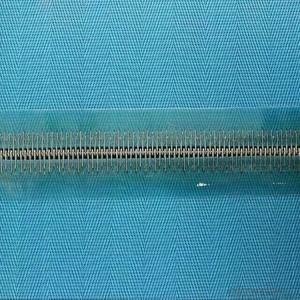

Stainless Steel Wire Fence

Stainless Steel Wire Fence Related Searches

Stainless Steel Fence Stainless Steel Fencing Stainless Steel Tie Wire Stainless Steel Wires Stainless Steel Wire Grid Stainless Steel Jewellery Wire Stainless Steel Wall Stainless Steel Wire Basket Galvanized Steel Fence Stainless Steel Wire Shelving Stainless Steel Wire Rack Stainless Steel Gate Stainless Steel Wire Shelves Stainless Steel Flange Stainless Steel Pipe Flange Wire Mesh Stainless Steel Stainless Steel Mig Wire Chicken Wire Stainless Steel Cast Iron Fence Stainless Steel Wire Wheel Stainless Steel Fan Stainless Steel Flue Pipe Stainless Steel Rope Chain Stainless Steel Chicken Wire Mesh Stainless Steel Signage Stainless Steel Siding Stainless Steel Roofing Stainless Steel Wire Uk Stainless Steel Door Stainless Steel Curb ChainStainless Steel Wire Fence Supplier & Manufacturer from China

Stainless Steel Wire Fence, known for its durability and resistance to corrosion, is a popular choice for security and safety applications. Made from high-quality stainless steel, these fences are designed to withstand harsh weather conditions and provide a long-lasting barrier. They are commonly used in various settings, such as residential properties, commercial buildings, and industrial facilities, to protect against unauthorized access and potential threats. Their sleek and modern appearance also makes them an aesthetically pleasing option for enhancing the visual appeal of any property. As a wholesale supplier, Okorder.com offers a vast inventory of Stainless Steel Wire Fence, catering to the diverse needs of customers across different industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Stainless Steel Wire Fence products they provide meet the highest standards and are available at competitive prices.Hot Products