FRP Roofing Panel - Hot Pressed SMC Sheet for Water Tanks with Superior Anti-Corrosion

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

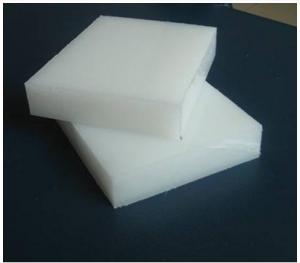

SMC and BMC are abbreviations of respectively Sheet Molding Compound and Bulk Molding Compound. SMC and BMC form a family of structural, fiber reinforces thermosetting resins. SMC and

BMC are intermediate materials from which a large variety of products can be manufactured by compression molding or injection molding. Base materials of SMC and BMC are, generally spoken, unsaturated polyester resins, glass and mineral filler materials, such as chalk or aluminum trihydrate. The composition of the compounds can be adapted to the application where it is used for. Specific properties such as flame retardancy, surface quality and paintability can be achieved by adding specific, functional materials. SMC and BMC product are used in a very broad range of applications

Product Traits

It is the water tank of new type adopted in the world presently,and is assembled by wholly good qualitied SMC plates.

We can assemble water tank with volume from 1m3 to 1000m3, easy to change the volume.

Sealing belt is non-toxic with high elastic property and fastened which means it has high strength.

It’s widely used in mine industry, enterprises&public institutions, house, hotels etc.

Food grade resin is adopted, so the quality of water is good and clean, without pollution, high strength, light weight, corrosion resistante, nice appearance, long service life, easy to maintenance etc.

Advantages

Sheet Molding Compound is a fiber-reinforced material, which consists primarily of a thermosetting resin glass fiber.

With high tech material—SMC, which has high impact compressive, flexural and tensile strength along with temperature stability.

Technical Parameter & Specification

| Properties | Unit | Value | |

| Appearance | - | Smooth surface, no airbubble and crack,no sundries | |

| Density | g/cm3 | 1.85~1.92 | |

| Water absorption | mg | ≤20 | |

| Molding shrinkage ratio | % | ≤0.15 | |

| Heat distortion(A) | °C | ≥220 | |

| Impact strength (Charpy in-notched) | KJ/m2 | ≥90 | |

| Flexural strength | MPa | ≥135 | |

| Insulationresistance | Under normalconditions | Ω | ≥1.0×1013 |

| Immerged inwater for24 hours | ≥1.0×1012 | ||

| Dielectric Strength(in 90°C oil) | MV/m | ≥12.0 | |

| Dissipation Factor(1 MHz) | — | ≤0.015 | |

| Permittibity(1 MHz) | — | ≤4.5 | |

| Arc Resistance | S | ≥180 | |

| Proof Tracking Index(PTI) | V | ≥600 | |

| Flammability | Class | FV0 | |

| Temperature | — | ≥155 | |

Application

The water tank has been widely used in residential buildings, hotels, office buildings, R&D buildings, schools, malls, restaurants and other public facilities as well as places with high requirements for water quality, such as hospitals and food processing plants.

FAQ

How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

- Q: Are FRP roofing panels resistant to impact damage from falling debris?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to impact damage from falling debris. FRP panels are manufactured using a combination of fiberglass and plastic resin, which makes them strong and durable. They are designed to withstand various weather conditions and are known for their impact resistance. This makes them suitable for areas where there is a risk of falling debris, such as in industrial or construction sites. However, it is important to note that the level of impact resistance can vary depending on the specific brand and quality of the FRP roofing panels. It is always recommended to consult with the manufacturer or a roofing professional to ensure that the chosen FRP panels are suitable for the specific application and expected impact loads.

- Q: What is the installation process for FRP roofing panels?

- Typically, the installation process for FRP (Fiberglass Reinforced Plastic) roofing panels involves the following steps: To begin, the roof surface must be thoroughly cleaned and prepared for installation. This may include the removal of existing roofing materials, cleaning the surface, and ensuring it is smooth and clear of any debris or protrusions. Accurate measurements of the roof are then taken to determine the required size and number of FRP panels. These panels are subsequently cut to the appropriate dimensions using a saw or similar cutting tool. It is important to wear safety glasses and gloves when cutting FRP panels for protection. Next, the first panel is positioned at the edge of the roof and securely fastened using suitable fasteners such as screws or nails. The subsequent panels are then overlapped with the previous one and also fastened down in a similar manner. This overlapping technique ensures a watertight seal and prevents any water infiltration. Once all the panels are successfully installed, any gaps or joints between them are sealed using a suitable sealant. This further enhances the waterproofing properties of the roof. Additionally, trim pieces may be used to cover exposed edges or corners, providing a more polished appearance. To ensure a proper and durable installation, it is crucial to carefully follow the manufacturer's instructions and guidelines. If you are unfamiliar with the installation process or have any doubts, it is recommended to consult with a professional or experienced contractor.

- Q: Are FRP roofing panels resistant to cracking?

- Yes, FRP (Fiberglass Reinforced Panels) roofing panels are highly resistant to cracking. FRP panels are composed of a strong fiberglass layer that is reinforced with a polymer resin, making them highly durable and resistant to various forms of damage, including cracking. The fiberglass layer provides exceptional strength and flexibility, allowing the panels to withstand heavy impacts and resist cracking even under extreme weather conditions such as hailstorms or strong winds. Additionally, FRP roofing panels are often designed with special additives that further enhance their resistance to cracking. However, it is important to note that while FRP panels are highly resistant to cracking, their durability may vary depending on the specific brand, quality, and installation method. It is advisable to consult with a professional roofing contractor or manufacturer to ensure proper installation and maintenance of FRP roofing panels for optimal performance and longevity.

- Q: Can FRP roofing panels be used for pergolas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for pergolas. FRP panels are lightweight, durable, and resistant to weather elements, making them an ideal choice for pergolas. They provide protection from the sun and rain while allowing natural light to pass through, creating a comfortable outdoor space. Additionally, FRP panels are easy to install and maintain, making them a popular option for pergola construction.

- Q: Are FRP roofing panels resistant to snow or ice build-up?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to snow or ice build-up. Due to their smooth and non-porous surface, snow and ice are less likely to accumulate and stick to FRP roofing panels.

- Q: Can FRP roofing panels be used for outdoor structures?

- Yes, FRP (Fiber Reinforced Plastic) roofing panels can be used for outdoor structures. FRP roofing panels are known for their durability, strength, and resistance to weather elements such as UV rays, rain, and wind. These panels are designed to withstand harsh outdoor conditions and provide excellent protection for various structures. They are commonly used for outdoor applications such as patios, pergolas, carports, sheds, and agricultural buildings. In addition to their weather resistance, FRP roofing panels are also lightweight, easy to install, and have a long lifespan. Overall, FRP roofing panels are a reliable and practical choice for outdoor structures.

- Q: Can FRP roofing panels be used for covered walkways?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for covered walkways. FRP panels are lightweight, durable, and have excellent weather resistance, making them a suitable choice for creating covered walkways that protect pedestrians from rain, snow, and sunlight. Additionally, FRP panels are available in various colors and designs, allowing for customization and aesthetic appeal in walkway designs.

- Q: Are FRP roofing panels suitable for historic buildings or preservation projects?

- FRP (Fiberglass Reinforced Plastic) roofing panels are generally not recommended for use in historic buildings or preservation projects. These types of buildings often possess unique architectural features and require special attention to preserve their historical significance. One of the main concerns with FRP roofing panels is their visual impact. Historic buildings are typically associated with specific materials, such as clay or slate tiles, wooden shingles, or metal sheets. Using FRP panels can disrupt the visual harmony of the building, potentially detracting from its historical character. Moreover, FRP roofing panels may not meet the strict preservation guidelines and regulations that often apply to historic buildings. Preservation projects usually aim to maintain the original materials and construction methods, ensuring that the building's historical integrity is preserved. Introducing modern materials like FRP panels can be seen as a departure from these preservation principles. Additionally, FRP panels may not possess the same durability and longevity as traditional roofing materials. Historic buildings often have roofs that have lasted for decades or even centuries, showcasing their resilience and craftsmanship. FRP panels, on the other hand, may have a shorter lifespan and may require more frequent maintenance and replacements, which can be detrimental to the preservation efforts. In summary, while FRP roofing panels may offer certain advantages such as affordability and ease of installation, they are generally not suitable for historic buildings or preservation projects. These buildings require a more sensitive approach that prioritizes the preservation of their historical character and materials.

- Q: Do FRP roofing panels have a warranty?

- Yes, FRP roofing panels typically come with a warranty. The specific duration and terms of the warranty may vary depending on the manufacturer and the specific panel model. It is advisable to check with the manufacturer or supplier for detailed information regarding the warranty coverage and any conditions or limitations that may apply.

- Q: Can FRP roofing panels be used in churches or religious buildings?

- Yes, FRP roofing panels can be used in churches or religious buildings. FRP panels are lightweight, durable, and offer excellent weather resistance, making them suitable for various architectural applications. They can withstand extreme temperatures, UV radiation, and are designed to provide long-lasting protection. Additionally, FRP panels can be customized to match the aesthetics of the church or religious building, allowing for a seamless integration with the overall design.

Send your message to us

FRP Roofing Panel - Hot Pressed SMC Sheet for Water Tanks with Superior Anti-Corrosion

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords