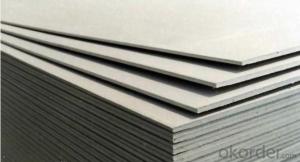

Fiber Cement Board Square Fiber Cement Board Square

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The tile is made by high-density fiberglass with compound decoration wool

on the surface and fiberglass wool on the back .The edges are painted. With the

characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The titles are manufactured from high density dry felf resin bonded fiberglass wool, with fine texture painted glass tissue facer,plain tissue backer and sealed and painted edges.square edge titles will be paralled to suspension system after installation.

Product Advantages:

1)Incombustibility/Non-flammability: Consmos Calcium silicate board is non-flammable and conforms to the national grade A standard (GB8624 Grade A) with excellent fire resistance property. In case of fire, the board will not burn and not give off toxic smoke.

(2)Thermal/heat insulation: Owing to low heat conductivity, the product has good performances on keeping warm and heat insulation.

(3)Water-proofing and moistureproof: The product is allowed to long-term exposure to moist environment but still very stable. The board still keeps intact after being soaked in water for one month, the phenomenon of swelling and out of shape will not happen. It has good adjusting mechanics like woods. Even it is used on wash house.

(4)Endurance/durability: Consmos Calcium silicate board provides good insulation against bugs, fungus and corrosion. It can last for a long time and will not corrode.

(5)Noise-proofing: Consmos Calcium silicate board provides good insulation against noise.

(6)High-Strength and Light weight: The board is light weight, in this case, it can decrease weight of building greatly. At the same time, the material is high-stength and not easy to be damaged.

(7)Easiness to installation: The construction process does not require complicated tools but just the ones used in regular wood construction. Our board can be fixed on light steel frame with self-attachable screws or a glue gun to nail the bolts into the wooden frame.

(8)Environmental protection: Consmos Calcium silicate board is 100% free of asbestos fiber and will not cause any harm to human body or the environment.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q: the cement boards are ahold by 1 nails

- Hardyboard is a composite/concrete siding that may work. If your boards are only slightly damaged you may be able to patch them with concrete patch then repaint. A lot cheaper than replacing.

- Q: What is the prc in the building?

- Prestressed reinforced concrete

- Q: What is the difference between a cement pressure plate and a cement board?

- Cement pressure plate, also known as fiber cement pressure plate or cement fiber pressure plate, is a natural fiber and cement as raw material, by the pulp, forming, cutting, pressing, curing a new type of building plate. Is a new generation of "green" building materials, in the excellent moisture, fire performance based on the unique environmental protection features. It is based on siliceous and calcareous materials as the main substrate, with cellulose fiber reinforced materials, mixed with other auxiliary materials, through the copy forming, high pressure curing the formation of a new type of building materials. With light, high strength, waterproof, anti-corrosion, fire, large format, good processing, improve construction efficiency and so on. Widely used in civil and industrial buildings. Can be used for building floor, interior wall panels, exterior panels, ceiling panels, curtain wall panels, composite wall panels, insulation materials, roofing and other parts.

- Q: This is behind my vinyl siding and above my drop tile ceiling.

- It would most likely be asbestos because nobody in there right mind would cover Hardi with vinyl.

- Q: Help? Do I just lay new thinset on top or what?

- i've got laid some tile, flooring,showers, and a pair tables(greater of the mosaic form). i'm exceedingly beneficial which you're able to desire to apply hardibacker(cement board) purely for showers or kitchen/tub flooring. it somewhat is substantial objective is to evade any air /moisture from seeping up with the aid of the backside ,for this reason inflicting the tiles to interrupt. Hardibacker helps seal all that out. yet i do no longer think of it somewhat is mandatory on your project. you will no longer could difficulty approximately spilled drinks after your table is cured and sealed. The grout is what keeps something from getting below your tiles. be certain you wait a minimum of 24 hours earlier sealing your new tile activity. perhaps look into a tile e book from the library or seem up How-to do -it your self form of web sites for education. stable success!

- Q: i can ollie on a rug ok but then on the cement my board moves and the back wheels dont get up i know i am doing the ollie right but when i try it on the cement the board moves and the back wheels dont go up i really need help because most of my friends skate and they are really good and i would like to start skating but i dont know if i am good please give me some tips about ollieing on the cement thanks!

- Your pushing your board back with your feet. Try not to do this and practice. The only way to be good in skateboarding is practicing everything hard.

- Q: How much is the cement board?

- Good and bad can not say that you use there. It is in the construction and decoration are used on a wide range of .For example, the bathroom grid wall building exterior to do the shape. Fine decoration useful to make it decorative layer, the pursuit of some special The artistic effect.

- Q: i glued a piece of regular printer paper to a piece of matboard as part of an art project. since i applied rubber cement to both the paper and the board, it bonded quite strongly. the problem is that now i have to remove the paper with the least amount of damage to the matboard. the paper is white and the board is black. its been over a week since i glued the two together. HELP!! i need this for school and it has to look good...any suggestions??im going to throw the paper away, so that can be damaged in the process. no problem.

- hair dryer to warm it and peel real slow...?

- Q: The scope of application of foam cement

- Pipeline backfill. Underground abandoned oil tanks, pipelines (built-in crude oil, chemicals), sewage pipes and other holes easily lead to fire or landslides, the use of foam concrete backfill can solve these troubles, the cost is also less. The density of foam concrete depends on the diameter of the pipe and the groundwater level, usually 600-1100kg / m? ;.

- Q: or can i leave the seams alone? if i have to tape them what tape do i need and what compound do i need? thanks for any help!

- There's no need to tape the seams of cement board, as long as you get a good close fit it should be ok. You've made a wise choice using cement board, at least on the lower half of the shower enclosure area, greenboard, while being somewhat moisture resistant is not impervious to water damage. It should be used above the cement board and will do a good job there. The seams in it will need to be taped, at least above the top edge of the surround.

Send your message to us

Fiber Cement Board Square Fiber Cement Board Square

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords