High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

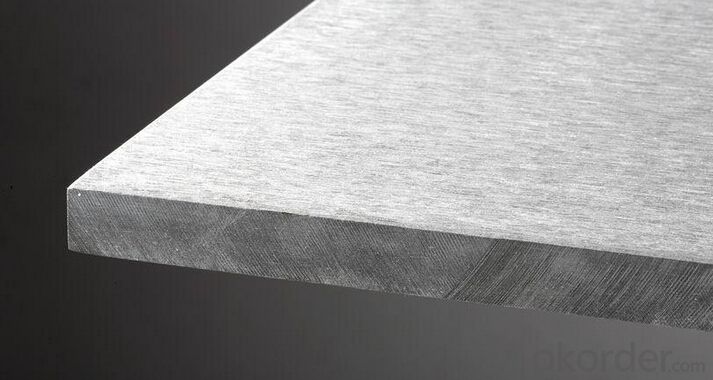

Fiber cement board, using high quality fiber and mineral substances as main content,was made with forming by advanced technique & technological process & through high temperature & high pressure maintenance & special treatment.

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q: Production of fiber cement board copy method has what characteristics

- The fibers are oriented in two-dimensional plane orientation, and the direction of the fiber is mainly in the direction of the main stress of the plate. Through other means of subsidies, can make the fiber arrangement direction to meet the requirements of different products.

- Q: Really stone paint the external walls, with ordinary cement board how to deal with the base, what materials to do

- However, it should be noted that grassroots conservation takes a long time, and the winter and summer conservation period is different, generally longer in winter, while the summer conservation period than the winter probably to about half.

- Q: I am buying materials for the shower pan and all the other things I need but am not sure what thickness of cement board to use for the shower walls. I am covering it with tile, if that matters. Thanks

- Use Hardibacker and seal the seams with tape and thinset. Use thinset to set the tile using 1/4 spacers. I have used and recommend that you use a tile sealer to seal the slate prior to grouting and to use epoxy grout. The grout is more difficult to install but requires no sealers which need to be redone at least once a year in a shower and is well worth the initial time and effort. Be sure to read and follow the directions on the grout bags to ensure a uniform color and good grout set. MT C

- Q: Can you glue glue with glue?

- As a waterproof coating use: according to the benefits of clay: water = (2.5-3.0): 1 ratio to reconcile, stirring for ten minutes, you can brush, require thick and uniform, not missing, to be on the road after curing, Brush the second or third, each time about 1.0mm thickness, (1.0-2.0) kg / m2; for some special requirements of the site, can be used glass fiber cloth or non-woven to enhance the use of "a cloth Two coated "" two cloth three Tu "process construction, the thickness of about (2.0-2.5) kg / m2.

- Q: Home studio decoration, do noise wall, is the effect of good gypsum board or cement fiber pressure plate effect is good

- Fiber cement board), the main raw material is cement, selected minerals, by the high temperature autoclaved autoclaved, waterproof performance, can be used as a bathroom partition, or outdoor roof roof, or external walls Board can be in the long term

- Q: Do you have a living room with a cement board?

- Living room ceiling with gypsum board, cheap, simple construction. Can do all kinds of modeling.

- Q: the durock cement board is 1/2 inch and the drywall is 5/8 of an inch...So the shower wall is about an 1/8 of an inch recessed intothe wall. What can I do to fix the situation without redoing anymore walls. If I butt up the bullnose tile against the drywall about half of the tile's thickness sticks out...actually looks ok. I don't know if i should try to make a gradient from the drywall to the tile. There are also some gap between the two types of boards.....fill it with mortar?

- O.K. in this situation I will usually float this area , in other words the same way u float sheetrock , but I use mastic instead of gypsum compound.

- Q: I want to cut off a lip of about 1/8 by 1/2 to accomodate the upper lip of a tub. I plan to do this with several passes of an abrasive wheel in a circular saw set to 1/8. My question is will I be able to machine the board like this or will I get a crumbling mess? the Hardiback is 1/2.

- Hardibaker peels like an onion in layers. We use it half thick often and we just cut it to size and then using a razor knife pushed in between the layers and pull them apart like opening a peanut butter sandwich. This may help you. If you run that saw on the line where you need the lip to start on the board then use your knife to split the layers and peel them down to the cut you made. This may be an easier solution then eating away the excess material a little at a time. Good Luck.

- Q: What is the exterior wall of a light steel structure house?

- Fire, insulation, decoration in one of the professional insulation board Environmental protection without pollution, insulation, decoration, to avoid the cracks caused by the external wall of the external wall insulation caused by local shedding, and has a diversified color, convenient construction and many other advantages.

- Q: Hi i want to know if Durock cement board has zinc or lead. Because I made a aviary in my backyard where i know have my lovebirds and some have started giving me sign of lead/ zinc poisoning i would like to know if Durock has it and if it affects my birds thank you.

- If your birds are Parrot like Budgies etc , they are for ever nibbling at wood or anything else., Do you know the signs of Lead poisoning,Paralysis being the main one. Durock does contain minute particles but have you considered that it could be Mice droppings or mice urine contamination on their food as the symptoms are similar. Your birds must be actively eating the cement board, which you will be ble to see by the damage to the board. Otherwise you must contact a vet asap. Avian Care Consultant

Send your message to us

High Density Fiber Cement Board Prices for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords