FRP Roofing Panel - High Quality Corrugated GRP Plastic Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

The FRP roof tile using in factories, warehouses, car parks, agricultural, freezer, food processing plants, restaurants, laboratory, heat-insulation sheds, weather corridors, lighting sheds, sun sheds, greenhouses, etc.

FEATURES

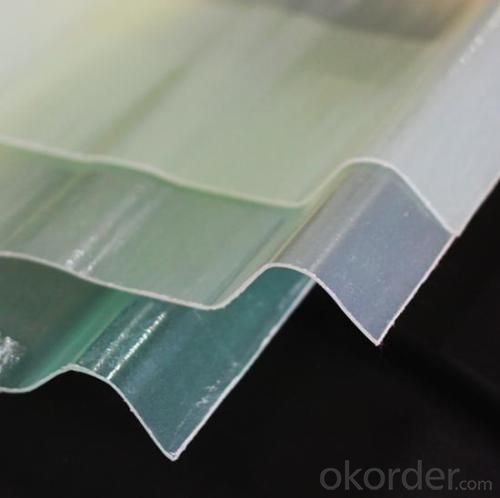

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATION

Name: | FRP Roofing |

Material: | Fiberglass |

Width: | 880mm/1050mm |

Effective width: | 800mm/960mm |

Wave length: | 160mm |

Wave height: | 30mm |

Pitch: | 220mm |

Thickness: | 3/2.5mm |

Length: | Customized but must be a multiple of wave pitch |

Color: | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application: | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ: | 1000 Square meter |

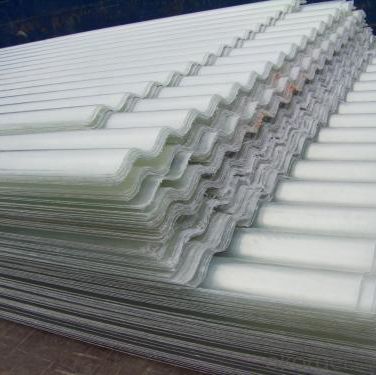

PICTURES

- Q: Are FRP roofing panels resistant to oil and gas exposure?

- Yes, FRP roofing panels are resistant to oil and gas exposure.

- Q: Do FRP roofing panels require a specific type of roof hatch or access door?

- FRP (Fiberglass Reinforced Plastic) roofing panels do not require a specific type of roof hatch or access door. However, it is recommended to use a roof hatch or access door that is compatible with the type of roofing system being installed. The choice of roof hatch or access door should take into consideration factors such as the size and weight of the panels, as well as any specific installation requirements. It is important to consult with the manufacturer or a roofing professional to ensure the chosen roof hatch or access door is suitable for use with FRP roofing panels.

- Q: Are FRP roofing panels resistant to weathering?

- Yes, FRP roofing panels are highly resistant to weathering. They are designed to withstand various weather conditions, including extreme heat, cold, rain, wind, and UV radiation. The durable construction and protective coatings of FRP panels make them resistant to fading, cracking, peeling, and other forms of weather-related damage, ensuring long-lasting performance and minimal maintenance requirements.

- Q: Are FRP roofing panels prone to scratches?

- FRP roofing panels are generally resistant to scratches, thanks to their strong and durable composition. However, like any other surface, they can still get scratched under extreme circumstances or due to improper handling. Overall, with proper care and maintenance, FRP roofing panels should remain largely scratch-free.

- Q: Are FRP roofing panels durable?

- Indeed, FRP roofing panels exhibit remarkable durability. Crafted to endure a multitude of weather conditions, they boast resistance against corrosion, UV rays, and impact. Renowned for their robustness and longevity, FRP roofing panels have become a favored option for industrial and commercial edifices. Their ability to resist warping, cracking, and fading ensures their enduring sturdiness. Moreover, the minimal maintenance required by FRP roofing panels enhances their longevity and fortitude.

- Q: What is the insulation value of FRP roofing panels?

- The insulation value of FRP roofing panels can vary depending on the specific type and thickness of the panels. However, generally, FRP roofing panels have a lower insulation value compared to other roofing materials such as insulated metal panels or foam panels.

- Q: Are FRP roofing panels compatible with different insulation materials?

- Indeed, various insulation materials can be used in conjunction with FRP roofing panels. FRP, an abbreviation for fiberglass reinforced plastic, is an exceedingly adaptable and long-lasting substance. It harmonizes well with a diverse array of insulation materials, including polyurethane foam, polystyrene, mineral wool, and more. This compatibility grants an extensive selection of choices for attaining thermal insulation and energy efficiency within structures. To guarantee appropriate installation and compatibility with FRP roofing panels, it is crucial to take into account the specific prerequisites and suggestions of the insulation manufacturer, as well as seek guidance from roofing professionals.

- Q: Are FRP roofing panels prone to condensation?

- FRP roofing panels, also known as fiberglass reinforced plastic roofing panels, are generally not prone to condensation when installed correctly. These panels are designed to be water-resistant and have good insulation properties, reducing the likelihood of condensation forming on their surface. However, it is important to note that condensation can occur in any type of roofing system if certain conditions are present. One of the main factors contributing to condensation is a significant difference in temperature between the interior and exterior of a building. This temperature differential can cause moisture in the air to condense on cooler surfaces, such as the underside of the roofing panels. To minimize the risk of condensation, proper ventilation and insulation should be implemented during the installation process. Adequate insulation helps maintain a consistent temperature within the building, reducing the potential for condensation. Additionally, proper ventilation allows for the circulation of air, preventing moisture buildup and reducing the likelihood of condensation forming on the roofing panels. Regular maintenance and inspection of the roofing system are also crucial in identifying any potential issues that may lead to condensation. If condensation is observed, it is important to address the underlying cause promptly to prevent damage to the roof and the building. Overall, while FRP roofing panels are generally not prone to condensation, it is essential to consider proper installation, insulation, ventilation, and regular maintenance to minimize the risk of condensation occurring in any roofing system.

- Q: Which is better, the sun board or the light board?

- Production process: PC sunlight board is co extrusion molding, the production process is more complicated; the sunlight board is one of the lighting board, most of the lighting board is made of FRP, and the said sunlight board is made of PC (polycarbonate);Service life: PC in the service life is 10 years and 15 years or even 20 years, lighting plate warranty good FRP for 10 years.

- Q: Are FRP roofing panels resistant to bird pecking?

- FRP roofing panels are known for their ability to withstand bird pecking. Unlike asphalt shingles or wooden panels, FRP panels are highly durable and strong, minimizing the risk of damage caused by bird pecking. Additionally, the smooth surface of FRP panels acts as a deterrent for birds, discouraging them from perching and pecking. However, it is important to be aware that while FRP panels are resistant to bird pecking, they may still experience minor scratches or damage if birds repeatedly target a specific area. Regular inspection and maintenance are crucial to ensure the longevity and effectiveness of FRP roofing panels.

Send your message to us

FRP Roofing Panel - High Quality Corrugated GRP Plastic Roofing Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords