Waterproof Calcium Silicate Board Tiles Calcium Silicate Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

Main Product Features:

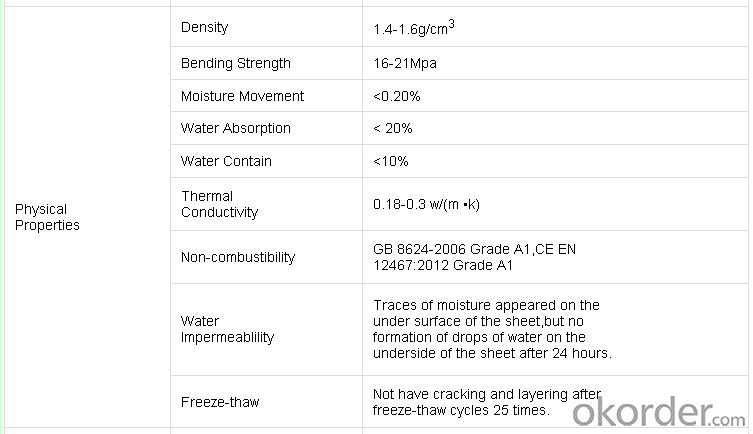

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: What is the material cut off both the fire and cheap

- The so-called Eide plate is a fiber-reinforced silicate plate (fiber cement board), the main raw material is cement, selected minerals, by the high pressure autoclave pressure. Ette board is a fiber reinforced cement plate with Fireproof. Good soundproofing, environmental protection, etc. It is 100% non-asbestos, and its waterproof performance is particularly superior to the bathroom for use as a partition, or an outdoor roof roof, or an external wall can be used in long-term damp The environment to maintain stability and stability.

- Q: Can v board be glued directly on the wall?

- In the wall covered with a grass-roots level, commonly used is 3MM plywood, woodworking board, a good point is the fire glass magnesium board. With nails to nail them on the wall, and with a sandpaper to clean the board.

- Q: Want to know the cement fiber board recipe and check your product for compliance

- Cement fiber board is based on siliceous and calcium materials

- Q: What is the quota of cement board

- Cement pressure plate does not have a special quota, and its installation process with the same gypsum board, you can use the gypsum board fixed sub-head, modify the name and price can be.

- Q: how can you tell the difference between asbestos and cement board?

- You have to have it tested. The difference could be as little as 2% asbestsos and they will appear the same.

- Q: The difference between cement fiberboard and cement pressure plate

- Fibreboard' name emphasizes the reinforced material 'fiber'; 'pressure plate' name emphasizes the production process, the use of presses on the board green pressure, squeeze out the water and compaction, improve the board density and strength. 'Cement fiber board 'Is a more traditional name, but in recent years is also known as' cement pressure board'.

- Q: I have a friend who owns a house who believes it was built in 1968. The basement is in immaculate condition-- completely dry. The walls are poured cement and you can see where the forms were taken off the wall after it was poured. My question -- did they pour walls back in 1968 or was cinder block the building material used? I think the house was renovated within the last 15 years. My friend and I are baffled. Thanks!

- Yes (and as 2 other people already said) Concrete was in use long before then, in fact it is very much in use then, also if the walls are in real good shape that means they didn't pour cheap and let it cure long enough before moving on! Pour cheap basically means that when pouring concrete you mix several ingredients and if you cheapen the mix (more for non load bearing walls) or don't let it cure long enough (which final curing takes years) (see sources below for better explaining) Another way to find out if they re-poured 15 years ago is to look for support beams that look like they have been clamped onto!

- Q: What is the difference between cement calcium silicate board and cement fiberboard

- Silicon calcium board, also known as gypsum composite board, is a porous material, with good sound insulation, thermal insulation properties, in the case of indoor air humid to attract water molecules in the air, air drying, but also the release of water molecules can be appropriate Adjust the indoor dry, humidity, increase comfort. Gypsum products are also special fireproof materials, in the flame can produce endothermic reaction, while the release of water molecules to prevent the spread of fire, and will not break down to produce any toxic, aggressive, suffocating gas, will not produce any Combustion or flue gas.

- Q: Is it okay to install ceramic tile on greenboard, or is cement board necessary?

- If the top layer of plywood is treated then there is no reason whatsoever to apply water proofing. If it isn't treated then there is always a small risk that large amounts of mold could develop in the plywood, but it is a small risk. I would pull up the cement board and put roofing felt under it. Or if I didn't want to take the time for about 80 dollars I can pick up a spray on waterproofing layer to the cement board that most tile flooring stores should carry. Tile membranes are good product, but somewhat expensive to use. Grout is sealed to protect the integrity of the grout and no other reason. A small amount of floor movement and water will have a direct path past the grout.

Send your message to us

Waterproof Calcium Silicate Board Tiles Calcium Silicate Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords