High-performace pipeline ball valve DN 4 inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of pipeline ball valve

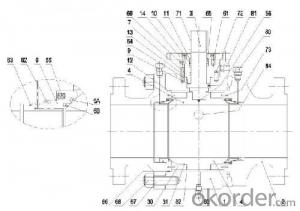

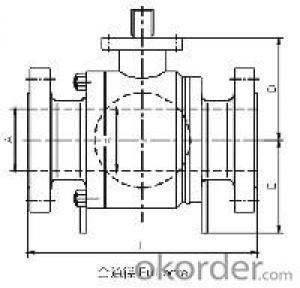

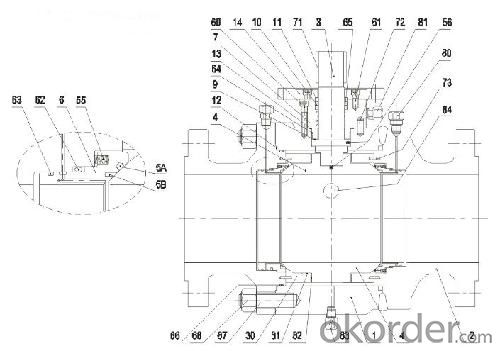

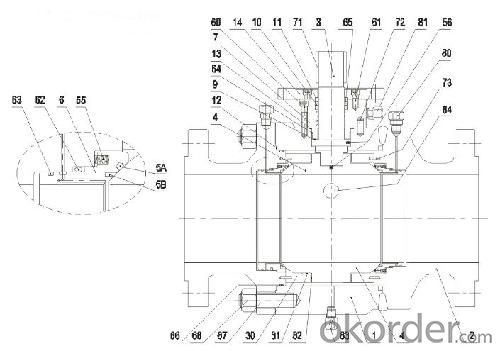

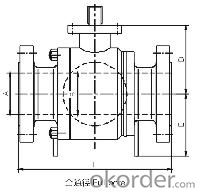

Body of high-performance pipeline ball valve is forged structure.The connection type for body and vice-body can be BB(bolted connection)and WB(welded connection).The WB(welded connection)and the LWB(Fully-welded extended stem)structure isadopted for buried ball valves,as shown below.

High performance pipeline ball valve series has the feature of strength,high perfect sealing,maintenance-free,long life and so on.The production of this series ball valve adopts the international advanced ball valve design and manufacturing technology,selects high-quality materials in accordance with the standard selection of materials and combines with advanced materials forming forging technology.At the same time,with the years of ball valve design and manufacturing experience,the use of advanced processing and manufacturing equipment and production and processing technology,through the first-class inspection and testing equipment and instruments,perfect quality assurance management system and excellence in the production of high-performance philosophy can ensure the quality of valves.This series of valve has the performance of a high strength,defect-free forging body,excellent sealing performance,even at maximum pressure difference(full pressure),it will still be able to ensure that seal without leakage,after frequent switching action to realize a safe usage in the transportation of oil,natural gas,coal gas,and other special medium transportation pipeline.

Performance & Dimensions of pipeline ball valve

Standard Criteria | ASME/ANSI/API customize |

Pressure Rating | 1.6 Mpa 2 Mpa 5 Mpa 8 Mpa 10 Mpa 16 Mpa 25 Mpa 42 Mpa |

150 Class 300 Class 600 Class 900 Class 1500 Class 2500 Class customize | |

Valve Size | 50 mm 80 mm 100 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 550 mm 600 mm 650 mm 700 mm 750 mm 800 mm 850 mm 900 mm 1000 mm 1050 mm 1200 mm 1400 mm |

2 inch 3 inch 4 inch 6 inch 8 inch 10 inch 12 inch 14 inch 16 inch 18 inch 20 inch 22 inch 24 inch 26 inch 28 inch 30 inch 32 inch 34 inch 36 inch 40 inch 42 inch 48 inch 56 inch customize | |

Actuator | Electric Handle Hydraulic Pilot-hydraulic Pneumatic customize |

Connection | Butt Welding Flange RF Flange RTJ customize |

Medium | Gas customize |

Medium Temperature | -29~150℃ -46~150℃ customize |

Application Fields | Electricity Petrochemical Power Station customize |

Component Materials of pipeline ball valve

1-Body Material | A105 A350-LF2-M customize |

2-Bonnet | A105 A350-LF2-M customize |

3-Stem | 4410+ENP customize |

4-Ball | A350 LF2+ENP A105+ENP customize |

5-Material of Valve Seat | fluorine rubber customize |

5-Seat | Nylon PTFE peek DEVLON customize |

6-Seat ring | A105 ENP+A322 4140 customize |

7-Packing chamber | A322 4140+ENP A105 customize |

9-Stem gasket | RPTFE customize |

10-Packing | graphite PTFE customize |

11-Packing gland | ENP+A350 LF2 ENP+A105 customize |

12-Body gasket | Stainless steel+graphite customize |

13-Gasket | Stainless steel+graphite customize |

14-Top flange | A105 A350 LF2 customize |

30-Supporting board | A105 A350 LF2 customize |

31-Gasket | customize |

55-Seat spring | B637 Inconel X750 customize |

56-Anti-static spring | B637 Inconel X750 customize |

60-Bolt | A320 L7 A193-B7 A193-B7M customize |

61-Bolt | A193-B7 A193-B7M A320 L7 customize |

62-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

63-Fire-safe ring | flexible graphite customize |

64-O-ring | hydrogenated nitrile butadiene rubber fluorine rubber customize |

65-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

66-O-ring | fluorine rubber hydrogenated nitrile butadiene rubber customize |

67-Bolt | A193-B7M A320 L7 A193-B7 customize |

68-Nut | A194 2HM A194 4 A194 2H customize |

71-Key | A322 4140 customize |

72-Locating pin | A322 4140 customize |

73-Locating pin | A322 4140 customize |

80-Seat injection valve | WCB+ENP customize |

81-Stem injection valve | WCB+ENP customize |

82-Bearing | PTFE+Stainless steel customize |

83-Drainage valve | Stainless steel customize |

84-Vent valve | Stainless steel customize |

85-Actuator | customize |

90-Plate | Stainless steel customize |

Standards Applied of pipeline ball valve

Design Standard | API 6D customize |

Connection Standard | ASME B 16.25-2007 ASME B 16.5 ASME B 31.4 ASME B 31.8 DIN GB、GB/T JB、JB/T JIS customize |

Test Standard | API 6D customize |

Face to Face | API 6D customize |

Pressure-temperature rating | ASME B 16.34-2004 customize |

Marking | MSS SP-25 customize |

Images of pipeline ball valve:

FAQ of pipeline ball valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Model 28 BS 12.5 HP engine intake valve sticks. Please advise.When under a full load like tall grass, it runs great, but when the load is not as heavy, the intake valve sticks open, spewing gas back through the carb and mis-firing.

- Are you sure that the valve is sticking or is the carburetor flooding?

- Q: okay, where the dome is on the head (where the flat part of the valves sit) the intake is uneven and the air+gas mixture escapes threw the open space when the piston goes up into the compression stage, and ignites shooting flames out of my exhaust port. the space is small but u can see light threw it when the valve sits there. Would some kind of Liquid metal work? or gas+heat resistant epoxy work to take the place of the missing space? I would file it but that would not be precise and time consuming, and i would buy a new head for $150, but the dealer doubles that price! and no way am i paying $300 for a new head. any comments would be well appreciated!

- Get a valve job - cut the valve seats and lap the valves.

- Q: the pressure relief valve on the top of the tank needs replaced

- strictly speaking there are qualifications for this kind of repair hot pressurised water can be very dangerous

- Q: I'm looking for a valve that can be electronically controlled to open and close with a diameter of 1.5'(inches) to 2'(inches) and this valve must be able to withstand 20psi. Any websites or listings of stores I can go to would much appreciated. Thank you

- Any industrial plumbing supplier will either have these in stock or be able to obtain them for you. There is not much point in giving you addresses without knowing what country that you are in.

- Q: All i see is portal and l4d Valve must of discontineud Half life. Its been 6 years they should at least tell us the making the game. I guess this means half life is dead and the last one is ep.2 why valve? why? tell us its coming to xbox 360!

- ok at first you may play 0.5-existence episode a million and 2. Now on your question: the boys at valve in basic terms make video games for the money and presently, they have adequate. in the event that they sense that they are working low on funds, they're going to think of of transforming into one. Now the explanation why they make different video games and not HL3, is that on the HL2 episode 3, the storyline have been given complicated and making th continuation is tough and so, they do no longer even think of of transforming into it. so they only think of of transforming into yet another game and getting numerous funds. working example, Counter-Strike international Offensive. Its the comparable game, in basic terms with extra useful photos, new fashions, some new maps and... yet its nonetheless the comparable Counter-Strike we performed earlier. and people fall for it! maximum people presently do no longer probable care relating to the storyline, gameplay and stuff, they only care if its new or has stable photos. So via making video games like that, or the source ones, they get the money they like without even questioning approximately 0.5-existence 3.

- Q: I have tried to adjust valves of Suzuki Intruder VS400 but they still tapping..so how to adjust them in the right way?

- You know what they say. if you cant hear the valves tapping, their doing damage! but it can be too loud. Make sure that your cylinder is at top dead center for the valve your adjusting. Then You need to know what feeler gauge is right but you probably already know. Make sure when you adjust them that they make the feeler gage drag slightly when you pull it out. If you have a twin you need to make sure that each cylinder is top dead center when you adjust the valve for it.

- Q: I own a 2wheel drive 2003 Hyundai Santa Fe 4cly. The engine light was on the code P0401 came up which is the EGR valve. I had it changed out the engine light came back on after I had made it almost home. I took it to auto zone same code came up that made me take to the shop for repair in the 1st place. Ugh. Please help! What's the problem???

- My vehicle is throwing a P0401 code. I was going to replace it, but instead I am going to clean it and replace it. I know the mechanic will want to replace it and charge me well over $100 (I'm seeing the part go for around $52-$55). THe car was recently serviced with the valve cover gasket replaced.

- Q: what is the difference between the pinch valve and gate valve / knife valve? If someone can help me explain / show me the complete structure of pinch valve and the way it operates, thats better

- a pinch valve has a membrane (or sleeve) inside the valve. When the valve handle is screwed down the membrane is pinch closed. This type of valve is good when the flow needs to be finely controlled. It is also good for slurry (abrasive) flows, as the membrane can be replaced when worn. Gate valves are less effective when the flow must be controlled. They are not used in slurry applications at all, as the gate will be quickly worn away. Knife gate valves can be used in slurry, but are generally totally open or totally closed. The valve must be installed the correct way around, as when closed the weight of the product against the knifegate helps seal the valve. If you have the wrong way around it will tend to leak.

- Q: My valve covers are leaking how do I take the intake off my v6 firebird?

- type into search box how to remove valve covers how to remove valve covers 1995 firebird pretty easy really just like ten bolts not tight and just have to remove what ever is in way of getting them off many times not much to it really only tip is to say clean old gasket off good and do not over tighten when repalcing they just hand tight really

- Q: i have been told that a bad EGR valve (exhaust gas recirculation valve) could cause a car to buck or hesitate in mid range speed at low rpms, thats what my car is doing. i work at autozone and i used our code reader and there was a code that stated EGR flow malfunction anyone else have this problem ever? please help me! i dont wanna spend the $120 if i dont need to!

- There is a device called the transducer that connects to the EGR system via vac lines that doe's have a electronic plug on it that could show up under codes as if the EGR valve is faulty but isn't.If the EGR valve has a electronic plug on it then it could be that it's faulty. Hope that helps and best of luck.By the way I ran into that same problem and it was the transducer.Keep in mind that at the big do it yourself auto wreckers you should be able to find several of either of those parts.

Send your message to us

High-performace pipeline ball valve DN 4 inch

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords