FRP Roofing Panel S10

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 1000m2/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

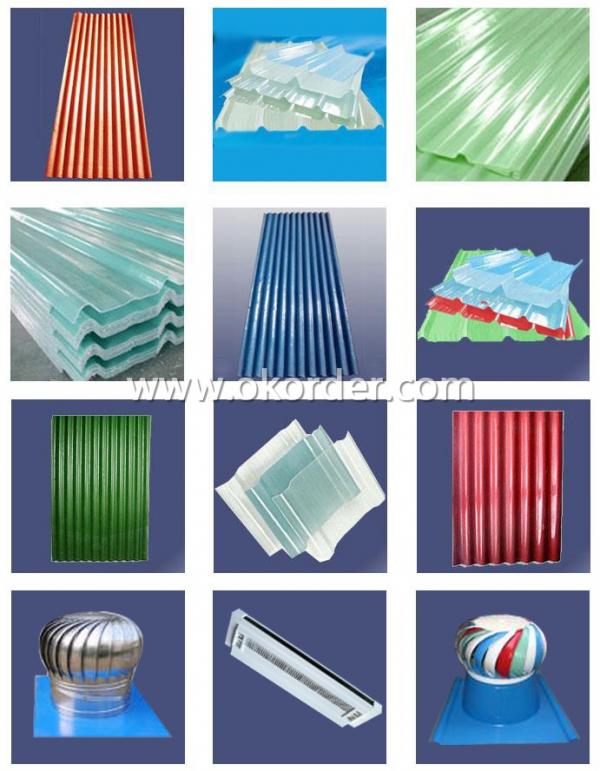

Specification of FRP Roofing Panel S10

Thickness:1.0mm Color:sky blue, dark blue, clear, light green, dark green, opal, etc.Ordinary Wave: 840-210

Length:No limit but with the consideration of transportation

Introduction of FRP Roofing Panel S10

As HIGOAL's core product,FRP plastic sheet , Roof translucent panel, roof skylight ,sky roofing has been produced for over 14 years and has experienced many improvements which is an excellent lighting materials of steel building, New generation strengthened skylight sheet.

Brief Description of FRP Roofing Panel S10:

1). Anti-aging resin, longer duration of use.

2). Strong UV protection

3). High light transmittance

4). Less bubbles, good impact strength and flexural strength to withstand typhoons and hail hit.

5). Good Performance of film, flat and smooth. Dust is easy to be removed.

6). High-quality E-glass fibers, good light transmittance and water resistance

7). Good corrosion resistance, suitable for acid and alkali environment.

8). Even thickness, consistent mechanical properties.

Features of FRP Roofing Panel S10 :

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%

2) Weather resistant and Self-clean ability

3) Excellent yellowness resistance

4) Strong impact resistant and low bending rate

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable

for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

- Q: Are FRP roofing panels resistant to warping or deformation from heavy loads?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to warping or deformation from heavy loads. FRP panels are known for their high strength-to-weight ratio, which allows them to support heavy loads without distorting or bending. The reinforcement of fiberglass within the plastic matrix provides excellent structural integrity, making FRP panels highly resistant to warping or deformation even under extreme loads. Additionally, FRP panels are designed to be rigid and durable, capable of withstanding heavy snow loads, foot traffic, or other weighty objects without compromising their shape or structural integrity. However, it is important to note that the exact resistance to warping or deformation may vary depending on the specific manufacturer, design, and installation of the FRP roofing panels. It is always advisable to consult the manufacturer's specifications and guidelines to ensure proper load-bearing capacity and installation practices for the specific FRP roofing panels being used.

- Q: Can FRP roofing panels be used for solar panel installations?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can indeed be used for solar panel installations. FRP panels are known for their durability, thermal stability, and resistance to corrosion, making them suitable for supporting solar panels. They are lightweight yet strong, which makes installation easier and reduces the load on the roof structure. Additionally, FRP panels have excellent UV resistance, which is crucial for protecting the underlying solar cells from sun damage. The smooth surface of FRP panels also aids in the efficient performance of solar panels by reducing dirt buildup and facilitating self-cleaning. Overall, FRP roofing panels are a reliable and cost-effective choice for supporting solar panel installations.

- Q: Are FRP roofing panels suitable for university campuses or educational buildings?

- Yes, FRP roofing panels are suitable for university campuses or educational buildings. FRP (Fiberglass Reinforced Plastic) roofing panels offer numerous benefits such as durability, lightweight construction, resistance to extreme weather conditions, and low maintenance requirements. These factors make FRP roofing panels a reliable and cost-effective choice for educational institutions seeking long-lasting and sustainable roofing solutions.

- Q: Are FRP roofing panels resistant to cracking or splitting?

- FRP roofing panels exhibit exceptional resistance to cracking or splitting due to their composition of fiberglass and plastic resin. This combination yields a robust and enduring material capable of withstanding diverse weather conditions and mechanical strain. The fiberglass reinforcement bolsters the panels' strength and rigidity, rendering them highly resistant to cracking or splitting, even when subjected to substantial loads or impacts. Moreover, the design of FRP roofing panels incorporates flexibility, further minimizing the likelihood of cracks or splits. Ultimately, FRP roofing panels offer a dependable and enduring solution that withstands external forces while maintaining its structural integrity.

- Q: Can FRP roofing panels be used for greenhouses or agricultural tunnels?

- Greenhouses or agricultural tunnels can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess various qualities that make them well-suited for these applications. Firstly, they have a lightweight composition, making installation easy and reducing the strain on the structure. This becomes particularly crucial in greenhouse or tunnel construction, as the roof must support plant growth and potentially handle heavy snow loads. Secondly, FRP panels exhibit remarkable durability and corrosion resistance, which is indispensable in withstanding the harsh conditions typically encountered in agricultural environments. They also withstand UV radiation, ensuring long-lasting performance even under direct sunlight. Additionally, FRP panels facilitate excellent light transmission, allowing plants to receive adequate sunlight for photosynthesis. This factor is critical for plant growth and productivity in greenhouses or agricultural tunnels. Furthermore, the panels can be manufactured with different levels of light diffusion to control sunlight intensity and prevent plant scorching or shadowing. Moreover, FRP panels possess commendable thermal insulation properties, helping to maintain the desired temperature and humidity levels inside the greenhouse or tunnel. This aspect plays a vital role in creating an optimal environment for plant growth and safeguarding crops against extreme weather conditions. In conclusion, FRP roofing panels offer numerous advantages, such as their lightweight nature, durability, resistance to corrosion and UV radiation, high light transmission, and thermal insulation properties. Consequently, they serve as an excellent choice for greenhouses or agricultural tunnels.

- Q: Are FRP roofing panels flexible?

- FRP (Fiberglass Reinforced Plastic) roofing panels are not typically considered flexible. While they do have some degree of flexibility, they are generally rigid and sturdy. FRP roofing panels are designed to provide strength, durability, and resistance to impact, weather, and UV rays. However, it is worth noting that the flexibility of FRP panels can vary depending on the specific manufacturer and the thickness of the panel. In certain cases, thinner FRP panels may exhibit some level of flexibility, but they are still far less flexible compared to other roofing materials, such as PVC or TPO membranes.

- Q: Are FRP roofing panels resistant to water leaks?

- Yes, FRP roofing panels are highly resistant to water leaks. The fiberglass-reinforced plastic material used in FRP panels is inherently waterproof and does not absorb water. Additionally, the panels are designed with overlapping edges and sealants to provide a secure and watertight barrier, preventing any leaks or water seepage.

- Q: Can FRP roofing panels be customized in terms of size and color?

- Yes, FRP roofing panels can be customized in terms of both size and color. FRP stands for fiberglass reinforced plastic, which is a versatile material that can be easily molded and fabricated to meet specific requirements. In terms of size, FRP roofing panels can be manufactured in various lengths, widths, and thicknesses to fit the specific dimensions of a building or project. Additionally, FRP panels can be custom-made in different colors to match the aesthetic preferences or branding requirements of the customer. The customization options for FRP roofing panels make them a popular choice for a wide range of applications, from industrial and commercial buildings to residential projects.

- Q: Can FRP roofing panels be used for outdoor classrooms or educational facilities?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for outdoor classrooms or educational facilities. FRP panels are known for their durability, weather resistance, and ability to withstand harsh outdoor conditions. They are also lightweight, making them easy to install and maintain. Additionally, FRP panels offer excellent thermal insulation properties, which can contribute to creating a comfortable learning environment. Their versatility allows them to be used for various applications, including roofing, wall cladding, and skylights. FRP roofing panels are also available in different colors and designs, providing aesthetic options that can enhance the visual appeal of educational facilities. Overall, FRP roofing panels are a viable choice for outdoor classrooms or educational facilities due to their durability, weather resistance, insulation properties, and aesthetic options.

- Q: Can FRP roofing panels be used for warehouses?

- Warehouses can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess the qualities of being lightweight, durable, and resistant to corrosion, thereby making them an exceptional selection for commercial and industrial purposes like warehouses. Moreover, they offer superb safeguarding against severe weather elements such as UV rays, rain, and snow. Furthermore, installing and upkeeping FRP panels is hassle-free, rendering them a financially prudent roofing alternative for warehouses.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1999 |

| Annual Output Value | Above US$ 300,000 |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9002:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

FRP Roofing Panel S10

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 1000m2/MONTH m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords