2.0mm Thick FRP Panels for Trailer Roofs - Fiber Reinforced Plastic Sheet Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber Reinforce Plastic Sheet Panel with 2.0 mm Thinkness

Description

FRP sheets are made of fiberglass and polyester resin and continuously molded by machine.

They are characterized by high-light transmittance, light-weight, high-strength, corrosion resistance, impact resistance, anti-ultraviolet, anti-

static, heat preservation and insulation, accurate section dimensions and controllable cutting length. They can be used with various profiling panels and galvanized sheets.

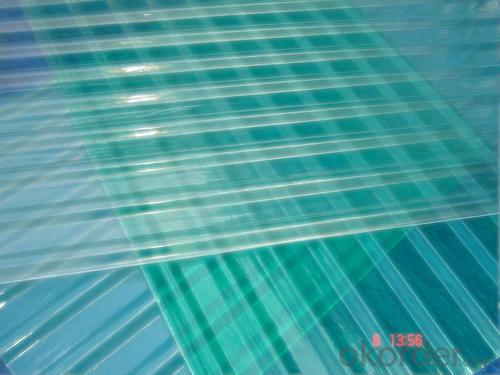

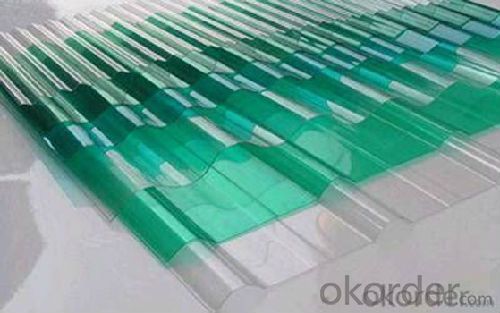

Photos

Product Traits

Good tenacity. No cracking phenomenon when driving nails in roof installation.

Having close combing with color steel plate. Cross-section thickness is uniform. The shape of FRP is consistent with steel plate.

Transmittance loss rate is low. No yellowing phenomenon after long term service.

Thermal expansion coefficient is close to that of steel plate. No cracking and water leakage in nail driving place because of expand with heat and contract with cold.

Light through FRP assumes scattering shape and gentle.

Bright and clean appearance. No distinct air bubble and cracking on FRP.

Anti-ultraviolet and anti-chemistry corrosion.

Anti-aging and anti-pulverization.

Long service life.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

Easy to maintain.

High strength.

Long service life.

Easy to install.

Good light transmittance.

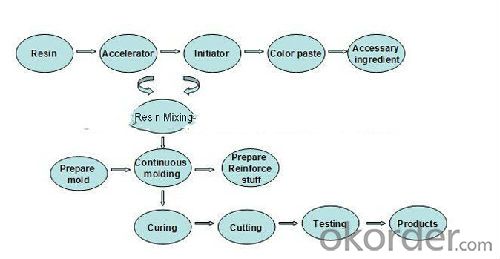

Production Process

Specification

Physical properties:

| Tensile strength | 80-100Mpa |

| Flexural strength | 0-110 Mpa |

| Density | 1.4-1.6g/cm³ |

| Pasteur | ≥40 |

| Heat conductivity factor | 0.67-0.96kv/m.h.°C |

| Temperature range | -40°C—+60°C |

| Water absorption | 24 hours ≤0.32% |

| Wind loading rating | below 8 levels |

| Curing degree | ≥82% |

Product classification:

Plate type | thickness(mm) | width(mm) | |

Flat plate | 0.7-4.0 | ≤1400 | |

Sine wave | 0.7-4.0 | ≤1200 | |

Trapezoidal wave | 0.7-4.0 | Mating with pressure plate | |

Fire resistance | Ordinary type | ||

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Can FRP roofing panels be used in areas with extreme temperatures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in areas with extreme temperatures. FRP panels are known for their excellent thermal insulation properties and can withstand a wide range of temperatures, both hot and cold. They are designed to resist thermal expansion and contraction, making them suitable for areas with extreme temperature fluctuations. Additionally, FRP panels have high UV resistance, which allows them to withstand intense sunlight and prevent color fading or degradation. However, it is important to ensure that the specific FRP roofing panels being used are rated for the specific temperature extremes of the area in question to ensure optimal performance and longevity.

- Q: Can FRP roofing panels be used in cold climates?

- Yes, FRP roofing panels can be used in cold climates. FRP (Fiberglass Reinforced Plastic) panels are known for their durability and resistance to extreme weather conditions, including cold temperatures. They can withstand freezing temperatures and provide effective insulation, making them suitable for use in cold climates.

- Q: Are FRP roofing panels resistant to chemicals or acids?

- FRP roofing panels, known as Fiberglass Reinforced Plastic, possess a general resistance to chemicals and acids. These panels are manufactured using a blend of fiberglass and resin, endowing them with remarkable corrosion resistance. Consequently, they can endure exposure to various chemicals and acids without suffering deterioration or substantial harm. Due to these characteristics, FRP roofing panels are deemed suitable for industrial or commercial purposes that involve potential contact with chemicals or acids. Nevertheless, it is advisable to verify the specific compatibility of FRP panels with the substances in question to guarantee optimal performance and longevity.

- Q: Are FRP roofing panels suitable for barns or agricultural buildings?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for barns or agricultural buildings. FRP panels are known for their durability, strength, and resistance to various weather conditions, making them ideal for structures that require reliable protection against the elements. Additionally, FRP panels are lightweight and easy to install, making them a practical choice for agricultural buildings. They also offer excellent UV resistance, which helps prevent damage from prolonged exposure to sunlight. Furthermore, FRP panels are highly resistant to chemicals, making them suitable for barns where exposure to corrosive substances like fertilizers or animal waste is common. Overall, FRP roofing panels provide a cost-effective and long-lasting roofing solution for barns and agricultural buildings.

- Q: Aluminum plate Eterpan lighting plate are used in what place

- The use of aluminum plate and Aitken board should be roughly the same as the inner and outer walls and partitions!

- Q: Are FRP roofing panels prone to expansion and contraction?

- FRP roofing panels, made of fiberglass reinforced plastic, exhibit excellent dimensional stability due to their composition. Unlike metal or wood, they have minimal tendency to expand or contract. Although all materials experience some degree of expansion and contraction caused by temperature and humidity variations, FRP panels are engineered to minimize these effects. The reinforcement of fiberglass in FRP panels ensures even stress distribution, preventing warping or bowing due to thermal expansion. Moreover, manufacturers often apply UV-resistant coatings to FRP panels, safeguarding them from sun damage. This preserves their structural integrity and prevents significant expansion or contraction resulting from prolonged heat exposure. Nevertheless, it is essential to note that extreme temperature fluctuations or incorrect installation can still cause slight expansion or contraction in FRP panels. To mitigate these potential issues, it is crucial to adhere to the manufacturer's guidelines and employ proper installation techniques. Additionally, regular inspections and maintenance are necessary to detect and rectify any emerging problems before they escalate.

- Q: Can FRP roofing panels be installed on both residential and commercial pergolas?

- Yes, FRP roofing panels can be installed on both residential and commercial pergolas. FRP panels are versatile and can be used in various applications, including pergolas, due to their durability, lightweight nature, and resistance to weather and UV rays.

- Q: How do FRP roofing panels compare to PVC roofing materials?

- FRP roofing panels and PVC roofing materials have several differences that make them suitable for different applications. FRP (Fiber Reinforced Polymer) roofing panels are made from a combination of fiberglass and resin, while PVC (Polyvinyl Chloride) roofing materials are made from a synthetic plastic polymer. One major difference between FRP roofing panels and PVC roofing materials is their strength and durability. FRP panels are known for their high strength-to-weight ratio and resistance to impact, making them a popular choice for industrial and commercial buildings. On the other hand, PVC roofing materials are more flexible and lightweight, making them suitable for residential applications or curved roof structures. Another difference is their resistance to weathering and UV radiation. FRP roofing panels usually have a protective gel coat that provides excellent resistance against UV rays, preventing discoloration and deterioration over time. PVC roofing materials may also have UV stabilizers, but they may degrade over time, leading to discoloration and reduced lifespan if not properly maintained. In terms of installation and maintenance, PVC roofing materials are generally easier to install due to their flexibility and lightweight nature. They can be easily bent or cut to fit specific shapes and sizes, making them ideal for DIY projects. FRP roofing panels, on the other hand, may require professional installation due to their rigidity and specific installation techniques. Cost-wise, PVC roofing materials are generally more affordable compared to FRP roofing panels. PVC is a widely available material, making it cost-effective for residential projects. FRP roofing panels, on the other hand, are often used in industrial or commercial settings and may carry a higher price tag due to their strength and durability. In conclusion, the choice between FRP roofing panels and PVC roofing materials depends on the specific requirements of the project. FRP panels are known for their strength, durability, and resistance to impact, making them suitable for industrial and commercial applications. PVC roofing materials, on the other hand, are more flexible, lightweight, and cost-effective, making them ideal for residential or curved roof structures.

- Q: Can FRP roofing panels be used for restaurants?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for restaurants. FRP panels are lightweight, durable, and have excellent resistance to corrosion and UV radiation. These characteristics make them ideal for use in food establishments where hygiene, safety, and longevity are crucial. Additionally, FRP panels are easy to clean and maintain, which is essential for restaurants where cleanliness is a top priority. They also offer good insulation properties, helping to regulate temperature and reduce energy consumption. Overall, FRP roofing panels are a suitable choice for restaurants due to their durability, low maintenance requirements, and ability to meet the specific needs of the food industry.

- Q: Can FRP roofing panels be used for libraries?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for libraries. FRP panels are a versatile roofing material that offer numerous benefits for various applications, including libraries. Firstly, FRP panels are lightweight yet highly durable, making them ideal for roofing projects. They are resistant to corrosion, UV rays, and extreme weather conditions, ensuring long-lasting protection for the library building. This durability also reduces the need for frequent maintenance and replacement, saving costs in the long run. Secondly, FRP panels are available in various designs, colors, and finishes, allowing libraries to choose a roofing style that complements the overall aesthetics of the building. This ensures that the library maintains its architectural appeal while benefiting from the practicality of FRP roofing panels. Moreover, FRP panels provide excellent insulation properties, helping to regulate temperature and reduce energy consumption within the library. This can contribute to a more comfortable and energy-efficient environment, enhancing the overall experience for library visitors. Furthermore, FRP panels are easy to install and can be customized to fit specific design requirements, allowing libraries to create unique roofing solutions. They can be easily cut, shaped, and installed, making the installation process efficient and hassle-free. In conclusion, FRP roofing panels are a suitable choice for libraries due to their durability, design flexibility, insulation properties, and ease of installation. Utilizing FRP panels for library roofs can provide long-lasting protection, enhance architectural aesthetics, promote energy efficiency, and ensure a comfortable environment for library-goers.

Send your message to us

2.0mm Thick FRP Panels for Trailer Roofs - Fiber Reinforced Plastic Sheet Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords