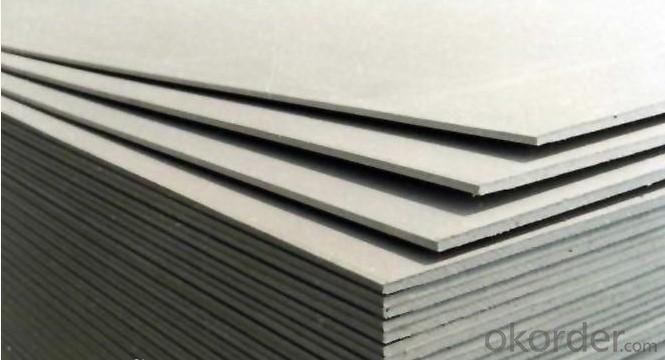

Fiber Cement Board Gray Fiber Cement Board Gray

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

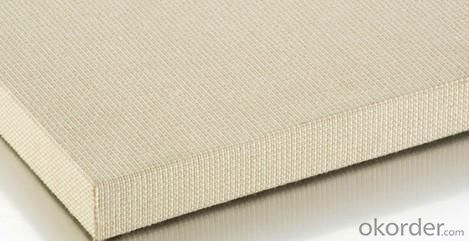

The tile is made by high-density fiberglass with compound decoration wool

on the surface and fiberglass wool on the back .The edges are painted. With the

characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The titles are manufactured from high density dry felf resin bonded fiberglass wool, with fine texture painted glass tissue facer,plain tissue backer and sealed and painted edges.square edge titles will be paralled to suspension system after installation.

Product Advantages:

1)Incombustibility/Non-flammability: Consmos Calcium silicate board is non-flammable and conforms to the national grade A standard (GB8624 Grade A) with excellent fire resistance property. In case of fire, the board will not burn and not give off toxic smoke.

(2)Thermal/heat insulation: Owing to low heat conductivity, the product has good performances on keeping warm and heat insulation.

(3)Water-proofing and moistureproof: The product is allowed to long-term exposure to moist environment but still very stable. The board still keeps intact after being soaked in water for one month, the phenomenon of swelling and out of shape will not happen. It has good adjusting mechanics like woods. Even it is used on wash house.

(4)Endurance/durability: Consmos Calcium silicate board provides good insulation against bugs, fungus and corrosion. It can last for a long time and will not corrode.

(5)Noise-proofing: Consmos Calcium silicate board provides good insulation against noise.

(6)High-Strength and Light weight: The board is light weight, in this case, it can decrease weight of building greatly. At the same time, the material is high-stength and not easy to be damaged.

(7)Easiness to installation: The construction process does not require complicated tools but just the ones used in regular wood construction. Our board can be fixed on light steel frame with self-attachable screws or a glue gun to nail the bolts into the wooden frame.

(8)Environmental protection: Consmos Calcium silicate board is 100% free of asbestos fiber and will not cause any harm to human body or the environment.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q: Will the reinforced concrete cement board be soaked in water for a long time?

- Reinforced concrete (English: Reinforced Concrete or Ferroconcrete), engineering often referred to as reinforced concrete (tong). Refers to a composite material that improves the mechanical properties of a concrete by cooperating with a composite material consisting of reinforcing steel bars, steel plates or fibers in concrete. For the most common form of stiffened concrete.

- Q: What is the weight of the generally insulated panels? As much as possible to list some, thank you prawn

- In addition, this product can not be used for external wall insulation panels, deformation may not be able to hang down, down, dangerous. High-density cement fiberboard water absorption is too large, heavy weight.

- Q: Where is the cement pressure plate installed?

- Wood keel plus cement pressure plate: The most construction method, the construction of the most simple, easy. Disadvantages: wood keel in the bathroom humid environment is easy to absorb water, mold, resulting in deformation, so that the chip fried. Remedy: After installation, paste the front of the anti-root tube to do waterproof, to prevent the ground water into the riser, immersed in the wood keel.

- Q: the cement boards are ahold by 1 nails

- those are probably asbestos! caulk the damages with acrylic latex and paint.

- Q: I am in the Chicago area and it rained a few days ago.... I am also using molds and wood 4x4's

- You can pour the cement one day and let it dry over night --You should be able to nail the boards onto it the next day. Wait for a day with (no rain) to pour cement. We just built a fence and poured the cement and it set up real well by the next day--but it was not raining. Good Luck on your fence

- Q: I'm making designs for a house I want to build. Initially I wanted to build the house out of primarily concrete, however because of where the house is going to be going, it's not really plausible to get that amount of concrete out there to pour at once (it would be extremely difficult to get a truck out there).So my next consideration would be to build an otherwise traditional frame and instead of using drywall on the inside, I would use cement boards to panel the walls, and go for a clean, future-industrial look. I was also intending on doing something similar to the exterior.However, cement boards obviously weigh significantly more than typical drywall panels, and my main concern is whether or not a regular wood frame would be able to hold that amount of weight. So would that pose a significant issue to the extent that I should also consider using steel for the entire frame, or at least as a support system, or should wood be able to hold up just fine?

- Wood is fine. I am building a house that is using the 1/2 HardieBacker cement board panels attached to sound channel that is attached to wood studs. Works well. Building Dept approved it.

- Q: We are building a new house and I am going to install tile in the bathrooms myself, we have the drywall hung and will be sanded in the next day or two. My question is, can I go ahead and hang the Cement backer board in the showers? or do I need to wait until the drywall is sanded or primed? Thanks :o)

- Hang it now, you'll be fine.

- Q: how do I lay cement board on a concrete floor with out screws?

- Why do you want to? If you're laying tile, just use a thinset made to bond to cement.

- Q: I need to fix a loom board cause one of the pegs broke we don't have superglue but we have vinyl cement can I use that?

- whoa down kimosabe glue of anykind will fail any and all trust me take a pair of pliers and break the peg off flush the proper fix is to drill and set a new peg and wood glue would be your best choice a faster option is to use a nail in place of the peg not the same diameter i know use masking tape to increase the diameter of the nail fast ez no glue drying time

- Q: I have a friend who owns a house who believes it was built in 1968. The basement is in immaculate condition-- completely dry. The walls are poured cement and you can see where the forms were taken off the wall after it was poured. My question -- did they pour walls back in 1968 or was cinder block the building material used? I think the house was renovated within the last 15 years. My friend and I are baffled. Thanks!

- Yes we had concrete back then, and yes they did pour walls, in 1968, cement was used in the days of the Romans, I am 70 yrs old and in 1968 i was getting discharged from the Army, [19 yrs old ] cinder block wasn't,t used for foundation ,s al tho most people think , we were still in the dark ages back then, we had cars that got 30 to 40 mpg, wages were $4.50 an hr we walked to school. and didn't, lock our Doors at night. and had to pump our water, and split wood for heat,

Send your message to us

Fiber Cement Board Gray Fiber Cement Board Gray

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords