Fiber Cement Board with Good Quality and Prices

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

Our fiber cement board is made of high-grade cement and modified material, reinforced by natural fiber. Being processed by high pressure and temperature advanced technologies. It’s a new building material with excellent performances.

Product Advantages:

Standard Size: 1220*2440mm (W*L)

Thickness Range: 5mm~30mm

Packing: Pcs/Pallet

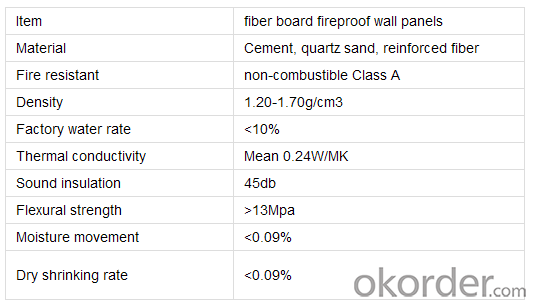

Parameters:

Density: 1.2~1.5g/cm3 (medium), 1.5~2.0 (high)

Water Absorption: ≤30% (medium density), ≤25% (high density)

Non-combustibility: Non-Inflammability Class A

Wet Expansion: ≤0.25%

Bending Strength (Dry/Wet): 20/12 MPA (medium density), 24/14 MPA (high density)

Main Product Features:

Fire Proof & Insulation;

Waterproof and Moisture Proof;

Thermal & Sound Insulation;

High Strength & Light Weight;

Economical;

Good Looking & Easy Installation / Replacement;

Safe & Harmless;

Product Specifications:

Images:

- Q: Cement board spray really stone paint

- It is recommended to use the steel structure to do the foundation, first by 4.5 meters high 5 meters wide welded into the door type, and then use the GRC production of cement board (which vertical laying 6 PCT or 8 PCT steel, solder joints) welded to the steel structure, the surface Treatment is waterproof putty and spray really stone paint!

- Q: Fiber cement board and glass magnesium board how to distinguish

- Ingredients: glass magnesium board for the magnesium oxide, magnesium chloride chemical reaction products, is one. Cement fiberboard is a cement, yellow sand aggregate, is a physical reaction.

- Q: I have an existing hardwood floor that I want to tile over (it's not in good condition). Can I put cement board then tile directly onto the hardwoods or do I need plywood on the hardwoods then cement board then tile? I don't want the floors to be 2 thick in addition to the hardwoods.

- Can you explain better? What do you mean when you say the hardwood is not in good condition? Uneven?Decaying?Quick answer if the hardwood is either, youre better off taking it out and starting with a good base.

- Q: I am in the process of purchasing a townhome and I am looking to tear up the existing 12 ceramic tile that covers the entire main level... an area close to 600 sq. ft. to make way for laminate flooring. Thinset has been used to bond the tile to the cement backer board, and the backer board has been screwed to the wooden subfloor. There is also some sort of adhesive/mortar bonding the cement board to the wooden subfloor. What tools will I need. Are there any techniques that would make it easier? Would trying to remove the cement board damage the subfloor? If so, would it be acceptable to repair damage with some sort of floor leveling compound?

- big *** crow bar, thats how i did my kitchen, yep it sucks. you can get a nice one for this in the garden section its made for digging holes but has a nice flat section, for what I dont know but it teats a floor up,

- Q: Bathroom with cement board hanging the top, now open the hole to install the lights, so hard to open Oh ,,, which big god to help me out of ideas? Thank you!

- To do a strict waterproof construction of the ground after the formation of the protective film will be flexible waterproof waterproof (this waterproof performance is particularly good, the problem is completed after the surface is too smooth and bad tiles), the walls painted ordinary bathroom waterproof treasure, although the waterproof performance of ordinary, After finishing the rough surface favorable tile paving

- Q: I'm laying slate tile over linoleum that was installed about 6 months ago....the linoleum is in very good condition, very smooth with no rips or lifting. I've done some research and figured I could put down cement board and then lay the tile on that. The floor under the linoleum is cement. Is there a special drill/special screw necessary to attach the cement board to the cement foundation?

- Your best to remove the vinyl but it is a LOT of hard work and truly not needed if it is down tight and no air pockets etc.. No cement board is needed at all . A wasted expense.You really can rough up the vinyl w/ belt sander, and tile over the vinyl w/ proper thin set.. Allow an extra day or two to let the thin set dry since moisture has no where to go.. Make sure your use a damp sponge to wipe off back of slate since the way its cut it leaves a residue on the back ( dusty) that will not let thin set bond properly.. A gauged slate is easy to set just like any tile its the ungauged slate you ll have to be more carefull with.. Seal the slate at LEAST once before installing or thinset and grout may stain or be almost impossible to remove GL

- Q: What is the prc in the building?

- PRC Fiber cement board flame retardant foam concrete

- Q: Installing a shower in my basement, and am framing around a fiberglass 36 square shower base. should I put it flush against the frame and then attach cement board (it will overhang) or leave room to slide cement board between base and frame? Thanks!

- The framing goes tight to the shower pan, and the cement board goes down to the lip of the pan, but not over it. IMPORTANT: do not run the cement board over the lip or this will cause a bow at the bottom all the way around. Your tile will run down to the shower base. If you ran the cement board behind the shower pan the lip would stick out and when you tiled, the tile would be pushed out as described at the bottom row. I hope this makes sense to you.

- Q: What kind of cirrcular saw blade do I use to cut cement board?

- You can score and snap straight cuts. But this will not work for inside corner cuts. Or you can purchase a blade specifically for cement board....they are pricey. The option is an inexpensive carbide tipped blade.....about $8-12 and after a dozen or so cuts throw the blade away. You will create alot of dust using the circular saw. Another option for smaller projects is using a jig saw with a bi-metal blade....creates alot less dust.

- Q: i built a pair of cubed 2x4 tables,can i use cement board on top?then tile?

- With mastic cement you can stick tiles right to a wood surface providing it's flat. I used 6 floor tiles with mastic on cabinet grade plywood for our kitchen. It's lasted 17 years now. Mastic comes in plastic containers already mixed......you just trowel it on and stick your tile.

Send your message to us

Fiber Cement Board with Good Quality and Prices

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords