High Density Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Cement Boards) Description

fiber cement board

light weight

water resistant

fire resistant

dimension stable

Fiber cement board

reinforced cement composite panel is a light weight cement product, been compounded of cement,silicate aggregate, polystyrene beads, reinforced mineral mesh fiber , the panel can boast superior fire ,thermal and acoustic properties, as well as being 30% stronger than alternative sheathing material, its resistance to moisture, it can applicable for use in most of construction or renovation project.

2,Main Features of the (Cement Boards)

Basic Uses:suited as an underlayment or backing surface for exterior wall and interior wall

Advanatages:

a-has 2 design for edges,bevel or pressed taper edge,which is convenient for joint.and does not break during transport

b- is approved as a substrate for direct applied finishes,tiles,stone,and thin brick in exterior application

c- us suitable for use in combustible area,which been test under ASTM E84 and 119

d- is highly moisture resistant,and will not rot,disintegrate or swell when expose to water

e-is light weight and high strength,however can be cut utilizing a standard utility knife and staightedge.

Limitation:

a-joints should be treated with alkali resistant fiber glass mesh tape

b-can not use in bearing structure

c-can not use as water tank

3,(Cement Boards) Images

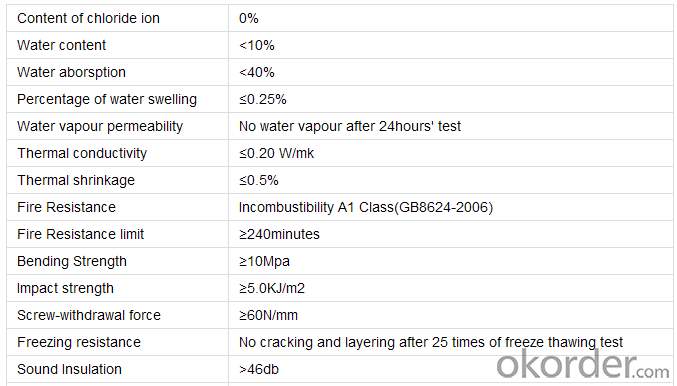

4,(Cement Boards) Specification

5,FAQ of (Cement Boards)

1.Hold by Wooden Pallet

2.Covered by PVC and Bonded with plastic belt

3.Fasten around the corners

4.Mounted in container to protect your purchasing

- Q: I've installed a fair amount of this stuff behind tub-surrounds & showers. I generally use a jig saw with a carbide blade, which promptly goes dull. Any experienced tile workers out there find a better way?

- I am an architect and I have seen tile layers on the jobsites use a table saw or a 7 1/2 circular saw to make long cuts for the cement board with a carbide tip blade (60 teeth per inch) and for small cuts they use a hand jab saw or sometimes those little roto-zip hand tools. I think that the jig saw blades are too thin and heat up and get dull too fast. for the blue board or green board they just score or break it - Good Luck

- Q: Attic with a channel steel structure, covered with aluminum instead of wood multilayer? Is it feasible?

- Do not need such a complex, directly in the steel structure on the shop 20-24MM thick fiber cement board, and then directly to the floor can be, the floor has a moisture barrier the best pad a layer of moisture, one moisture,

- Q: how to install cement backer board behind a bath tub?

- if you installing the backer board for tile then what you do first is staple 4 mil plastic sheeting to the studs around the bathtub area over lapping the seams, install the tub. then place the backerboard on the plastic above the top edge of the tub. buy the screws that are made for the backerboard(not drywall screws). after the backer board is installed, use a nylon joint tape also designed for the backer board and then apply thinset to the joints.

- Q: also how much is luber per board foot cost.

- i think it's like 200.00 peso per sack but the lumber im not sure cuz it depends on the quality of the lumber. And some cements and lumber are changing especially in which places you are living.

- Q: some say lay 15 pound paper what gives?

- It's a cushion -bed for the cement board. Less chance of it cracking if cushioned.

- Q: How to choose their own materials made of steel structure compartment?

- Each have their own advantages, steel structure loft for its construction fast, safe and stable, high strength, widely used in villas, duplex buildings, the need for buildings on the air. Compared with concrete and wood, the yield strength of steel is much higher than that of concrete and wood. Under the same bearing capacity, the steel structure has a small cross section, which is easy to transport and install. Which are conducive to the production structure within the building, but also greatly reduce the structure due to their own impact on the body itself. At the same time steel structure is simple, short construction period, no maintenance. Late decoration is simple. These advantages are conducive to the transformation of the building structure and reinforcement.

- Q: The doors of a cement cabinet can not be mounted directly on a cement board

- When installing the cabinet door, use a 8 mm glass drill hole to punch the screws with a good hinge.

- Q: Fiber cement board and the difference between the water board

- Wooden cement board construction / Miyan cement board characteristics Wood fiber cement board price / US rock cement board price / Yongfeng International Beijing Guangda Sunny Trading Company has always been adhering to the concept of innovation and promotion of architectural style advocates in the domestic market to lead Trend, the latest foreign environmental protection building decoration materials into the country, the gray style to the climax of gray.

- Q: Standard cement prefabricated board load capacity is a square how many kilograms, thank you

- Casting is in the field of mold, bar reinforcement, watering concrete and other construction procedures to do. Compared to the prefabricated system is the overall shape, good integrity, for a pipe through, or irregular shape of the floor is still very suitable, but its processes, wet operations, the site of watering, the construction period longer The The cast-in-place slab is good and the seismic capacity is strong. Generally there will be no cracks, but thinner, if not do noise treatment, will be more noisy

- Q: I'm installing a stone back splash behind my bathroom sink - 16 SF. The wall is currently painted and I want to make sure that the stone and thinset adhere properly. Should I sand the wall with 80 grit sandpaper and apply the thinset/stone or should I put 1/2 or 1/4 plywood down for better adhesion? Perhaps cement board?

- Ideal way is to do a cement board as a backer board but since its in a non wet area,( not exposed to direct water) you really don t have to.Roughing the area up is always a good idea and won t hurt a thing. I d never do a wood backer in a moist and humid environment, It can expand from moisture and break the bond. Any questions you can e amil me through my avatar and check my qualifications there. GL

Send your message to us

High Density Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords