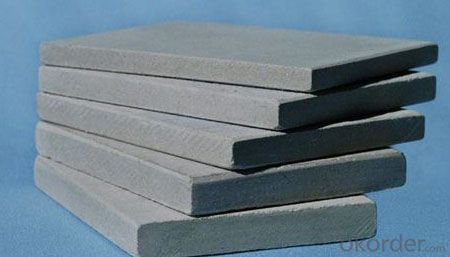

Reinforced Fiber Cement Board Usd For Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

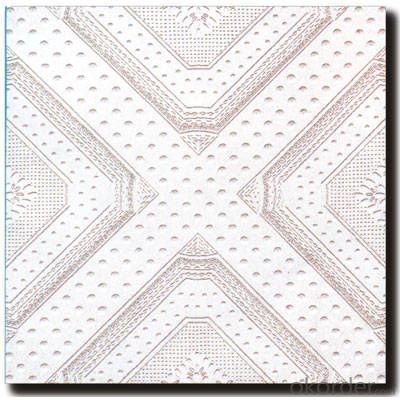

UV Siding Fiber Cement Board

1. Cheaper Than Marble, Bigger Than Ceramics

2. High Density Fiber Cement Board As Substrat

UV Siding Fiber Cement Board

1. Cheaper Than Marble, Bigger Than Ceramics

2. High Density Fiber Cement Board As Substrat

Ideal Substitute of Marble or Ceramics, Because of The Low Price, Lighter Weight, and Bigger Size of Our Product.

Product Advantages:

1. High density fiber cement board as substrate.

2. UV painting on the surface, Various of Patterns Includes Marble, Wooden, and Solid, Glossy and Matt for Every Pattern.

3. For Interior Wall and Ceiling Only.

4. Widely used in Hospitals, Hotels, Schools, Offices, Subways, and Laboratories.

Fireproof: "ASTM-E84 FLAME SPREAD INDEX" = 0, STANDARD <= 25

Smoke: "ASTM-E84 SMOKE DEVELOPED INDEX" =5, STANDARD <= 25

Weather Test: "ASTM-G155" = 4, STANDARD (3,5)

Main Product Features:

Standard Size: 1.22M*2.44M / 4'*8'

Thickness: 6MM

Weight: 30Kg

Surface Hardness: 3H

Product Specifications:

(Item) | (Unit) | (Result) | (Standard) |

(Density) | g/cm3 | 1.6 | 1.4<D<=1.7 |

(Weathering Test) |

| 4 | 3<=W<=5 |

(Flexural Strength) (Dry) | MPa | 19.5 | >=18 |

(Flexural Strength)(Saturated) | Mpa | 16.5 | >=14 |

(Water Absorption) | % | 19.6 | <=25 |

(Wet Expansion) | % | 0.176 | <=0.23 |

Images:

- Q: The difference between asbestos cement fiberboard and cement fiberboard

- Non-asbestos cement fiberboard and cement fiber board is the main difference between a main inside of the fiber with asbestos, one is useless, because China is a major producer of asbestos, Europe and the United States did not, so Europe and the United States said that asbestos harmful not to use, Of the product imports, but the domestic scientific research to confirm the usual use of asbestos are chrysotile, the human body is not harmful

- Q: 911 polyurethane brush in the cement board is what is the bubble

- Wood paint after brushing the phenomenon of blistering, often before brushing, can not be mixed with wood paint and then no longer let it rest for half an hour or so again and again the phenomenon of operation. In addition, in the brushing because of the window and make the wind blowing in the decorative panels, but also cause the phenomenon of blistering. This phenomenon is more trouble, with fine sandpaper to the bubble at the light of the sand level, and then dry with a dry cloth, and then make up the same wood paint. Sometimes fill the paint at the larger color, it must also be the whole face all brush again.

- Q: I'm removing a tile floor and planning to install a hardwood floor instead. I found cement backer board under the tile. Do I need to remove the cement backer board? Or can I install the hardwood on top of that?

- if it was my house i would remove cement board and replace with wood to accept nails, if it is a floating floor you can keep it, just put tar paper doon before floating floor

- Q: Then I have to install marble in replace of this tile. I have laid a lot of ceramic tile but I being told that marble is a real pain in the but. I just started my business and this will be my first big job. Please give me your input. I live in Denver Colorado. Thank you

- Big difference in marble and ceramic of course. You will have to face difficulty as compared to pasting marbles.

- Q: the neighbor has a son and him and his friends constantly makes noise instigating trouble. I complain to the manager, it stops and than starts back up again a week later, so I rather put up something that can help

- Where I used to work we put up Cork Board 1 thick on the entire wall to help with the noise next door.

- Q: I am buying materials for the shower pan and all the other things I need but am not sure what thickness of cement board to use for the shower walls. I am covering it with tile, if that matters. Thanks

- Use Hardibacker and seal the seams with tape and thinset. Use thinset to set the tile using 1/4 spacers. I have used and recommend that you use a tile sealer to seal the slate prior to grouting and to use epoxy grout. The grout is more difficult to install but requires no sealers which need to be redone at least once a year in a shower and is well worth the initial time and effort. Be sure to read and follow the directions on the grout bags to ensure a uniform color and good grout set. MT C

- Q: Would you recommend putting crazy glue in the draft boards locks, or cement?

- When was there ever a non-military draft? I prefer crazy glue because it sounds more fun that cement.

- Q: Want to know the cement fiber board recipe and check your product for compliance

- Add a new type of building material that is made of plant fiber, pulping, picking, pressing, and curing. Nowadays the most popular micro-spectrum analysis method through a variety of micro-spectrum analysis to accurately obtain the exact proportion of each component, access to high-quality formula.

- Q: I have a small 4X2 area in which I need to re-tile. The area now is outdoors and is set inside of a concrete slab. Who ever installed the tiles before installed them like paver's where they backfilled the small area with sand (about 3). My question is can I use durock or another cement board to get a solid surface for tiling or do I need to refill the area with concrete? I don't know too much about concrete work which is why I am looking to use the cement boards.Thanks

- u could thin set the concrete board but u would be better to redo the slap to what is needed and then tile it , cement work is not difficult , Im sure u can get pointers from the big box store or local hardware, good luck !!!

- Q: i am using cement board to cover a wood floor before laying tile. the last time i used it, i cut it with a circular saw (what a mess) dust everywhere. is there a better way??

- sharp utility knife and a strait edge. Score a couple times and break. If the board contains fiberglass mesh, you'll have to cut from the opposite side after its broken and bent 90 degrees.

Send your message to us

Reinforced Fiber Cement Board Usd For Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords