Grade AISI431 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade AISI431 Stainless Steel Round Bar in stock

Descriptio of Grade AISI431 Steel Round Bar in Stock

(stainless steel round bar, angle bar , flat bar , channel bar , hexagon bar , square bar .)

1.grade:201,202,301,302,303,304,304L,308,309,310,310S,316,316L,321,410,420,430,etc.

2.diameter:3mm-400mm.

3.surface:bright , black , pickeled & bright .

4.length: no more than 6 m .

5.packing: according to international standards of export .

6.trade terms: FOBshanghai , CIF+import port .

7.payment terms: L/C at sight , 30% T/T in advance + copy of B/L .

8.delivery time: within 8 to 12 days since the receipt of payment .

9. MOQ is 1 ton .

Description of Grade AISI431Steel Round Bar in Stock

Standard | AISI , JIS , ER , GB , ASTM , etc. |

| Grade | 201,201,301,302,303,304,304l,308,309,310,310S,316,316L,321,410,420,etc. |

| Application | widely used in the areas as ss fasteners , chains , kitchen and sanitary wares , furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc. with a high strength after cold-drawn , anti-stress corrosion , good surface . |

| Chemcial composition | according to international standards of ASTM , AISI , JIS , ER , GB ,etc. |

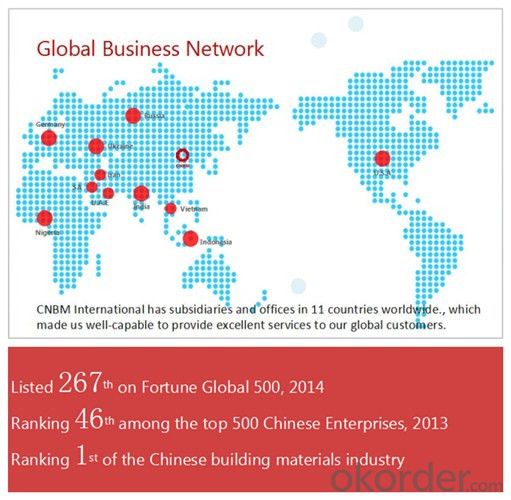

Company Information of Grade AISI431 Steel Round Bar in Stock

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Grade AISI431 Steel Round Bar in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What grade of iron powder should be used for processing special steel? Are there any other elements on the request? How much are they?

- The main special steel carbon structural steel, carbon tool steel, carbon spring steel, alloy spring steel, alloy structural steel, bearing steel, alloy tool steel, alloy tool steel, high-speed tool steel, stainless steel, heat-resistant steel and high-temperature alloy, precision alloy, gold and other electric heating.

- Q: What are the different methods of preventing pitting corrosion in special steel?

- There are several methods available to prevent pitting corrosion in special steel. These techniques aim to protect the steel surface from the corrosive environment and inhibit the formation of pits. Some of the commonly used methods include: 1. Passivation: Passivation involves treating the steel surface with a chemical solution or coating to create a protective oxide layer. This layer acts as a barrier, preventing the penetration of corrosive agents and reducing the risk of pitting corrosion. 2. Alloying: By adding specific alloying elements to the steel composition, its resistance to corrosion can be improved. Elements such as chromium, nickel, and molybdenum are often used as they enhance the steel's ability to form a stable passive film and resist pitting corrosion. 3. Cathodic protection: This method involves using a sacrificial anode or applying an impressed current to the steel surface. By making the steel cathodic, it becomes less susceptible to corrosion as electrons are drawn away from it, preventing the formation of pits. 4. Coatings: Applying a protective coating to the steel surface can effectively prevent pitting corrosion. Coatings such as paint, epoxy, or polymer-based materials act as a physical barrier, shielding the steel from corrosive agents. 5. Environmental control: Controlling the environment surrounding the steel can also help prevent pitting corrosion. This includes measures such as regulating temperature, humidity, and pH levels to ensure they are within acceptable limits and inhibiting the corrosion process. 6. Regular maintenance: Regular inspection and maintenance of the steel surface are crucial for preventing pitting corrosion. Any signs of damage or deterioration should be addressed promptly to prevent further corrosion and potential pitting. It is important to note that the choice of prevention method depends on various factors such as the specific steel composition, the corrosive environment, and the intended application. Proper selection and implementation of these methods can significantly enhance the resistance of special steel to pitting corrosion, ensuring its longevity and performance.

- Q: What are the different methods of surface lapping for special steel?

- There are several methods of surface lapping for special steel, including abrasive lapping, diamond lapping, and chemical lapping. Abrasive lapping involves using an abrasive material, such as silicon carbide or aluminum oxide, to remove small amounts of material from the surface of the steel. Diamond lapping, on the other hand, utilizes diamond particles to achieve a high level of precision and smoothness. Chemical lapping involves using a chemical compound that reacts with the steel surface, selectively removing material to achieve the desired finish. Each method has its own advantages and is chosen based on the specific requirements of the steel and the desired outcome.

- Q: How does special steel perform in electrical conductivity applications?

- Special steel, also known as stainless steel, offers excellent electrical conductivity properties in various applications. It is widely used in electrical engineering and electronics due to its high corrosion resistance and low electrical resistance. The addition of specific alloys such as chromium and nickel enhances its conductivity, making it an ideal choice for conducting electricity efficiently. In electrical conductivity applications, special steel exhibits low resistivity, allowing for the smooth flow of electrical current without significant loss of energy. Its low resistance minimizes the generation of heat, which is crucial for preventing overheating and ensuring the efficient operation of electrical components. Special steel also possesses excellent magnetic properties, making it suitable for applications that require both electrical conductivity and magnetic strength. This property is particularly useful in the production of transformers, motors, and generators. Moreover, special steel is highly durable and can withstand harsh environmental conditions, making it suitable for outdoor applications. Its corrosion resistance prevents the formation of rust, ensuring a long lifespan and consistent performance even in challenging environments. In summary, special steel is an excellent choice for electrical conductivity applications due to its low electrical resistance, high corrosion resistance, and exceptional durability. Its unique properties make it a preferred material in various industries that rely on efficient and reliable electrical conductivity.

- Q: Is special steel resistant to chemical corrosion?

- Yes, special steel is generally resistant to chemical corrosion due to its high levels of alloying elements such as chromium, nickel, and molybdenum. These elements form a protective layer on the steel surface that helps prevent the penetration of corrosive substances, making it highly resistant to chemical corrosion.

- Q: What are the applications of special steel in the automotive manufacturing process?

- Special steel has several applications in the automotive manufacturing process. It is commonly used in the production of engine components, such as crankshafts, camshafts, and connecting rods, due to its high strength and resistance to wear and tear. Special steel is also utilized in the manufacturing of suspension components, such as springs and shock absorbers, as it provides the necessary durability and resilience to withstand the constant stresses and strains of the vehicle's operation. Additionally, special steel is employed in the production of safety features, including seat belt pretensioners and airbag components, as it offers the required toughness and impact resistance. Overall, special steel plays a vital role in enhancing the performance, safety, and longevity of automotive vehicles.

- Q: What are the different renewable energy grades of special steel?

- There are different grades of special steel used in the production of renewable energy equipment, such as wind turbines, solar panels, and hydroelectric generators. These grades include high-strength steel, corrosion-resistant steel, and heat-resistant steel. Each grade is specifically designed to withstand the unique operating conditions and environmental factors associated with renewable energy applications.

- Q: How does special steel contribute to the electrical conductivity of products?

- Several methods can be employed to utilize special steel in enhancing the electrical conductivity of products. Firstly, the formulation of special steel alloys can be tailored with specific chemical compositions that enhance its electrical conductivity. For instance, the addition of elements like copper, silver, or nickel to the steel creates additional pathways for the flow of electric current, thus increasing the conductivity. Moreover, manipulating the microstructure of special steel can also contribute to improved electrical conductivity. By controlling the size and orientation of the steel's grains, the resistance to the flow of electrons can be reduced, consequently enhancing the overall conductivity of the material. Furthermore, subjecting special steel to heat treatment or other processes can further enhance its electrical conductivity. Techniques such as annealing or tempering can effectively eliminate impurities and enhance the crystal structure of the steel, resulting in improved conductivity. In addition to these methods, special steel can also be designed with low magnetic permeability, reducing its resistance to the flow of magnetic fields. This characteristic proves advantageous in applications where minimizing electromagnetic interference is crucial, such as in electrical connectors or transformers. To summarize, special steel contributes to the electrical conductivity of products through various means, including its chemical composition, microstructural control, heat treatment, and low magnetic permeability. By optimizing these factors, special steel can significantly enhance the performance of electrical components and systems.

- Q: How does special steel contribute to the automotive suspension industry?

- Special steel contributes to the automotive suspension industry by providing high strength and durability to suspension components. It allows for lighter and more efficient designs, improving handling, stability, and overall performance of vehicles. Special steel also enhances safety by increasing the ability to absorb and dampen shocks and vibrations, resulting in a smoother and more comfortable ride for passengers.

- Q: How does nitriding steel improve hardness and wear resistance?

- Nitriding steel improves hardness and wear resistance by introducing nitrogen into the steel's surface through a heat treatment process. This forms nitrides, which are hard compounds that increase the material's surface hardness. Additionally, the nitrogen atoms create compressive stresses within the structure, enhancing the material's resistance to wear and fatigue.

Send your message to us

Grade AISI431 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords