High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering gh Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KGis suitable for the laying of main trunk line of the curves and the orbit of the tunnel can also be used for tower crane and other crane track.Tunnel way, curve way, railway, subway, transportation track, express, etc

Product Advantages:

OKorder's High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

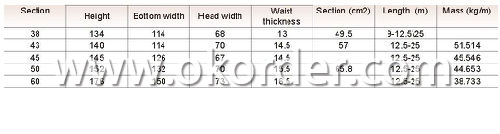

Specifications of High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

Sizes: 38kg, 43kg, 45kg, 50kg, 60kg.

Production Standard: GB2585-81, DIN, AREMA, JIS, BS, UIC, etc.

Material: 50MN, U71MN, 900A, 110A, etc.

Length: 6m-25m according to the requriements of the clients

Invoicing on theoretical weight or actual weight as customer request

Package & Delivery of High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

1. Package: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, size, length, grade, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

Production flow of Steel Heavy Rail

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Can fit in the containers of 20fts the High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG of 6M?

A1: No proble, we can put them into the containers in the form sideling.

Q2: The products are invoicing on theoritical weight or on actual weight?

A2: We can do it in both manners, according to the customers' request.

- Q: Can steel rails be used in railway systems with heavy snowfall?

- Yes, steel rails can be used in railway systems with heavy snowfall. Steel rails are commonly used in railway systems worldwide, including in regions with heavy snowfall. Steel rails are durable, strong, and can withstand the weight of heavy snow loads. Additionally, proper maintenance practices such as snow removal and de-icing are typically implemented in these regions to ensure safe and efficient railway operations.

- Q: How do steel rails contribute to train track stability?

- Steel rails contribute to train track stability in several ways. Firstly, steel is a strong and durable material, allowing the rails to withstand the heavy loads and constant vibrations from passing trains. This ensures that the tracks remain intact and do not deform under pressure. Secondly, the smooth and even surface of steel rails provides a stable and reliable platform for train wheels to run on, minimizing the risk of derailment. Additionally, the precise alignment and secure fastening of the steel rails ensure that trains can travel at high speeds without experiencing excessive lateral movement or instability. Overall, steel rails play a vital role in maintaining the stability and safety of train tracks.

- Q: What is the role of rail anchors in steel rail installation?

- Rail anchors play a crucial role in the installation of steel rails by providing a secure and stable connection between the rail and the sleepers. They prevent the rails from shifting or moving laterally, ensuring the track remains aligned and safe for train operations.

- Q: What are the different sizes of steel rails?

- Various sizes of steel rails are used in railway tracks to accommodate different trains and track needs. Steel rails, commonly used in railway tracks, come in various sizes. The sizes of steel rails are categorized by their weight per meter or yard. Here are some examples of the different sizes: 1. Light rails: For light-duty applications like tramways, light industrial tracks, and underground mining, light rails weighing from 8 kg/m to 24 kg/m are typically used. 2. Standard rails: Also known as "mainline" or "heavy" rails, these are the most commonly used rails for standard railway tracks. They can handle heavier loads and higher speeds. Standard rails usually weigh between 30 kg/m and 60 kg/m. 3. Crane rails: Specifically designed to withstand heavy loads and intense impact forces caused by cranes and other heavy machinery. Crane rails are often used in industrial settings, ports, and shipyards. Their weight can range from 60 kg/m to over 100 kg/m. 4. Specialized rails: Apart from standard sizes, there are also specialized rails designed for specific purposes. For instance, grooved rails are used for tramways, while guard rails are installed in certain sections of the track to prevent derailment. It's important to consider factors such as the type of train, transportation load, speed requirements, and track conditions when selecting the appropriate rail size for a railway project. The appropriate rail size needed for a specific railway project depends on these factors.

- Q: Can steel rails be used in areas with seismic activity?

- Yes, steel rails can be used in areas with seismic activity. Steel is a strong and durable material that can withstand seismic forces. However, additional measures such as proper design, construction techniques, and maintenance should be implemented to ensure the safety and stability of the railway infrastructure in such areas.

- Q: Can steel rails be used in curved elevated railway structures?

- Curved elevated railway structures can indeed make use of steel rails. Due to its strength and durability, steel is a popular choice for railway construction. Its ability to withstand wear and tear, coupled with its versatility for shaping and bending, makes it an ideal material for accommodating curves in elevated railway structures. This, in turn, facilitates efficient and safe train operations. Furthermore, steel rails offer stability and support to the railway system, ensuring seamless train movement around curves. However, it is crucial to design and engineer the curved elevated railway structure correctly to guarantee that the steel rails can withstand the forces and stresses associated with the curvature.

- Q: Can steel rails be used for railway bridges?

- Yes, steel rails can be used for railway bridges. In fact, steel rails are commonly used in the construction of railway bridges due to their strength, durability, and ability to withstand heavy loads and vibrations.

- Q: How do steel rails handle sharp turns?

- Steel rails handle sharp turns by being designed with a combination of factors. The rails are bent in specific angles to accommodate the turn, and the track is banked or superelevated to counteract the centrifugal force. Additionally, the wheels of the train are tapered, allowing them to smoothly transition through the curve without derailing.

- Q: How are steel rails designed to accommodate different train speeds?

- Various factors are combined in the design of steel rails to accommodate different train speeds, ensuring optimal performance and safety. The anticipated maximum speed of the train is considered during the design process, taking into account factors such as the train's weight, size, acceleration, and deceleration rates. To support higher train speeds, steel rails are made stronger and more durable. This is achieved by using higher-grade steel and employing techniques that enhance its strength and resistance to wear and tear. The rails are manufactured with specific profiles and dimensions suitable for the expected train speeds, ensuring stability and minimizing the risk of derailment. Proper rail fastening systems are another important aspect of rail design for accommodating different train speeds. These systems secure the rails to the underlying support structure, such as sleepers or concrete ties, and help maintain alignment and stability. For higher speeds, more advanced and robust fastening systems are used to minimize vibrations, reduce the risk of track buckling, and ensure smoother train operations. Track geometry, including curves, gradients, and superelevation, is also considered in the design of steel rails for accommodating different train speeds. These elements are optimized to allow trains to negotiate turns and changes in elevation efficiently, even at higher speeds. Proper track alignment and smooth transitions between track sections are crucial to avoiding excessive lateral forces and ensuring passenger comfort and safety. In conclusion, the design of steel rails for accommodating different train speeds involves considering various factors such as anticipated speeds, train characteristics, rail strength, fastening systems, and track geometry. This comprehensive approach ensures that the rails can withstand the demands of higher speeds while providing a safe and comfortable ride for passengers and efficient transportation of goods.

- Q: How do steel rails contribute to reducing noise pollution in railways?

- Steel rails contribute to reducing noise pollution in railways in several ways. Firstly, steel is a dense and sturdy material that helps absorb and dampen vibrations caused by moving trains. This reduces the amount of noise generated during train operations. Additionally, steel rails are designed to have smooth surfaces, reducing the friction between the wheels and the rails. This results in less noise being produced as the trains move along the tracks. Overall, the use of steel rails in railways plays a significant role in minimizing noise pollution and creating a quieter environment for both passengers and nearby residents.

Send your message to us

High Quality Heavy Steel Rails for Rails of Tren GB38KG, GB43KG

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords