3 Aluminum Round Stock

3 Aluminum Round Stock Related Searches

Aluminum Round Stock 3 3 Inch Aluminum Round Stock 5 Aluminum Round Stock 4 Aluminum Round Stock 3 8 Aluminum Round Stock 2 Aluminum Round Stock 6 Aluminum Round Stock 3/8 Aluminum Round Stock 1 2 Aluminum Round Stock 1 Aluminum Round Stock 3 Aluminum Angle Stock 1 4 Aluminum Round Stock 3/4 Aluminum Round Stock 1 1 2 Aluminum Round Stock 1 1 4 Aluminum Round Stock 3 Aluminum Bar Stock Aluminum Bar Stock Round Round Stock Aluminum 1 Inch Aluminum Round Stock Aluminum Round Stock For Sale 3 4 Aluminum Square Stock Aluminum Round Stock Prices Solid Aluminum Round Stock 4 Inch Aluminum Round Stock 2 Inch Aluminum Round Stock Aluminum Round Stock Sizes Casting Aluminum Round Stock Round Aluminum Stock Aluminum Round Stock Near Me 1.5 Aluminum Round Stock3 Aluminum Round Stock Supplier & Manufacturer from China

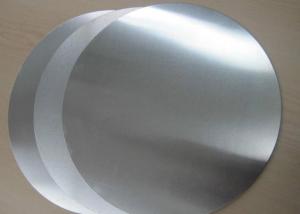

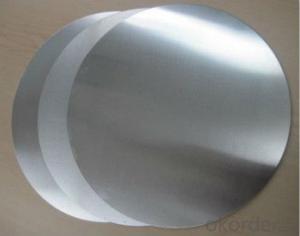

3 Aluminum Round Stock is a versatile material known for its lightweight properties, corrosion resistance, and high strength-to-weight ratio. This product comes in various diameters and lengths, making it suitable for a wide range of applications. It is commonly used in industries such as aerospace, automotive, and construction, where its durability and workability are highly valued.The 3 Aluminum Round Stock is widely utilized in manufacturing processes, including machining, bending, and extrusion, due to its excellent malleability and ease of fabrication. It is ideal for creating various components, such as brackets, frames, and structural supports, that require a combination of strength and lightness. Its non-magnetic and non-sparking characteristics also make it a preferred choice for applications in environments where safety is a priority.

Okorder.com is a leading wholesale supplier of 3 Aluminum Round Stock, boasting a substantial inventory that caters to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the 3 Aluminum Round Stock they provide meets the highest industry standards. Their extensive range of products allows customers to find the exact specifications they require, making Okorder.com a one-stop-shop for all 3 Aluminum Round Stock needs.

Hot Products