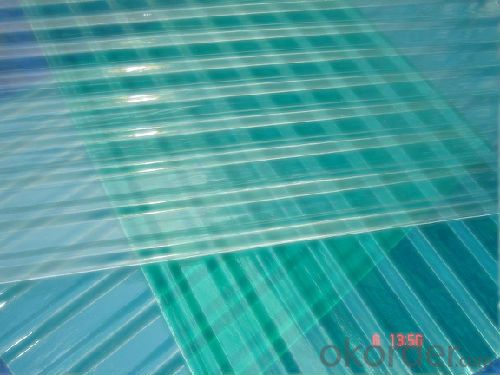

FRP Roofing Panel - Reinforced Glass Fiber Corrugated Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

products are resistant to the corrosion of gas and liquid of acids, alkalis, salt, and organic solvent so that they can avoid the problem of rusting steel and rotten wood.

2.Characteristics

Light weight and high intensity

fiberglass products are molded through the solidification of fiberglass and resin under high temperature. Its density is only one quarter of that of steel, and two-thirds of that of aluminum. But its intensity is ten times that of PVC, exceeding the aluminum products and reaching the level of common carbon steel. Due to its light weight, the products require less base support and possess the features of easy installation and low costs.

Inflaming Retarding

The common oxygen index of common fiberglass products is above 32 (according to GB8924). By design, the flame spreading index of the high inflaming retarding ethylene products is below 10, which meets the requirements of engineering fire resistance for safety.

Collision Resistance and Fatigue Resistance

fiberglass products can resist collision and keep the original shape after repeated bending so as to be used as spring.

Age Resistance

The normal longevity is more than 20 years. The research result shows that the intensity will still retain more than 85% after 20 years’ exposure to the atmosphere.

3.Application

Good appearance and Easy Maintenance

The color slurry offiberglass products is mixed with resin to make the color bright and difficult to fade. No painting is needed on the surface which is clean after washing.

4.FAQ

Packaging & Delivery

Packaging Details: | Poly bag, then loading into carton box |

Delivery Detail: | 20 days after confirm order |

- Q: Can FRP roofing panels be installed on retail shopfronts or storefronts?

- Yes, FRP roofing panels can be installed on retail shopfronts or storefronts. These panels are lightweight, durable, and have excellent weather resistance, making them a suitable choice for commercial applications. Additionally, FRP panels offer aesthetic appeal with a variety of colors and finishes available, enhancing the overall appearance of the shopfront or storefront.

- Q: Are FRP roofing panels recyclable?

- Indeed, FRP roofing panels can be recycled as they are composed of a blend of fiberglass and plastic resin. The recycling method may differ based on the panels' unique composition and manufacturer. As a whole, FRP roofing panels can be repurposed into fresh materials or goods. The fiberglass component can be recovered and utilized for insulation or reinforcement purposes in other composite materials. Similarly, the plastic resin can be recycled and employed in the manufacturing of new plastic products. Recycling FRP roofing panels not only aids in waste reduction and resource conservation, but also advances sustainability within the construction sector.

- Q: Do FRP roofing panels provide good insulation?

- Yes, FRP roofing panels provide good insulation.

- Q: Can FRP roofing panels be used for both new construction and roof replacements?

- FRP roofing panels are suitable for new construction as well as roof replacements. They can be easily installed on different types of structures, such as residential, commercial, and industrial buildings. These panels are lightweight, durable, and have exceptional weather resistance, making them ideal for new roofs or replacing old or damaged ones. Moreover, their low maintenance requirements and simplicity of installation make FRP panels a cost-effective choice for any construction or replacement endeavor.

- Q: How are FRP roofing panels secured to the roof structure?

- FRP roofing panels are typically secured to the roof structure using screws, nails, or adhesive. These panels are designed with pre-drilled holes that allow for easy attachment to the underlying framework. Additionally, sealants may be used to ensure a watertight seal between the panels and the roof structure to prevent any leakage.

- Q: Do FRP roofing panels require any specific type of underlayment?

- Yes, FRP roofing panels typically require a specific type of underlayment. It is recommended to use a moisture-resistant and non-combustible underlayment, such as a high-density polyethylene (HDPE) or a fiberglass mat, to ensure proper installation and to enhance the longevity of the roofing system.

- Q: Can FRP roofing panels be used in areas with high levels of noise pollution?

- FRP roofing panels are indeed applicable in areas with excessive noise pollution. They possess remarkable acoustic properties, allowing them to proficiently absorb sound and diminish noise levels. Consequently, they are highly suitable for implementation in boisterous surroundings like industrial zones, airports, or highways. Moreover, FRP panels can be customized to incorporate supplementary soundproofing characteristics, such as insulation materials or acoustic barriers, in order to amplify their capacity for reducing noise. In summary, FRP roofing panels present a feasible solution for alleviating noise pollution in diverse environments.

- Q: Do FRP roofing panels require any special safety measures during installation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require special safety measures during installation. Here are some important safety measures to consider: 1. Personal Protective Equipment (PPE): Installers should wear appropriate PPE, including safety glasses, gloves, and non-slip footwear, to protect themselves from potential hazards. 2. Fall Protection: Since installation of roofing panels often involves working at heights, fall protection equipment such as harnesses, lanyards, and anchor points should be utilized to prevent falls. It is crucial to follow proper fall protection guidelines and regulations. 3. Handling Panels Safely: FRP panels can be heavy and fragile, so it is important to handle them with care. Use proper lifting techniques and tools, such as lifting straps or suction cups, to avoid strains or injuries. Take precautions to prevent panels from falling or breaking during transportation or installation. 4. Secure Work Area: Ensure that the work area is properly secured and roped off to prevent unauthorized access. This will help minimize the risk of accidents or injuries to both installers and bystanders. 5. Weather Conditions: Pay attention to weather conditions during installation. Strong winds, rain, or icy surfaces can increase the risk of accidents. It may be necessary to reschedule the installation if weather conditions pose a safety hazard. 6. Training and Supervision: Installers should be adequately trained in the proper installation techniques and safety procedures specific to FRP roofing panels. Always have a qualified supervisor or experienced installer oversee the process to ensure compliance with safety measures. By following these special safety measures, the risk of accidents or injuries during the installation of FRP roofing panels can be significantly reduced, ensuring a safe working environment for all involved.

- Q: Can FRP roofing panels be used in convention centers or exhibition halls?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in convention centers or exhibition halls. FRP panels are a popular choice for roofing applications due to their lightweight, durable, and corrosion-resistant properties. They are also available in various colors, textures, and designs, allowing for aesthetic flexibility. Moreover, FRP panels offer excellent thermal insulation and can withstand extreme weather conditions, making them suitable for both indoor and outdoor use. Additionally, FRP panels are easy to install and maintain, making them a cost-effective choice for large-scale commercial buildings like convention centers or exhibition halls.

- Q: Can FRP roofing panels be used for both residential and commercial storefronts?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for both residential and commercial storefronts. FRP roofing panels are known for their durability, lightweight nature, and excellent resistance to corrosion, making them suitable for various applications. They are commonly used in both residential and commercial settings due to their versatility and affordability. FRP roofing panels provide effective protection against weather elements, including UV rays, rain, and hail, ensuring the longevity of the roof. Additionally, FRP panels come in a variety of colors and designs, allowing for customization according to the aesthetic requirements of both residential and commercial storefronts. Overall, FRP roofing panels offer a reliable and cost-effective roofing solution for both residential and commercial applications.

Send your message to us

FRP Roofing Panel - Reinforced Glass Fiber Corrugated Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords