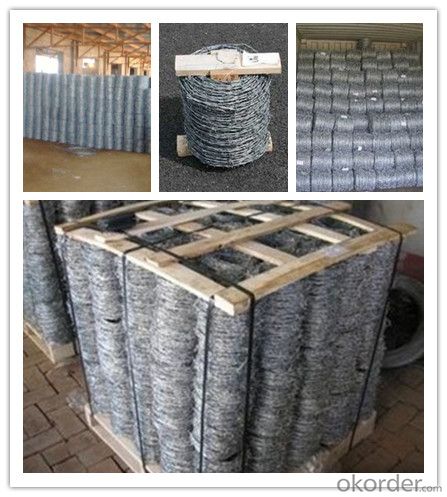

Galvanized Barbed Wire in 1.6mm to 2.7mm for Security Fence

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Twist Method: Double and Single Twist

Finish: Galvanized

Barbed Distance: 3" to 6"

Surface Treatment: Galvanized, PVC

Barbed Space: 3" to 6"

Barbed Wire Material: Low Carbon Steel Wire or High Carbon Steel Wire

Transport Package: in Roll with Label

Material: Steel Wire

Application: Protecting Mesh, Fence Mesh

Wire Gauge: 12x12 BWG

Barb Length: 12mm

Barbed Lenth: 12mm

Weight: 25kg, 50kg

Specification: 1.6mm to 2.7mm wire diameter

HS Code: 7223000

Product Description

Barbed wire, Alambre De pua

Material: low carbon Iron wire, hight carbon steel wire or high tensile wire, galvanized wire, PVC coated wire, stailess steel wire mesh, etc

Barb distance: 3-6inches; Barb length: 1-3cm

Surfacetreatment: Galvanized(hot dipped or ecectro) or PVC coated

Strand: Single or double; Technique: Single twisted and double twisted

Roll Weight: 1kg ,5kg, 10kg, 20kg, 30kg per roll

Packing: no any packing, or in carton

Application: Protecting, boundary, military, etc

Color: Silver, green or as required

If u want to know more, pls contact with us.

| Barbed Wire Specification | ||||

| Type | Wire Gauge (SWG) | Barb Distance (cm) | Barb Length (cm) | |

| Electric Galvanized Barbed Wire; Hot-dip zinc plating barbed wire | 10# x 12# | 7.5-15 | 1.5-3 | |

| 12# x 12# | ||||

| 12# x 14# | ||||

| 14# x 14# | ||||

| 14# x 16# | ||||

| 16# x 16# | ||||

| 16# x 18# | ||||

| PVC coated barbed wire; PE barbed wire | before coating | after coating | 7.5-15 | 1.5-3 |

| 1.0mm-3.5mm | 1.4mm-4.0mm | |||

| BWG11#-20# | BWG8#-17# | |||

| SWG11#-20# | SWG8#-17# | |||

| PVC PE coating thickness: 0.4mm-0.6mm; different colors or length are available at customers request. | ||||

- Q: i am putting in a ceiling fan. there is a black wire and a white wire along with a copper looking wire in the wall. on the fan there is a blue,white,and green. where do i connect this to the wires in the wall? running from a wall switch btw

- connect the fan black wire and the fan blue wire to the house black wire. then connect the white fan wire to the white house wire. connect the short green wire from the fan and fan bracket to the copper wire. the blue is the power wire to the light on the fan. Good luck...

- Q: How much does it cost to install telephone wires in your household?Does it cost around $200.00 ?

- Put them in yourself for free. It is only 4 wires and for a single line you only use two wires. Red and Green are the main telephone, yellow and black are for a second line. If you hook up the wires and you can't dial out, but have a dial tone, switch the wires.

- Q: US electrical tech question from a non electrically minded fag. I have a dimmer controlling a light and a single light switch controlling a fan. There is one blue wire going to the dimmer and one blue wire going to the switch. There is one black wire going to a 2nd terminal on the switch, which is also connected to a 2nd wire leading to the 2nd terminal on the dimmer. Now tell me how to wire an outlet into this ******* mess.Inb4 op is a fag, inb4 op should post this somewhere else, inb4 turn the power on and touch the wires, inb4 op can't inb4

- From the sounds of your description, you are in the UK or a country where they use UK wireing system and standards. If ythis so and by outlet you mean a receptacle, then you do not wire an outlet to the lighting circuit. Receptacles are wired on separate circuits only meant for receptacles. Take CRISDRUMCHICK's advice, hire a reputable, qualified electrician. You do not know enough to do the job safely. Inb4 op is a fag, inb4 op should post this somewhere else, inb4 turn the power on and touch the wires, inb4 op can't inb4 - What is this nonsense? It looks and is degrading and uncalled for in Yahoo Answers.

- Q: Why do two parallel wires carrying currents in opposite directions repel each other?

- Each of the wires is under the influence of the circular magnetic field produced by the other wire. If you apply Fleming's left hand rule, you will realise that the mechanical force experienced by each wire under the influence of the magnetic field of the other is in opposite direction. So, as the mechanical force on each wire pulls it apart from the other wire, there is repulsion between the two wires. Was this helpful?

- Q: i have a 2004 Isuzu Rodeo I cannot find the wiring harness color codes for it. i need the Left Rear positive negative colors the Right Rear positive negative colors. Thank You.

- Holden Rodeo Wiring Diagram

- Q: I recently bought a set of DT Moto emergency lights for my pickup and after installing them i found when i went to wire them to my battery the wire was too short. I didn't install the grille lights just the visor. Could i cut wires from the grille set and wire them to extend the visor light wire?

- I'm looking online to find out what DT Moto lights are. Ok, I see what they are. I didn't know the brand name. LED lights in general are not high current, so they probably use lamp cord. I want to explain something to you about polarity. Electronic circuits are sensitive to the polarity of the DC electricity. The positive (+) and the negative (-) connections must be observed. So many people have absolutely no clue about this. There are just two wires. But if you extend them, you have a 50-50 chance of wiring correctly or incorrectly. There is only one allowable way. If wrong, it WON'T work, and probably will blow up the circuitry. So connection to battery or cigarette lighter plug is extremely important not to reverse the polarity. If just the LED lights got reversed, they wouldn't light, but they wouldn't be injured. Just reverse the wiring. But to the 12 volt source, polarity can't be wrong. Not for an instant. If you look closely at the insulation, you will see that one wire has smooth insulation, and one wire either has milti-ribbed insulation, or a single rib down the side. If you extend wiring, make sure to connect smooth to smooth and ribbed to ribbed. Wires should be soldered with electronic solder and the joints covered with heat shrink tubing. No crimped barrel connectors, or twisted bare wires with tape, or house wiring wire nuts. These methods all beg for failure. I don't know about robbing wire from one place and connecting to another. Is the one wire actually too long? You'll never need it? I guess you could take it. But me personally, I'd go get some wire from a lamp store. Match the wire conductor gauge (size), not the insulation size. Most lamp cord is 18 gauge. Some is 16 gauge. You can get 14 gauge or even 12 gauge. Thicker is a smaller number. Places that install car audio systems often have/sell thicker lamp cord. Have I told you enough?

- Q: My starter I replaced has 3 wires, two red and one black. Where does each wire go? Pictures would be very helpful if possible

- based upon the gauge you have... i do no longer think of you're placing it to a mustang yet i detect genuine low-priced air stress gauges are very deceptive.. your 5.0 may well be 50 psi (if it relatively is prolonged each and every of how out) and is a great way overinflated. the properly suited tire stress is the two interior the glove container on a plaque interior the door or is a sitcker on the rear door section.. yet stress could desire to be form of 32 psi (220 kps for our metric friends) on your motor vehicle in case you haven't any longer pushed it for greater effective than 8 hours...

- Q: could someone teach or explain to me how to hook up the 1st one, i do not understand what is happening there. How do you connect thoes wires to the main wire??? the distribution?

- Ok, first thing you want to do is, for each subwoofer, wire a negative and positive together. You can use regular speaker wire to do that (well you're supposed to anyway). After that, you will have a negative and positive terminal left on each subwoofer. What you need to do is run a speaker wire from each of the terminals, so you have 6 different wires from 6 separate terminals. Make note of the 3 positive wires and the 3 negative wires. Now what you do is simply twist together the 3 positive wires together, so you have 1 positive wire. Connect that positive wire to the positive terminal of the amp (if it's a 1 channel amp. If it's a 2 channel, connect it to a bridged channel on the positive terminal. Or however you want.) Do the same for the 3 negative wires. Twist them together to have 1 negative wire, and connect it to the negative terminal on the amp. Finished! That kind of wiring is called Series wiring, by the way. The other kind is called Parallel wiring.

- Q: Why is thin strand wire better for powering car audio?

- It's purely for flexibility. Solid wire would be just as effective, but it's about impossible to route through a car. In response to Rolo's answer -- Skin effect is a high frequency AC phenomenon - not an issue with DC, or any frequency in the audible spectrum for that matter. High strand count in car audio wire is purely for flexibility.

- Q: What is a wiring harness?

- A wiring harness is a plug in device most often used on your in dash head unit, it makes wiring easier because you can wire it while sitting down with plenty of lite then when you get in the car you can just plug it into the cars wiring and your ready to go...lots of modern autos also use a wiring harness for the speaker wires the advantages are less though because your only dealing with two wires.

Send your message to us

Galvanized Barbed Wire in 1.6mm to 2.7mm for Security Fence

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches