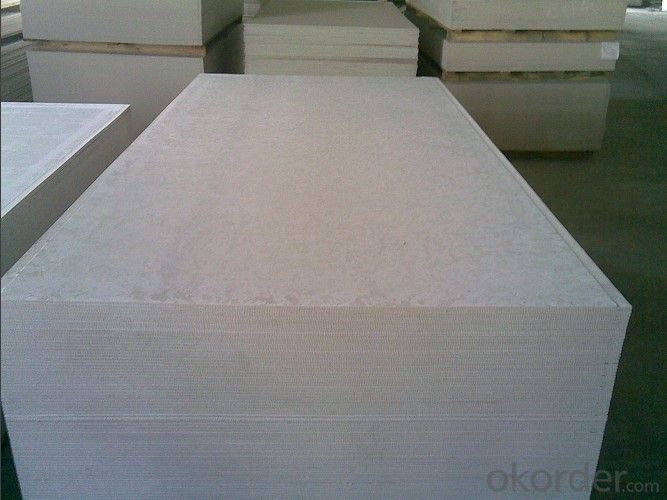

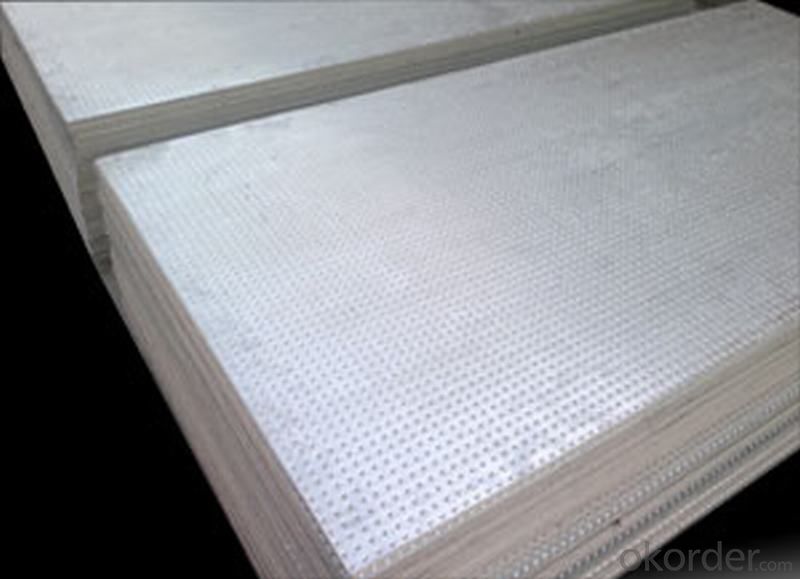

Fiber Cement Boards Fiber Cement Board For Floor

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

Product Applications:

Fiber cement board can be used in exterior wall cladding and facade of various high-class and high rise civil buildings especially in the modern luxurious buildings. Outstanding sound insulation of the system composed with Bysink external wall board can be used in indoor partition and suspended ceiling for the high demand in private request as sound insulation and such as five star hotel, bedroom, and public entertainment.

Also it can be used as the interior partition in the shops, hotels, schools, entertainment places and hospitals.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

1) Elegance and excellent decoration

2) Easy installation and convenient maintenance

3) Best Surface processed with PVC Lamination

4) Heat insulation, thermal insulation, moisture proof, mould proof, sound absorption and noise reduction

5) Incombustibility / Fireproof

6) No dust / no pollution

7) Stucturally strong

8) Over 15 years no transmutation

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q: What do I do

- it may be broke

- Q: My fear is that I will trap moisture where it shouldn't be. Is there such a thing as overkill?

- No problem. i dont call it overkill. I would rather do it know than wish i had.

- Q: the neighbor has a son and him and his friends constantly makes noise instigating trouble. I complain to the manager, it stops and than starts back up again a week later, so I rather put up something that can help

- Where I used to work we put up Cork Board 1 thick on the entire wall to help with the noise next door.

- Q: Light steel keel cement board is what

- Cement board is a cement as the main raw material processing and production of a building plate, is a between the gypsum board and stone, free cutting, drilling, carving of the building products, with its superior to gypsum board, wood fire , Waterproof, anti-corrosion, pest control, sound insulation and far lower than the price of stone and become the construction industry widely used in building materials. The cement board is prefabricated and also cast.

- Q: We have an older house (1957) that has 1 thick beams as a substrate floor. Currently, there is 1/2 plywood on top of the substrate floor. We are going to rip this up so that we can apply mortar to the substrate for leveling purposes. We would put the porcelain tile directly on top of the cement board.The guy at Home Depot (a former contractor) said we can just use 1/2 cement board directly on top of the substrate floor without a layer of plywood underneath. The substrate is old, but sturdy real-wood diagonal beams that lay on top of the joists. He said they are plenty strong and we don't really need to add a plywood subfloor if we use 1/2 thick cement board.What do you think? Do you think we could get away will laying down cement board on top of the substrate floor without plywood for added strength?Thanks!

- If you have any reservations about the strength of using just the compressed cement board, why not lay that compressed cement board on top of the ply that's there now and save the hassle of ripping it up and quell those doubts. As for using a mortar for leveling purposes, why wouldn't you just use a tiling compound to rectify the levels as your tiling. After all how bad could it be, as a carpenter I'd say the guy who built the sub-floor frame couldn't have been more than a few mils out, here of there. BTW the compressed cement board will easily take the load without the ply.

- Q: My fear is that I will trap moisture where it shouldn't be. Is there such a thing as overkill?

- Tile council of America calls for a vapor barrier behind the cement board ..The red guard your talking about should and must be used on any horizontal surface in a wet area.. There are other agents like red guard but I v used it many times and had great luck w/ it..Making sure the proper pitch is used for the horizontal surface GL

- Q: Can someone tell me if they know or what they would think is stronger, six cement blocks stacked high or a board that is 6 feet long and 6 by 6?

- are the cement blocks stacked without mortar? are the cement blocks loaded in bending or compression? is the board loaded in bending or compression? What is the criterion of failure? cracking or breaking? Not a fair comparison with out some explanation.

- Q: hi, this is my question:To prevent a cement mixer sinking into soft ground, the mixer is placed on a large flat board. Why does this prevent the mixer sinking?the answer will be one of these, which one is it?A The large area decreases the pressure on the ground.B The large area increases the pressure on the ground.C The large area decreases the weight on the ground. D The large area increases the weight on the ground.

- None of the above. The pressure and weight on the ground is greater with a board under the mixer. However, the board distributes the weight across a larger surface area thereby reducing the pressure at any given point.

- Q: I want to lay some tile on a portion of the garage where we are putting in a small kitchen for garage use. If the floor is new would you have to lay cement board down on top of new cement before tiling?

- You don't EVER have to lay cement board over concrete. Just check it with a straightedge and fill in any low spots before you lay the tile. Good luck.

- Q: A list of US suppliers is here w/ some discussion.

- Haven't experienced it but from what I read in your link, it gets hung/nailed like drywall and underlayment. If you're not familiar with how to hang drywall, the first link is a very informative step by step video. Second link, though not a video is how to install cement board/fiber underlayment. Hope this will be of help to you - good luck!

Send your message to us

Fiber Cement Boards Fiber Cement Board For Floor

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords