Grade AISI304L_316L Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade AISI 304L_316L Stainless Steel Round Bar in stock

Descriptio of Grade AISI 304L_316L Steel Round Bar in Stock

(stainless steel round bar, angle bar , flat bar , channel bar , hexagon bar , square bar .)

1.grade:201,202,301,302,303,304,304L,308,309,310,310S,316,316L,321,410,420,430,etc.

2.diameter:3mm-400mm.

3.surface:bright , black , pickeled & bright .

4.length: no more than 6 m .

5.packing: according to international standards of export .

6.trade terms: FOBshanghai , CIF+import port .

7.payment terms: L/C at sight , 30% T/T in advance + copy of B/L .

8.delivery time: within 8 to 12 days since the receipt of payment .

9. MOQ is 1 ton .

Description of Grade AISI 304L_316L Steel Round Bar in Stock

Standard | AISI , JIS , ER , GB , ASTM , etc. |

| Grade | 201,201,301,302,303,304,304l,308,309,310,310S,316,316L,321,410,420,etc. |

| Application | widely used in the areas as ss fasteners , chains , kitchen and sanitary wares , furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc. with a high strength after cold-drawn , anti-stress corrosion , good surface . |

| Chemcial composition | according to international standards of ASTM , AISI , JIS , ER , GB ,etc. |

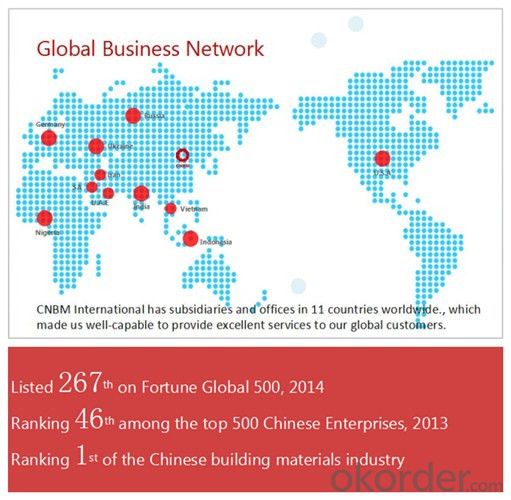

Company Information of Grade AISI 304L_316L Steel Round Bar in Stock

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Grade AISI 304L_316L Steel Round Bar in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: Can special steel be used in the semiconductor industry?

- Yes, special steel can be used in the semiconductor industry. Special steel alloys, such as stainless steel or high-temperature alloys, are often utilized for various components and equipment used in semiconductor manufacturing processes. These steels offer excellent corrosion resistance, high strength, and resistance to high temperatures, making them suitable for critical applications in the semiconductor industry.

- Q: How does special steel perform in high-temperature fatigue?

- Special steel performs well in high-temperature fatigue due to its enhanced mechanical properties and resistance to thermal degradation. It exhibits excellent strength, toughness, and creep resistance, allowing it to withstand prolonged exposure to elevated temperatures without significant loss in performance. Additionally, special steel is designed to maintain its structural integrity and resist fatigue failure even under repeated cyclic loading, making it a reliable choice for high-temperature applications.

- Q: What are the main advantages of using special steel in the automotive industry?

- Special steel has several main advantages in the automotive industry. Firstly, it offers increased strength and durability, allowing for lighter weight components without compromising safety. This not only improves fuel efficiency but also enhances overall vehicle performance. Secondly, special steel has excellent corrosion resistance, ensuring a longer lifespan and reducing maintenance costs. Lastly, its versatility enables the production of complex shapes and designs, enabling manufacturers to create innovative and efficient automotive structures.

- Q: What are the machining techniques for special steel?

- Some of the machining techniques for special steel include turning, milling, drilling, grinding, and broaching. These techniques are used to shape and form the steel into the desired dimensions and features, while also ensuring a smooth surface finish. Additionally, special steel may require specific cooling and lubrication methods during machining to minimize heat damage and maximize tool life.

- Q: Can special steel be used in automotive engine components?

- Yes, special steel can be used in automotive engine components. Special steel, such as high-strength, heat-resistant, or corrosion-resistant alloys, is often selected for critical engine parts like crankshafts, connecting rods, valves, and camshafts to enhance performance, durability, and efficiency.

- Q: What are the common defects found in special steel?

- Common defects found in special steel can vary depending on the specific type and manufacturing process used. However, there are a few defects that tend to be more common across different types of special steel. One common defect is surface imperfections, such as cracks, pits, or scratches. These defects can occur during the manufacturing process or can be a result of handling and transportation. Surface imperfections can affect the appearance of the steel and may also compromise its structural integrity. Another common defect is internal voids or inclusions. These are small pockets of gas or non-metallic materials trapped within the steel during the casting or forging process. Internal voids can weaken the steel and make it more prone to failure under stress. Inconsistent composition is another defect that can occur in special steel. This can happen when the alloying elements are not uniformly distributed throughout the steel. Inconsistent composition can lead to variations in mechanical properties and can make the steel less reliable and predictable in its performance. Grain structure defects are also common in special steel. These defects occur when the grains within the steel are improperly formed or are not uniform in size. Grain structure defects can affect the strength and toughness of the steel, making it more susceptible to fracture or deformation. Lastly, improper heat treatment can also result in defects in special steel. Heat treatment is a critical process in steel manufacturing, and if not done correctly, it can lead to various defects, such as excessive hardness, brittleness, or poor dimensional stability. It is important to note that while these defects are common, they can be minimized or eliminated through careful manufacturing processes, quality control measures, and proper handling and storage of the steel.

- Q: Is special steel suitable for manufacturing molds and dies?

- Yes, special steel is highly suitable for manufacturing molds and dies. Special steel refers to a group of high-quality steels that possess exceptional properties such as high hardness, wear resistance, toughness, and excellent heat resistance. These characteristics make special steel an ideal choice for mold and die manufacturing. Molds and dies are critical components in various industries such as automotive, aerospace, electronics, and manufacturing. They are used to shape, form, and cut materials into desired shapes and sizes. Due to the repetitive and intense nature of their applications, molds and dies are subjected to high pressures, temperatures, and abrasive forces. Therefore, they need to be made from a material that can withstand these conditions while maintaining their dimensional stability and performance. Special steel, such as tool steel, is specifically designed to meet these requirements. It has a high hardness level, which enables it to resist wear and deformation, even under extreme conditions. This characteristic ensures that molds and dies made from special steel can maintain their shape and precision for a longer period, resulting in better product quality and reduced downtime for maintenance and replacement. Additionally, special steel offers excellent heat resistance, which is crucial for molds and dies used in high-temperature applications such as plastic injection molding or forging. It can withstand the thermal cycling and rapid heating and cooling associated with these processes without losing its mechanical properties or developing cracks or deformation. Moreover, special steel is known for its exceptional toughness, which is essential for molds and dies that are subjected to high pressures and impacts. It can absorb and distribute the applied forces, preventing premature failure and prolonging the lifespan of the molds and dies. In summary, special steel is highly suitable for manufacturing molds and dies due to its high hardness, wear resistance, toughness, and excellent heat resistance. Its exceptional properties ensure that molds and dies can withstand the demanding conditions of their applications, resulting in improved performance, longevity, and cost-effectiveness for manufacturers.

- Q: How does special steel perform in high-temperature fatigue resistance?

- Special steel performs well in high-temperature fatigue resistance due to its unique composition and heat treatment processes. It has enhanced mechanical properties, such as high strength and toughness, which enable it to withstand repeated cyclic loading and resist deformation, even at elevated temperatures. Additionally, special steel exhibits excellent thermal stability, preventing the degradation of its microstructure and maintaining its mechanical properties over time. Overall, special steel is a reliable material choice for applications requiring high-temperature fatigue resistance.

- Q: Can special steel be used in the solar panel manufacturing industry?

- Yes, special steel can be used in the solar panel manufacturing industry. Special steel, such as stainless steel or high-strength steel, is often utilized in the construction of solar panel frames, mounting structures, and other supporting components due to its durability, corrosion resistance, and mechanical properties.

- Q: What are the applications of special steel in the medical field?

- The medical field benefits greatly from the unique properties and characteristics of special steel, which has a wide range of applications. Surgical instruments are one major area where special steel, such as stainless steel, is extensively used. These instruments, including scalpels, forceps, scissors, and surgical needles, require strength, durability, and resistance to corrosion. Special steel provides the necessary qualities to ensure these instruments maintain their sharpness and integrity even after repeated use and sterilization. Another important application of special steel in healthcare is the production of implants and prosthetics. Various special steel alloys, such as titanium alloys, cobalt-chromium alloys, and nickel-titanium alloys, are commonly employed to manufacture orthopedic and dental implants, as well as other medical devices. These alloys possess excellent biocompatibility, corrosion resistance, and mechanical strength, which make them ideal for long-term implantation within the human body. Special steel also plays a crucial role in the construction of medical equipment and machinery. Diagnostic machines like MRI scanners and X-ray machines often incorporate special steel components due to their magnetic properties and ability to withstand high temperatures. By utilizing special steel, the accuracy, reliability, and safety of these devices are ensured. Furthermore, special steel is used in the manufacturing of medical storage and transportation systems. Steel cabinets, trolleys, and containers are commonly used to store and transport medical supplies, instruments, and samples. The use of special steel in these systems guarantees durability, hygiene, and a long lifespan. Special steel is easy to clean, resistant to contamination, and maintains its quality over time. In conclusion, special steel is extensively utilized in the medical field for a variety of purposes. From surgical instruments to implants, medical equipment to storage systems, special steel is an essential material that contributes to the effectiveness, reliability, and safety of medical procedures and treatments. Its unique properties make it an indispensable resource in the healthcare industry.

Send your message to us

Grade AISI304L_316L Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords