Grade AISI309_309S Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade AISI 309_309S Stainless Steel Round Bar in stock

Descriptio of Grade AISI 309_309S Steel Round Bar in Stock

(stainless steel round bar, angle bar , flat bar , channel bar , hexagon bar , square bar .)

1.grade:201,202,301,302,303,304,304L,308,309,310,310S,316,316L,321,410,420,430,etc.

2.diameter:3mm-400mm.

3.surface:bright , black , pickeled & bright .

4.length: no more than 6 m .

5.packing: according to international standards of export .

6.trade terms: FOBshanghai , CIF+import port .

7.payment terms: L/C at sight , 30% T/T in advance + copy of B/L .

8.delivery time: within 8 to 12 days since the receipt of payment .

9. MOQ is 1 ton .

Description of Grade AISI309_309S Steel Round Bar in Stock

Standard | AISI , JIS , ER , GB , ASTM , etc. |

| Grade | 201,201,301,302,303,304,304l,308,309,310,310S,316,316L,321,410,420,etc. |

| Application | widely used in the areas as ss fasteners , chains , kitchen and sanitary wares , furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc. with a high strength after cold-drawn , anti-stress corrosion , good surface . |

| Chemcial composition | according to international standards of ASTM , AISI , JIS , ER , GB ,etc. |

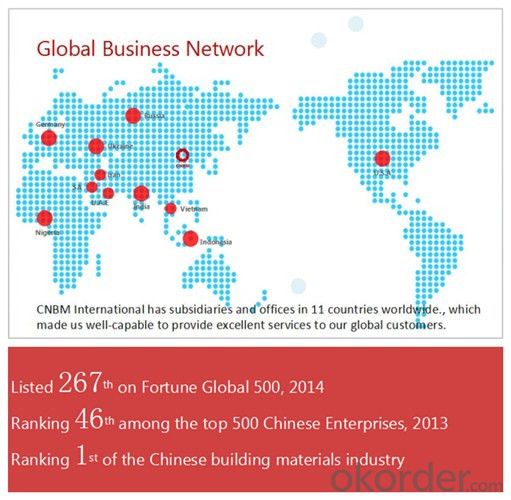

Company Information of Grade AISI309_309S Steel Round Bar in Stock

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Grade AISI309_309S Steel Round Bar in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: How is special steel used in the defense manufacturing process?

- Special steel is used in the defense manufacturing process to create weapons, vehicles, and equipment that require high strength, durability, and resistance to extreme conditions. It is used to manufacture components such as armor plates, gun barrels, missile casings, and aircraft parts, ensuring the integrity and effectiveness of defense systems. Furthermore, special steel's unique properties, such as hardness, toughness, and corrosion resistance, make it an essential material for enhancing the performance and protection capabilities of military equipment.

- Q: What are the common quality control measures for special steel?

- Common quality control measures for special steel include: 1. Chemical Composition Analysis: Special steel often requires specific chemical compositions to meet the desired properties. Quality control measures involve analyzing the chemical composition through techniques like spectrometry to ensure it meets the required specifications. 2. Mechanical Testing: Special steel needs to possess specific mechanical properties such as strength, hardness, toughness, and ductility. Quality control measures involve conducting mechanical tests like tensile testing, hardness testing, impact testing, and fatigue testing to ensure the steel meets the required standards. 3. Non-Destructive Testing: Non-destructive testing methods like ultrasonic testing, magnetic particle testing, and dye penetrant testing are employed to detect any internal or surface defects in the steel. These tests help ensure the integrity and reliability of the special steel. 4. Dimensional Inspection: Special steel often requires precise dimensions for its intended application. Dimensional inspection involves measuring the length, width, thickness, diameter, and other critical dimensions to ensure they meet the required tolerances specified by the customer or industry standards. 5. Surface Quality Inspection: Special steel may require specific surface finishes or coatings to enhance its performance or resistance to corrosion. Quality control measures involve inspecting the steel surface for defects such as cracks, pits, scratches, or unevenness to ensure it meets the required surface quality standards. 6. Heat Treatment Verification: Special steel often undergoes heat treatment processes like annealing, quenching, or tempering to achieve the desired mechanical properties. Quality control measures involve verifying the effectiveness of the heat treatment process through hardness testing or microstructure analysis. 7. Documentation and Traceability: Quality control measures also involve maintaining comprehensive documentation and traceability records of the special steel, including details of its production process, chemical composition, mechanical properties, and any inspections or tests performed. This helps ensure quality consistency and provides a reference for future use or troubleshooting. By implementing these quality control measures, manufacturers can ensure that special steel meets the required specifications, providing customers with high-quality and reliable products for their specific applications.

- Q: What are the different forging methods used for special steel?

- Special steel can be forged using several different methods, including open die forging, closed die forging, and ring rolling. Open die forging, also known as smith forging, involves heating the metal and shaping it between flat dies or anvils. The metal is hammered and rotated repeatedly until it reaches the desired shape. This method is ideal for producing customized large and complex shapes. Closed die forging, also known as impression die forging, requires placing the heated metal between multiple dies that have impressions of the final shape. The metal is compressed to fill the impressions and take on the shape of the dies. This method is suitable for producing accurately sized small to medium components. Ring rolling is a specific forging method used to create seamless rings. The metal is heated and positioned between two rollers, which apply pressure to shape the metal into a ring. This technique is commonly used for producing rings with thin walls and large diameters. Secondary forging processes can be employed to further enhance the properties of special steel. Heat treatment, such as annealing or quenching, can improve the material's strength and hardness. Additionally, machining operations can be performed to achieve the desired dimensions and surface finish. The choice of forging method for special steel depends on factors such as the desired shape, size, and properties of the final product. Each method has its own advantages and limitations, and manufacturers select the most appropriate technique based on the specific requirements of the application.

- Q: What are the different automotive grades of special steel?

- There are several different automotive grades of special steel used in the automotive industry. These grades are specifically designed to meet the unique requirements and demands of the automotive sector. Some of the commonly used grades include: 1. Advanced High-Strength Steels (AHSS): These grades of steel are known for their exceptional strength and excellent formability. AHSS is used in critical automotive components like chassis, body panels, and safety systems to enhance crash performance while reducing weight. 2. Dual-Phase Steels (DP): DP steels are a type of AHSS that offer a combination of high strength and good ductility. They are commonly used in automotive applications that require both strength and formability, such as structural components and reinforcements. 3. Martensitic Steels: These steels are known for their high strength and hardness. They are often used in automotive applications that require resistance to wear and impact, such as crankshafts, gears, and axles. 4. Transformation-Induced Plasticity (TRIP) Steels: TRIP steels are designed to provide high strength, good formability, and excellent energy absorption during impact. They are utilized in automotive safety components like bumper reinforcements and crash boxes. 5. High-Strength Low-Alloy (HSLA) Steels: HSLA steels offer a balance between strength, formability, and cost-effectiveness. They are commonly used in automotive structural components and suspension systems to reduce weight while maintaining structural integrity. 6. Stainless Steels: Stainless steels are corrosion-resistant and are used in automotive applications that require resistance to rust and corrosion, such as exhaust systems, fuel tanks, and decorative trims. These different grades of special steel provide automotive manufacturers with a wide range of options to meet specific needs in terms of strength, formability, durability, and corrosion resistance. The selection of the appropriate grade depends on the intended application and the desired performance characteristics.

- Q: What are the properties of maraging steel?

- Maraging steel is a type of high-strength steel known for its exceptional strength, toughness, and resistance to fatigue. It possesses a unique combination of properties such as high yield strength, excellent fracture toughness, and superior hardness. This steel also exhibits remarkable corrosion resistance and can withstand extreme temperatures. Additionally, maraging steel is highly weldable and machinable, making it suitable for a wide range of applications in industries such as aerospace, defense, and tooling.

- Q: How does special steel perform in abrasive wear applications?

- Special steel is renowned for its outstanding performance in applications where abrasive wear is present. Its design specifically caters to endure the harsh conditions and high levels of abrasion that occur in diverse industrial processes. A notable characteristic of special steel is its remarkable hardness. It can effectively withstand the abrasive forces exerted by different materials, such as rocks, sand, or minerals, without experiencing significant wear or deterioration. Achieving this hardness involves a combination of alloying elements and heat treatment processes, which enhance the steel's ability to maintain its structural integrity even under extreme wear conditions. Furthermore, special steel often possesses a high level of toughness, allowing it to absorb impact and resist fracture or chipping. This property is particularly crucial in applications involving abrasive wear, where materials frequently collide and generate high levels of stress. The toughness of special steel enables it to withstand these impacts and sustain its performance over an extended period. Moreover, special steel exhibits excellent corrosion resistance, which is vital in abrasive wear applications that involve exposure to moisture, chemicals, or other corrosive agents. This resistance guarantees that the steel does not deteriorate or lose its effectiveness due to chemical reactions or oxidation, extending its lifespan and reducing the need for maintenance. To summarize, special steel excels in abrasive wear applications due to its hardness, toughness, and corrosion resistance. These properties enable it to endure the challenging conditions and high levels of abrasion encountered in various industrial processes, ensuring long-lasting performance and minimizing downtime.

- Q: What are the quality control measures for special steel?

- The quality control measures for special steel typically include thorough inspection and testing of raw materials, monitoring and controlling the manufacturing process, conducting various mechanical and chemical tests, ensuring dimensional accuracy and surface finish, and conducting final inspection and certification to meet specific industry standards. These measures are essential to ensure the desired properties and performance of special steel, as well as to meet customer requirements and ensure product reliability and safety.

- Q: How does sulfur affect the machinability of special steel?

- Sulfur can have both positive and negative effects on the machinability of special steel. On one hand, sulfur acts as a free-machining element when added in small amounts. It forms sulfide inclusions that help improve the chip-breaking ability during machining, resulting in better surface finish, reduced tool wear, and improved cutting speeds. This is particularly beneficial for high-speed machining operations. On the other hand, excessive sulfur content can have detrimental effects on machinability. High levels of sulfur can lead to the formation of brittle sulfide inclusions, causing poor machinability and reduced mechanical properties. It can result in increased tool wear, poor surface finish, and lower cutting speeds. Additionally, sulfur can promote the formation of built-up edge, which further hampers the machinability of special steel. Therefore, it is crucial to maintain an optimal sulfur content in special steel to strike a balance between improved machinability and maintaining the desired mechanical properties. Proper control of sulfur levels in the steel composition, along with appropriate machining techniques and tool selection, is necessary to achieve efficient and high-quality machining of special steel.

- Q: How does special steel contribute to the automotive racing machinery industry?

- The automotive racing machinery industry greatly relies on special steel to enhance the performance, durability, and safety of racing vehicles. One significant benefit of special steel is its ability to boost the power and speed of racing cars. Steel alloys like carbon fiber-reinforced steel or high-strength steel offer exceptional strength-to-weight ratios, enabling manufacturers to reduce vehicle weight without compromising structural integrity. This weight reduction enhances acceleration and maneuverability, resulting in increased speed and improved lap times on the track. Apart from performance improvements, special steel also makes racing vehicles safer. Certain steel alloys possess high strength and impact resistance, making them ideal for constructing roll cages, chassis, and other critical safety components. These materials can withstand extreme forces during crashes or collisions, providing enhanced protection for drivers and minimizing the risk of severe injuries. Special steel also contributes to the longevity and durability of automotive racing machinery. The demanding conditions of racing, including high temperatures, vibrations, and mechanical stress, can quickly deform or deteriorate regular steel. However, special steel alloys are specifically engineered to withstand these harsh environments, ensuring racing cars can withstand the sport's rigorous demands without compromising performance or safety. Furthermore, special steel alloys offer excellent thermal conductivity and heat resistance, which are essential for racing vehicles that generate substantial heat during high-speed runs. By efficiently dissipating heat, special steel helps prevent overheating and ensures optimal engine performance, minimizing the risk of mechanical failures and maximizing the lifespan of racing machinery. In summary, special steel significantly contributes to the automotive racing machinery industry by enhancing the performance, durability, and safety of racing vehicles. The use of high-performance steel alloys increases speed, improves lap times, and reduces vehicle weight. Additionally, it provides superior strength and impact resistance, enhancing safety during crashes or collisions. Moreover, special steel alloys offer excellent heat resistance and thermal conductivity, ensuring optimal engine performance and prolonging the lifespan of racing machinery.

- Q: Is special steel suitable for manufacturing firearms?

- Yes, special steel is suitable for manufacturing firearms. Special steel, also known as alloy steel, offers excellent strength, durability, and resistance to wear and tear, making it an ideal material for firearm production. It provides the necessary mechanical properties required for firearm components, ensuring reliable performance and long-lasting functionality. Additionally, special steel can be heat-treated to enhance its hardness and toughness, further enhancing its suitability for manufacturing firearms.

Send your message to us

Grade AISI309_309S Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords