Grade AISI 304_304L Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade AISI 304_304L Stainless Steel Round Bar in stock

Descriptio of Grade AISI 304_304L Steel Round Bar in Stock

(stainless steel round bar, angle bar , flat bar , channel bar , hexagon bar , square bar .)

1.grade:201,202,301,302,303,304,304L,308,309,310,310S,316,316L,321,410,420,430,etc.

2.diameter:3mm-400mm.

3.surface:bright , black , pickeled & bright .

4.length: no more than 6 m .

5.packing: according to international standards of export .

6.trade terms: FOBshanghai , CIF+import port .

7.payment terms: L/C at sight , 30% T/T in advance + copy of B/L .

8.delivery time: within 8 to 12 days since the receipt of payment .

9. MOQ is 1 ton .

Description of Grade AISI 304_304L Steel Round Bar in Stock

Standard | AISI , JIS , ER , GB , ASTM , etc. |

| Grade | 201,201,301,302,303,304,304l,308,309,310,310S,316,316L,321,410,420,etc. |

| Application | widely used in the areas as ss fasteners , chains , kitchen and sanitary wares , furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc. with a high strength after cold-drawn , anti-stress corrosion , good surface . |

| Chemcial composition | according to international standards of ASTM , AISI , JIS , ER , GB ,etc. |

Company Information of Grade AISI 304_304L Steel Round Bar in Stock

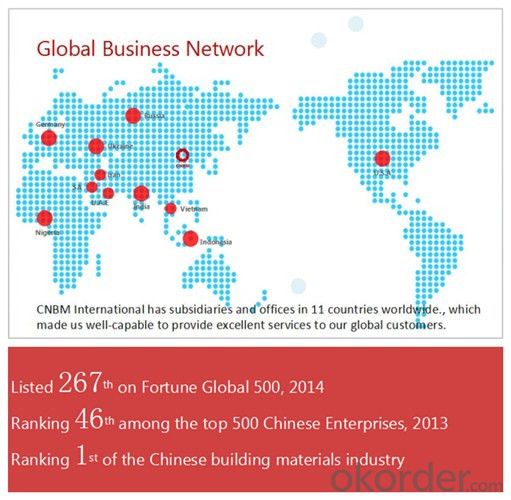

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Grade AISI 304_304L Steel Round Bar in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the non-destructive testing methods used for special steel?

- Some of the non-destructive testing methods used for special steel include ultrasonic testing, magnetic particle testing, liquid penetrant testing, and radiographic testing. These methods allow for the detection of defects, cracks, or other imperfections in the steel without causing any damage to the material itself.

- Q: How does special steel contribute to the medical aftermarket industry?

- The medical aftermarket industry heavily relies on special steel, which is essential for producing top-quality materials needed for medical devices and equipment. Special steel, also known as stainless steel, offers a wide range of advantages that make it perfect for medical applications. Above all, special steel's resistance to corrosion and rust is of utmost importance in the medical field, where hygiene and cleanliness are crucial. Medical devices like surgical instruments, implants, and equipment require frequent sterilization, and the corrosion resistance of special steel guarantees their durability and long-lasting nature. Moreover, special steel possesses exceptional strength and hardness properties, making it suitable for medical implants and prosthetics. These implants must be able to withstand the stresses and strains of the human body while maintaining their structural integrity. Special steel provides the necessary strength and toughness required for these critical applications. Furthermore, special steel is biocompatible, meaning it does not cause any negative reactions or toxicity when it comes into contact with living tissues. This characteristic is vital for implants and devices that directly interact with the human body, as it minimizes the risk of rejection or allergic reactions. Additionally, special steel's versatility allows for easy machining and fabrication into complex shapes and sizes, meeting the diverse requirements of medical applications. It can be shaped into delicate surgical instruments, precise cutting tools, and even large-scale equipment like hospital beds and imaging machines. The high precision and dimensional stability of special steel contribute to the accuracy and reliability of medical devices, especially in areas like diagnostics and imaging. Precise measurements and high-quality images are essential for accurate diagnosis and treatment planning, and special steel helps achieve these goals. In conclusion, special steel's corrosion resistance, strength, biocompatibility, and versatility make it an invaluable material in the medical aftermarket industry. Its use in manufacturing medical devices and equipment ensures the highest standards of hygiene, durability, and performance, ultimately contributing to the advancement of healthcare and improving patient outcomes.

- Q: What are the properties of corrosion-resistant stainless steel?

- Corrosion-resistant stainless steel has several key properties. Firstly, it has a high level of chromium content, typically around 10-20%, which forms a protective oxide layer on the surface of the steel. This oxide layer acts as a barrier, preventing oxygen and moisture from reaching the underlying metal and causing corrosion. Additionally, stainless steel contains other alloying elements such as nickel, molybdenum, and nitrogen, which further enhance its corrosion resistance. These alloys help to stabilize the oxide layer and make it more resistant to corrosion by aggressive substances such as acids, salts, and chlorides. Furthermore, stainless steel is highly durable and has excellent strength, making it suitable for various applications in corrosive environments, including marine, chemical, and food processing industries.

- Q: What are the different material selection factors for special steel?

- To ensure the desired performance, durability, and cost-effectiveness of the final product, engineers and designers must consider various factors when selecting materials for special steel. Key factors include mechanical properties, corrosion resistance, heat resistance, machinability, weldability, cost, availability, and environmental impact. 1. Mechanical Properties: Special steel must possess the necessary mechanical properties to meet the demands of the specific application. This includes strength, hardness, toughness, fatigue resistance, and wear resistance. 2. Corrosion Resistance: Depending on the intended use, special steel may need to have high corrosion resistance to withstand harsh environments, chemicals, or moisture. This ensures the longevity and reliability of the steel in its intended application. 3. Heat Resistance: Special steel may need to exhibit excellent heat resistance, especially for applications involving high temperatures like aerospace or power generation industries. The material should retain its strength and structural integrity even at elevated temperatures. 4. Machinability: The ease of machining special steel is crucial, especially for applications involving complex shapes or precision components. High machinability allows for efficient manufacturing processes and reduces production costs. 5. Weldability: Special steel selected for applications requiring welding should have good weldability. This ensures that the material can be easily welded without compromising strength or introducing defects. 6. Cost: The cost of the material plays a significant role in material selection. Engineers and designers must balance desired properties with the available budget to achieve optimal cost-effectiveness. 7. Availability: Ensuring a reliable and consistent supply of the chosen special steel is vital to avoid production delays or interruptions. 8. Environmental Impact: The environmental impact of the material should be evaluated, considering factors such as energy consumption during production, recyclability, and the use of sustainable raw materials. Opting for eco-friendly materials aligns with sustainable practices and regulations. By carefully considering these material selection factors, engineers and designers can choose the most suitable special steel for their specific application, ensuring optimal performance, durability, and cost-efficiency.

- Q: What are the main factors affecting the creep resistance of special steel?

- The creep resistance of special steel is determined by several factors, namely composition, microstructure, and processing conditions. The creep resistance is greatly affected by the composition of the steel. The presence of alloying elements like chromium, molybdenum, and vanadium can enhance creep resistance by forming stable precipitates or carbides that impede the movement of dislocations. These alloying elements also contribute to the formation of a protective oxide layer, which further improves resistance to creep. Microstructure is another crucial factor in determining creep resistance. Proper heat treatment or alloying can lead to the formation of fine-grained structures, which hinder dislocation movement and enhance material strength, thereby improving creep resistance. Grain boundaries also act as barriers to dislocation motion, reducing the rate of creep. Processing conditions, such as heat treatment and deformation processes, have a significant impact on creep resistance. The choice of heat treatment parameters, including temperature and cooling rate, can affect the precipitation of strengthening phases and the formation of an ideal microstructure. Appropriate deformation processing, such as hot or cold working, can refine the grain structure and enhance creep resistance. Temperature, stress, and time are additional factors that influence creep resistance. Higher temperatures accelerate creep deformation, while higher applied stresses increase the rate of creep. The duration of exposure to elevated temperatures and stresses also plays a role, as prolonged exposure can lead to creep failure. To summarize, the creep resistance of special steel is influenced by various factors, including composition, microstructure, processing conditions, temperature, stress, and time. By carefully considering and optimizing these factors, the creep resistance of special steel can be enhanced, making it suitable for applications that require high temperatures and long-term durability.

- Q: How does special steel contribute to reducing product waste?

- Special steel contributes to reducing product waste by offering superior strength, durability, and corrosion resistance. This allows manufacturers to produce longer-lasting and more reliable products, minimizing the need for frequent replacements. Additionally, special steel's high precision and customization capabilities enable the creation of components with tight tolerances, reducing the risk of assembly errors and subsequent product failures. Consequently, special steel helps optimize product performance and longevity, thereby reducing waste generated from premature product disposal.

- Q: How is special steel used in the marine supply chain?

- Special steel is used in the marine supply chain for various purposes. It is commonly used in the construction of ships and offshore structures due to its high strength and corrosion resistance properties. Special steel is also used in the manufacturing of marine equipment such as propellers, shafts, and valves, ensuring reliable performance and durability in harsh marine environments. Additionally, special steel plays a crucial role in the production of marine components, ensuring the safety and efficiency of the marine supply chain.

- Q: What are the different defense grades of special steel?

- Special steel is a category of steel that is specifically designed to possess enhanced properties, such as increased strength, durability, and resistance to various environmental factors. When it comes to defense applications, special steel is often utilized to manufacture armor and protective components for military vehicles, aircraft, and naval vessels. These defense grades of special steel are classified based on their specific characteristics and performance levels. One of the most common defense grades of special steel is known as ballistic steel. Ballistic steel is engineered to provide exceptional resistance against ballistic threats, including bullets and shrapnel. It possesses high tensile strength and hardness, which allows it to withstand the impact and penetration of projectiles. Ballistic steel is categorized into several grades, such as MIL-A-46100, MIL-A-12560, and AR500, each offering different levels of protection against various types of ammunition. Another defense grade of special steel is known as blast-resistant steel. This type of steel is designed to withstand explosions and minimize the damage caused by shockwaves, fragmentation, and heat. It is commonly used in the construction of blast-resistant walls, doors, and windows for military bases, embassies, and critical infrastructure facilities. Blast-resistant steel grades are classified based on their ability to withstand different levels of explosive forces, with higher grades providing greater protection. Additionally, there are specialized grades of special steel used for anti-vehicle applications. These grades, such as Armox and Ramor, are engineered to resist the impact of heavy-caliber projectiles and explosive devices, making them suitable for manufacturing armored vehicles and personnel carriers. They provide a combination of high hardness, toughness, and energy absorption properties, ensuring the safety of military personnel on the battlefield. Overall, the defense grades of special steel are diverse and tailored to meet the specific requirements of different defense applications. They provide essential protection and ensure the safety of military personnel and equipment in challenging and hostile environments. The choice of the appropriate grade depends on the nature of the threat, the level of protection needed, and the specific design and performance criteria of the defense application.

- Q: How does mold steel resist wear and erosion?

- Mold steel resists wear and erosion due to its high hardness and toughness properties. The steel is specifically designed to withstand the repetitive stress, abrasion, and impact that molds are subjected to during their operational lifespan. Additionally, mold steel is often treated with heat treatments or coatings to further enhance its resistance to wear and erosion, ensuring its durability and longevity in molding applications.

- Q: How is special steel used in the production of aircraft components?

- Special steel is used in the production of aircraft components due to its superior strength, durability, and resistance to corrosion. It is commonly used in critical parts such as engine components, landing gear, and structural elements. The unique properties of special steel ensure that aircraft components can withstand high temperatures, extreme pressures, and demanding operating conditions, ensuring the safety and reliability of aircraft.

Send your message to us

Grade AISI 304_304L Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords