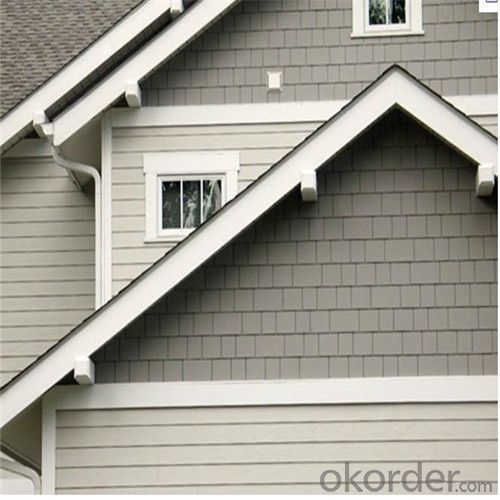

High Density Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Standard Data of the Middle Density Firber Cement Board | ||||||||

| Standard Size | 1220X2440mm/1200X2400mm | Max Width | 1250mm | Max Length | 4880mm | |||

| Thickness | 4-30mm | Density | 1.3-1.7g/cm3 | |||||

| Wet Expansion Rate | ≤0.23% | Water Penetration | ≤25% | |||||

| Forst Resistance | No Layer & no cracks after 25 cycles under freezing and thawing | |||||||

| Incombustibility | Incombustible Class A1 | Radioactivity | Decorative materials Class A | |||||

| Flexural Strength | Air dried Condition ≥18 | Water Penetration | Back side without water drop after 24 hours | |||||

| Saturated Condition≥14 | ||||||||

Application

(1)Cavity Wall for Interior Partition

1.Wet area( restroom,kitchen and basement etc.)

2.High sound insulation requirements area ( pc room,meeting room and hotel etc.)

(2) Light Concrete Grouting Wall

(3) Other Applications

1. Ceiling board

2. Perforated board

3. Aluminum lining boards and insulation barriers for high-speed train

4. Column Coverage

Production Scale and Equipment

We introduced international advanced equipment and technologies. From raw materials preparation to board forming stacking and compressing, autoclaving and destacking are all controlled by strict and efficient production craft. The whole process is full automatic, high efficient and quality stable.

Product parameters

Item | Unit | Requirement | ||||

Medium density | High density | |||||

Density | g/cm3 | 1.2<D≤1.5 | 1.5<D≤2.0 | |||

Water absorption | % | ≤30 | ≤25 | |||

Non-combustibility | GB 8624-2006, grade A | |||||

wet expansion | % | ≤0.25 | ||||

Beding strength | dry | MPA | Strength grade class III | 20 | Strength grade class IV | 24 |

Saturation with water | 12 | 14 | ||||

- Q: This building was previously a school building, with cement block walls..I need to know if I need backer board, or do I just need to fill in the low spots to make the wall flat and level? Also, what kind of thinset do I need for clear glass mosaics?

- You don t need a backer board.. As long as the block is solid and no cracks ( they need to be treated specially) you can go right over the block with a few precautions. The block needs to be clean and smooth. No mortar from the joints and stick out. If the walls are unpainted ( and clean) you can go over them with WHITE and white only thin set.There is no such thing as colored or tinted thin set.And glass tiles call for a strong latex modified thin set If the walls are painted ( and clean) you can use a mastic or the special thin set. Fill in the mortar joints with the adhesive you use. Mastic cannot be used if this is a wet area or going to be a wet area. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: Can the board be replaced by woodworking board?

- Ette board is a high strength, durability and other superior performance of the fiber silicate sheet, with a variety of thickness and density, 100% does not contain asbestos and other harmful substances. For non-combustible A1 grade products. With fire, moisture, waterproof, sound insulation effect, environmental protection, installation fast, long life and other advantages. Commonly used for external wall panels, bathroom partitions, outdoor roof roof, external wall insulation board, interior decoration, smallpox, etc .; can also replace the use of gypsum board in the decoration used as a substrate.

- Q: Can cutting the steel cutting machine cut the cement board?

- Cutting machine: With the development of modern mechanical processing industry, the quality of cutting, precision requirements continue to improve, to improve production efficiency and reduce production costs, with high intelligent automatic cutting function requirements are also improved. The development of CNC cutting machine must meet the requirements of the development of modern mechanical processing industry. Cutting machine is divided into flame cutting machine, plasma cutting machine, laser cutting machine, water cutting and so on. Laser cutting machine for the fastest efficiency, the highest cutting accuracy, cutting thickness is generally small. Plasma cutting machine cutting speed is also very fast, cutting a certain degree of slope. Flame cutting machine for the thickness of the carbon steel material.

- Q: Does the cement board go over the lip of the tub, or does it sit on that lip?

- it goes on top of that lip not over it tile goes over the lip make sure you have a gap between the tub and tile when setting a spacer will do. silicone the bottom row of tile to the tub after the tiles have been set and grout the rest I caulk the cement board to the lip when I install. Its over kill but adds a layer of safety Good luck

- Q: What are the drill bits for the cement board?

- With the impact of the drill bit, but also to use the impact drill.

- Q: do i have to use cement board under tile on a shower wall?

- It would be a good idea to put some water proofing under the cement board. Cement board is only somewhat water resistant. Some types are worse than others. But if you put roofing felt behind the cement board the wall is much more water tight.

- Q: i built a pair of cubed 2x4 tables,can i use cement board on top?then tile?

- depends on what you made them out of. are they strong enough to support the board and tile? if you made them out of kleenex then no. but out of wrought iron, then probably you're ok.

- Q: What are the brands of cement fiberboard

- North China well-known brands: nine Germany, three music Zhejiang area: Dragon, Han Debang, love rich Greek Guangdong has: east, new elements, ete board Tibet: gold special But the manufacturers have the advantages of various manufacturers, please select the appropriate product buyers

- Q: How much is the cement board?

- Cement board raw materials generally do not sell according to the square Zhang, each 1220MM * 2440MM gypsum board than some of your 20-25 look.

- Q: What is the difference between VIVA wood chips and FOREX plum cement board?

- Texture VIVA wood cement board: the same as the positive and negative, relatively smooth FOREX Meilan cement board surface on both sides, rough pattern three-dimensional appearance, fine surface texture delicate.

Send your message to us

High Density Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords