Grade AISI 304_316_321 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade AISI 304_316_321 Stainless Steel Round Bar in stock

Descriptio of Grade AISI 304_316_321 Steel Round Bar in Stock

(stainless steel round bar, angle bar , flat bar , channel bar , hexagon bar , square bar .)

1.grade:201,202,301,302,303,304,304L,308,309,310,310S,316,316L,321,410,420,430,etc.

2.diameter:3mm-400mm.

3.surface:bright , black , pickeled & bright .

4.length: no more than 6 m .

5.packing: according to international standards of export .

6.trade terms: FOBshanghai , CIF+import port .

7.payment terms: L/C at sight , 30% T/T in advance + copy of B/L .

8.delivery time: within 8 to 12 days since the receipt of payment .

9. MOQ is 1 ton .

Description of Grade AISI 304_316_321 Steel Round Bar in Stock

Standard | AISI , JIS , ER , GB , ASTM , etc. |

| Grade | 201,201,301,302,303,304,304l,308,309,310,310S,316,316L,321,410,420,etc. |

| Application | widely used in the areas as ss fasteners , chains , kitchen and sanitary wares , furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc. with a high strength after cold-drawn , anti-stress corrosion , good surface . |

| Chemcial composition | according to international standards of ASTM , AISI , JIS , ER , GB ,etc. |

Company Information of Grade AISI 304_316_321 Steel Round Bar in Stock

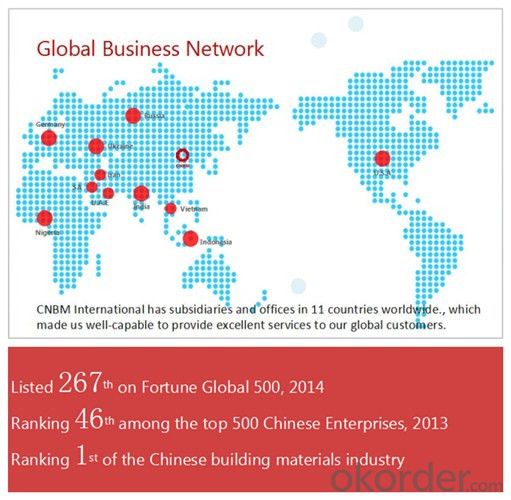

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Grade AISI 304_316_321 Steel Round Bar in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different heat treatment processes for special steel?

- Some of the different heat treatment processes for special steel include annealing, quenching and tempering, hardening, case hardening, and precipitation hardening.

- Q: What are the different testing methods used for special steel?

- Some of the different testing methods used for special steel include hardness testing, tensile testing, impact testing, metallographic examination, ultrasonic testing, and magnetic particle testing.

- Q: What are the challenges in forming special steel?

- One challenge in forming special steel is achieving the desired mechanical properties while maintaining the desired shape and dimensions. Special steels often require precise and complex processing techniques, including heat treatment, forging, and machining, which can be challenging to execute accurately. Additionally, special steels may have specific chemical compositions that make them more susceptible to cracking, warping, or distortion during the forming process, further adding to the challenges involved. Controlling these factors and ensuring the final product meets the required specifications requires a high level of expertise and careful attention to detail.

- Q: Carbon steel and stainless steel and pattern steel and special steel and high carbon steel difference

- Stainless steel with high chromium content and high grade steel is forged together with different steel

- Q: Can special steel be used in extreme weather conditions?

- Yes, special steel can be used in extreme weather conditions. Specialized steel alloys such as stainless steel or weathering steel are designed to withstand harsh environments, including extreme temperatures, high humidity, corrosive elements, and exposure to UV radiation. These steels offer enhanced durability, resistance to corrosion, and excellent structural integrity, making them suitable for various applications in extreme weather conditions.

- Q: What are the different heat treatment processes used in special steel?

- There are several heat treatment processes used in special steel, including annealing, normalizing, quenching, tempering, and precipitation hardening. Annealing involves heating the steel to a high temperature and then slowly cooling it, which helps to relieve internal stresses and improve its ductility. Normalizing is similar to annealing, but the cooling process is done in still air, resulting in a more uniform grain structure. Quenching involves rapidly cooling the steel in a liquid, such as water or oil, to achieve high hardness and strength. Tempering is a process that follows quenching, where the steel is reheated to a specific temperature and then cooled, which reduces the brittleness and improves toughness. Lastly, precipitation hardening involves heating the steel to a high temperature and then cooling it quickly to form fine precipitates that enhance its strength.

- Q: What are the different surface hardening techniques used for special steel?

- There are several surface hardening techniques used for special steel, including carburizing, nitriding, induction hardening, flame hardening, and laser hardening.

- Q: What are the emerging trends in special steel production?

- Some of the emerging trends in special steel production include the use of advanced technologies, such as additive manufacturing and automation, to enhance efficiency and precision in the production process. Additionally, there is a growing demand for eco-friendly and sustainable production methods, leading to the development of greener steelmaking processes. Furthermore, there is a focus on creating specialty steels with improved properties, such as higher strength, corrosion resistance, and heat resistance, to meet the evolving needs of various industries.

- Q: How does special steel contribute to the electrical industry?

- The electrical industry relies heavily on special steel to produce a wide range of components and equipment required for the generation, transmission, and distribution of electricity. Power transformers, for instance, heavily rely on special steel. These transformers are crucial for adjusting voltage levels in the electricity grid, allowing for efficient transmission and distribution of electricity. Special steel, thanks to its exceptional strength, durability, and magnetic properties, is employed to construct the cores of these transformers. The high magnetic permeability of special steel ensures minimal energy loss during the transformation process, resulting in more efficient power transmission. In addition, special steel is extensively used in the manufacturing of electrical conductors, such as wires and cables. These conductors are responsible for transporting electricity from power plants to various end-use applications. Special steel wires boast excellent conductivity and resistance to corrosion, making them ideal for transmitting electricity over long distances with minimal energy loss. Moreover, special steel is employed in the production of electrical connectors and terminals, ensuring secure and reliable connections between different electrical components. The electrical industry also relies on special steel for the fabrication of electrical motors and generators. The exceptional strength and magnetic properties of special steel contribute to the efficient conversion of electrical energy into mechanical energy, ensuring the smooth operation of motors and generators. Furthermore, special steel is used in the manufacturing of electrical switches, circuit breakers, and other protective devices, guaranteeing the safe and reliable functioning of electrical systems. Overall, special steel plays an indispensable role in the electrical industry by enabling the production of essential components and equipment necessary for the generation, transmission, and distribution of electricity. Its unique properties contribute to enhanced energy efficiency, reliability, and safety in electrical systems, cementing its status as an indispensable material in this industry.

- Q: How does special steel perform in corrosion fatigue conditions?

- Special steel is known for its exceptional performance in corrosion fatigue conditions. Corrosion fatigue refers to the combined effect of corrosion and cyclic loading, which can significantly degrade the mechanical properties of materials over time. However, special steel is specifically designed and alloyed to resist corrosion and maintain its structural integrity under these challenging conditions. The high corrosion resistance of special steel is achieved through the addition of alloying elements such as chromium, nickel, and molybdenum. These elements form a protective oxide layer on the surface of the steel, which acts as a barrier against corrosive agents. This oxide layer effectively prevents the penetration of moisture, oxygen, and other corrosive substances, reducing the likelihood of corrosion initiation and propagation. Furthermore, special steel exhibits excellent fatigue strength, allowing it to withstand cyclic loading without premature failure. Its unique microstructure, which is usually martensitic or austenitic, provides superior mechanical properties and resistance to fatigue crack initiation and propagation. This ensures that the material can endure repeated loading cycles without compromising its structural integrity. In addition to its corrosion resistance and fatigue strength, special steel also possesses good ductility and toughness. These properties are crucial in corrosion fatigue conditions as they enable the material to absorb and redistribute stress effectively, preventing localized stress concentrations that can lead to crack formation and propagation. Overall, special steel's exceptional performance in corrosion fatigue conditions can be attributed to its high corrosion resistance, fatigue strength, ductility, and toughness. These properties make it an ideal choice for applications where materials are subjected to cyclic loading and corrosive environments, such as offshore structures, marine equipment, and oil and gas pipelines.

Send your message to us

Grade AISI 304_316_321 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords