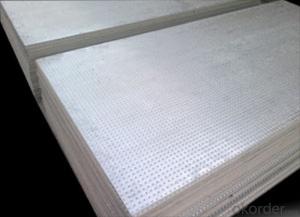

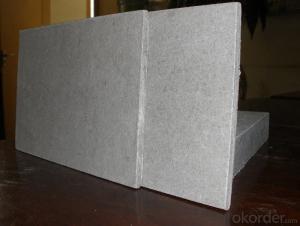

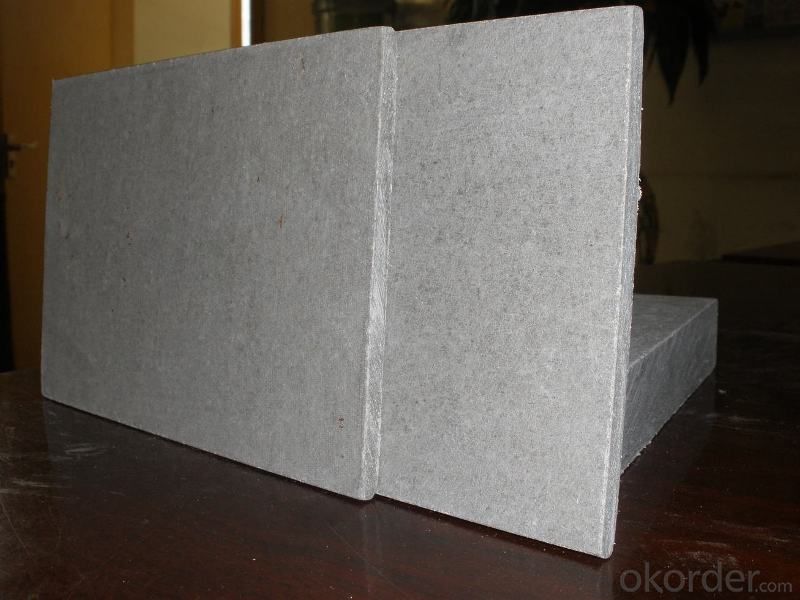

Silicate Board Tiles Waterproof Calcium

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

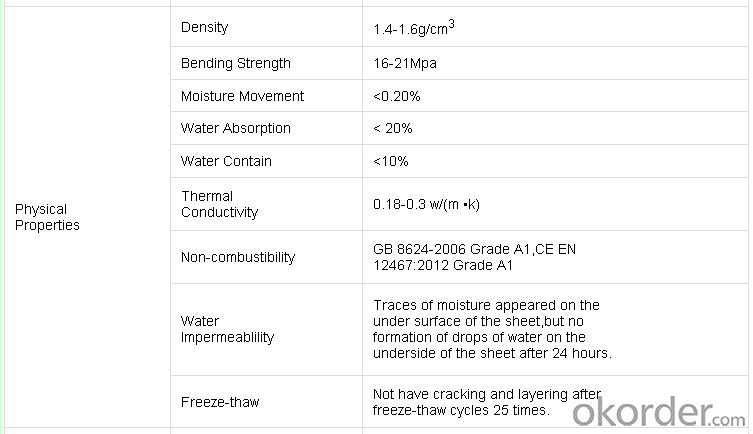

Specification

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

Images:

- Q: Will the reinforced concrete cement board be soaked in water for a long time?

- If the thickness of the protective layer, concrete strength grade does not meet the specifications, will certainly. Improve the strength of concrete grade, protective layer thickness should be reasonable, the use of waterproofing agent (no more than 5%)

- Q: Glass fiber reinforced cement (GRC) board is what

- GRC is glass fiber reinforced cement products. He is composed of anti-alkali glass fiber and low alkalinity cement composed of a new type of hydraulic composite material, its main features are high strength, crack resistance, fire resistance, good toughness, not afraid of cold, easy to shape, can be made into thin, , The shape of a variety of complex building components and products, in the civil construction of agriculture, animal husbandry and fishery and environmental art and other fields have a wide range of uses. GRC Finished material is made of this composite material such as: GRC European-style components, high-strength GRC curtain wall panels, etc.

- Q: Adhesive method of cement board and cement wall

- 1 , Repair screw holes. When repairing the surface of the screw hole, try to use the cutting cement board powder, with the yarn to filter out the fine powder At the end, plus building 107 Glue, stir and mix, and finally fill hole. (Also available tiles fill filler hole) The 2 , To be dry hole after the place, with sandpaper gently polished cement board surface, remove the surface of the plate stains. Brush the surface of the company Protection products: FOREX Cement board protection agent, brushing 2-3 all over

- Q: I'm making designs for a house I want to build. Initially I wanted to build the house out of primarily concrete, however because of where the house is going to be going, it's not really plausible to get that amount of concrete out there to pour at once (it would be extremely difficult to get a truck out there).So my next consideration would be to build an otherwise traditional frame and instead of using drywall on the inside, I would use cement boards to panel the walls, and go for a clean, future-industrial look. I was also intending on doing something similar to the exterior.However, cement boards obviously weigh significantly more than typical drywall panels, and my main concern is whether or not a regular wood frame would be able to hold that amount of weight. So would that pose a significant issue to the extent that I should also consider using steel for the entire frame, or at least as a support system, or should wood be able to hold up just fine?

- Plaster in the (3) layers they used to install on homes years ago is just as heavy as cement board-if not heavier. No worry about wood being able to support the cement board. As far as your house of concrete - you need to do some serious pricing of materials and labor for all aspects of your dream home. First of all you need to price lots or land, then cost of site work such as driveway, Tap fees for water,sewer, or you may need septic system if rural area. If you choose a building method that is off the wall - you should be prepared to pay $200-$300 or more per square foot.

- Q: Bathroom with cement board hanging the top, now open the hole to install the lights, so hard to open Oh ,,, which big god to help me out of ideas? Thank you!

- 1, first clean the bathroom floor, in the sewer around the corridor around a clean, 2, buy high-molecular quartz sand beauty mud (waterproof type comes with a bag of 40 or so), please muddy wet floor and then approved flat. Sprinkle water 2 to 3 times before completely dry, although the glue does not dry like cement quickly, sprinkling is also necessary.

- Q: Can the cement do not dry?

- Yes, as long as the cement surface to ensure the smoothness of the surface roughness and verticality can be directly sprayed.

- Q: What is the average price for hardieplank(cement board) installation?

- Anywhere from $10 to $15 per square foot depending upon how cut up it is. Large walls with not many cuts - $10. Small expanses with lots of angles and cutting - $15 of more if really complex. This includes the hardie product, the water proofing and the fasteners.

- Q: This is when you are installing tiles over existing cement patio. Idk if it's a board, it seemed bendable. I saw it on HGtv And I can't remember what it's called

- Made by Schluter tile systems and I believe what your referring to Ditra, Flexible orange mat. Any questions you can e mail me through my avatar and check my qualifications there, GK

- Q: The roof of the cement board everywhere cracked, how to do

- Roof cement board cracks, must wait until the sunny morning to do waterproof before the roof, it is recommended to use rigid flexible combination of flexible waterproof material plus rigid material effect is the best. Flexible materials to coil, linoleum-based.

- Q: more upscale. is this true? is there a big difference in the look? how do they differ in appearance? whats so great about it?

- Vinyl siding, especially the cheapest grades have a plastic appearance. It's inexpensive and it doesn't dent like the old aluminum siding. It can be maintained with an occasional spray of the hose or power washer. It's usually a desireable selling-point --maintenance-free -- Cement board is more costly and requires painting. It does allow for changing the color of your house for the price of a fresh coat of paint. It's durable and long-lasting. It's usually molded with a wood-grain pattern and It has a noticeably more upscale appearance than vinyl. Some local ordinances prohibit vinyl siding due to its cheap appearance.

Send your message to us

Silicate Board Tiles Waterproof Calcium

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords