equipment and instruments,perfect quality assurance management system and excellence in the production of high-performance philosophy can ensure the quality of valves.This series of valve has the performance of a high strength,defect-free forging body,excellent sealing performance,even at maximum pressure difference(full pressure),it will still be able to ensure that seal without leakage,after frequent switching action to realize a safe usage in the transportation of oil,natural gas,coal gas,and other special medium transportation pipeline.

Performance & Dimensions of pipeline ball valve

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 1.6 Mpa 2 Mpa 5 Mpa 8 Mpa 10 Mpa 16 Mpa 25 Mpa 42 Mpa |

150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize | |

Valve Size | 50 mm 80 mm 100 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 550 mm 600 mm 650 mm 700 mm 750 mm 800 mm 850 mm 900 mm 1000 mm 1050 mm 1200 mm 1400 mm |

2 inch 3 inch 4 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 22 inch 24 inch 26 inch 28 inch 30 inch 32 inch 34 inch 36 inch 40 inch 42 inch 48 inch 56 inch customize | |

Actuator | Electric Handle Hydraulic Pilot-hydraulic Pneumatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

Medium | Gas customize |

Medium Temperature | -29~150℃ -46~150℃ customize |

Application Fields | Electricity Petrochemical Power Station customize |

Component Materials of pipeline ball valve

1-Body Material | A105 A350-LF2-M customize |

2-Bonnet | A105 A350-LF2-M customize |

3-Stem | 4410+ENP customize |

4-Ball | A350 LF2+ENP A105+ENP customize |

5-Material of Valve Seat | fluorine rubber customize |

5-Seat | Nylon PTFE peek DEVLON customize |

6-Seat ring | A105 ENP+A322 4140 customize |

7-Packing chamber | A322 4140+ENP A105 customize |

9-Stem gasket | RPTFE customize |

10-Packing | graphite PTFE customize |

11-Packing gland | ENP+A350 LF2 ENP+A105 customize |

12-Body gasket | Stainless steel+graphite customize |

13-Gasket | Stainless steel+graphite customize |

14-Top flange | A105 A350 LF2 customize |

30-Supporting board | A105 A350 LF2 customize |

31-Gasket | customize |

55-Seat spring | B637 Inconel X750 customize |

56-Anti-static spring | B637 Inconel X750 customize |

60-Bolt | A320 L7 A193-B7 A193-B7M customize |

61-Bolt | A193-B7 A193-B7M A320 L7 customize |

62-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

63-Fire-safe ring | flexible graphite customize |

64-O-ring | hydrogenated nitrile butadiene rubber fluorine rubber customize |

65-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

66-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

67-Bolt | A193-B7M A320 L7 A193-B7 customize |

68-Nut | A194 2HM A194 4 A194 2H customize |

71-Key | A322 4140 customize |

72-Locating pin | A322 4140 customize |

73-Locating pin | A322 4140 customize |

80-Seat injection valve | WCB+ENP customize |

81-Stem injection valve | WCB+ENP customize |

82-Bearing | PTFE+Stainless steel customize |

83-Drainage valve | Stainless steel customize |

84-Vent valve | Stainless steel customize |

85-Actuator | customize |

90-Plate | Stainless steel customize |

Standards Applied of pipeline ball valve

Design Standard | API 6D customize |

Connection Standard | ASME B 16.25-2007 ASME B 16.5 ASME B 31.4 ASME B 31.8 DIN GB、GB/T JB、JB/T JIS customize |

Test Standard | API 6D customize |

Face to Face | API 6D customize |

Pressure-temperature rating | ASME B 16.34-2004 customize |

Marking | MSS SP-25 customize |

Images of pipeline ball valve:

FAQ of pipeline ball valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: my check engine light just came on and i have some oil on the block of my engine, a friend told me that the valve cover gasket needs resealed. could that be why my check engine light is on?

- I assume you checked the oil level. You can go to Auto Zone and have engine codes checked for free to see if you have a problem. I can't see how a leaky valve cover would cause the check engine light to come on unless it fouled some sensor but then again I'm no mechanic.

- Q: What are better valve cover gaskets for a car? Cork kind? Or the rubber kind? Or either rubber/cork kind?

- For the inexperienced I would choose rubber it is harder to mess up by overtightening and if you clean the surface it will seal good

- Q: i have a puegeot 306 turbo diesel and apparently removing the EGR valve helps with engine noise and the smokeyness of the car. Is there any downside to removing it?

- The EGR Valve (Exhaust Gas Recirculation Valve) aids in warming up the engine to operating Temperature. The engine is designed for maxi mun efficiency and optimum power at a pre determined Temperature. If you are getting alot of engine noise or alot of smoke, the EGR valve isn't the problem. And removing it may improve the condition some, however, your engine has other issues. The downside on removing it from a diesel engine is by lowering the heat generated to the cylinders, you reduce the engines ability to burn all of the fuel. Diesel engine burn the fuel through compression and heat.... not spark. So lowering the cylinder Temperature leaves fuel in the cylinder that is unburnt. It will aid in lubrication to the cylinder but eventually may cause wet stack. The cylinders staying wet with unburnt fuel. Over time, if enough fuel builds up, the engine may experience a hydraulic lock.

- Q: I go deer hunting with my dad and he has an artificial heart valve. It isn't too loud, but I can hear it about ten feet away if it's quiet enough. Is it possible that we haven't shot any deer yet because the deer can hear the valve and know to stay away?

- I seriously doubt that the valve is the reason...even if the deer could hear it, they wouldn't know to connect the weird noise to a hunter...they'd be more likely to smell you.

- Q: When you regulate flow with a valve in a fluid circuit, obviously the flow changes. But mathematically, it changes in function to what? the minimum cross-sectional area? I mean it has to have something to do with some integral of sth (since a valve can change the cross-sectional area of a portion of the tube with length of almost zero and the flow would still change dramatically). I have no idea how to work this through. Can you tell me what changes when you close a valve, which makes the total flow change?Please answer asprecisely as possible, this is for a college essay! thanks in advance!

- The flow coefficient is a measurement usually given for a valve fully open, identified in the specs as the Cv. It basically tells you how much flow you'll get through the valve for a given pressure differential across it, or conversely how much your pressure will drop if you force a certain volume through it. Some valve types are effectively orifices (gate valves) or short lengths of pipe (non-full-port ball valves), others like solenoid types have more complicated internal paths the reduce flow because of the fluid having to change directions in addition to squeezing through orifices.

- Q: I just fixed a clog in my bathroom sink by taking off the p-trap. I had turned off the water valve beforehand, and when I was done I turned it back on. After this, all that came out of the faucet was a trickle. Turning the valve in the off position does not stop the trickle. When I first turned the valve off before taking off the pipe, the valve was not turned all the way left or right. It was in the middle, but the water flowed fine. When I turned the valve all the way to the right, the water shut off at the faucet. My apartment is pretty old. Is this valve most likely broken?

- Like the first person said, put it back in the original middle position. It could be a ball type valve, meaning it has a ball with a hole in it. To the far left or far right the hole to allow water to go through would be against the pipe wall, not allowing water through. In the middle, the hole would be aligned with the pipe wall and let water through. If that doesn't work, it is likely broken, especially if the valve was wanting to stick hard beforehand or you felt a quick breaking feeling as you were turning it. Valves rarely totally break like that. But it can happen. My guess is you most likely have it in the wrong position. If it is broke, you'll have to turn the water off further up the line if you can or turn all of the water off if there isn't another shut-off valve to cut water pressure to the line. I would think there should be another shut-off valve some up the water line.

- Q: I have a question about my car. The mechanic told me that my valve body needed to be rebuilt. However I read that the valve body is a sensor that tells the car when to shift gears. Now my car is a semi automatic so I can shift gears myself! I was wondering if someone could tell me whether it was still necessary to rebuild it if I'm going to be shifting gears myself? I just don't want to mess up the valve body even more and eventually have to get a whole new transmission!

- Its an electrically shifted automatic. The valve body is not a sensor it is the valving system that sends fluid to different parts of the transmission to shift gears. The solenoids on the valve body move the valves dependant on what the computer tells it to do. The paddles or shifter you have do not go to the transmission but to the ECU and the ECU decides what to actually do with the transmission. It does not matter if you shift it or let it do it its self if the transmission is going out it needs work or rebuilt, it WILL fail sooner or later and leave you stranded. So you either need to get it rebuilt or get another transmission. If you drive it until it fail you will need another unit, if you fix it now yours might be able to be saved.

- Q: Hello, I have a 1990 BMW 525i.I would like to paint the valve cover where the BMW was written between a set of lines.I think I require a heat resitant paint for doing this.Can anyone advice the brand which will be best suited for this job.Is it advisable to chrome plate the valve cover.?with regards,natarajBahrain

- you do need heat resistant paint, you can chrome if you want to, bm dealer can advise best brand of paint

- Q: 1998 camaro3.8L v6sometimes when i start the car, it makes this loud ticking noise that goes with the RPMIm pretty sure its the valve, anyone know how to fix it, and how much it might cost?

- HI what you are hearing is not a valve but a lifter... MAYBE... Here's a couple of things that well make it tick. 1) an exhaust manifold gasket leak well sound like a ticking lifter. ( if the noise goes away after the car warms up it might be this gasket.) 2) a bent push rod well make a lifter tick ( as the tolerances would be off) 3) a bad lifter well make a ticking sound. If it is indeed a lifter then best leave it to a pro.. As the intake would have to come off to replace ALL the lifters (you can't buy just one). If its a push rod just the valve covers well have to come off.. to isolate the sound you can use a long piece of hose 3 ft. or so. hold one end to your ear and move the other around the motor compartment and see if you can tell if the sound is coming from inside the motor (lifter), inside the valve cover (push rod) or outside the motor exhaust gasket. good luck tim

- Q: hi ihave a 2001 1.4 civic (6th gen) has anyone got any info/reviews on the following mods: powerboost valve, denso/splitfire spark plugs(which one would be better) and splitfire ignition leads.

- While I'm not familiar with the power boost valve specifically, it looks similar to a rising rate fuel regulator which is used more for forced induction applications like turbocharging and supercharging. If you were to install this on a relatively stock car you would risk running an extremely rich mixture that the stock ecu would be unable to compensate for which in turn could cause damage to your engine. The stock fuel regulator that currently sits in your car is more then sufficient enough to keep up with simple bolt on parts and shouldn't need replacement unless you are planning on doing true engine work or forced induction. As far as comparing different companies' spark plugs and wires it would really be a matter of splitting hairs.

Send your message to us

High-performace pipeline ball valve DN3 inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords